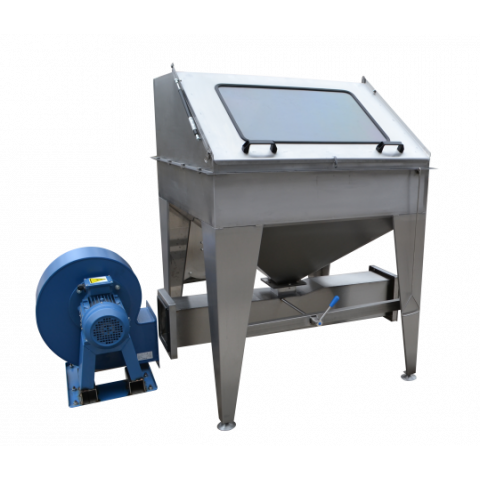

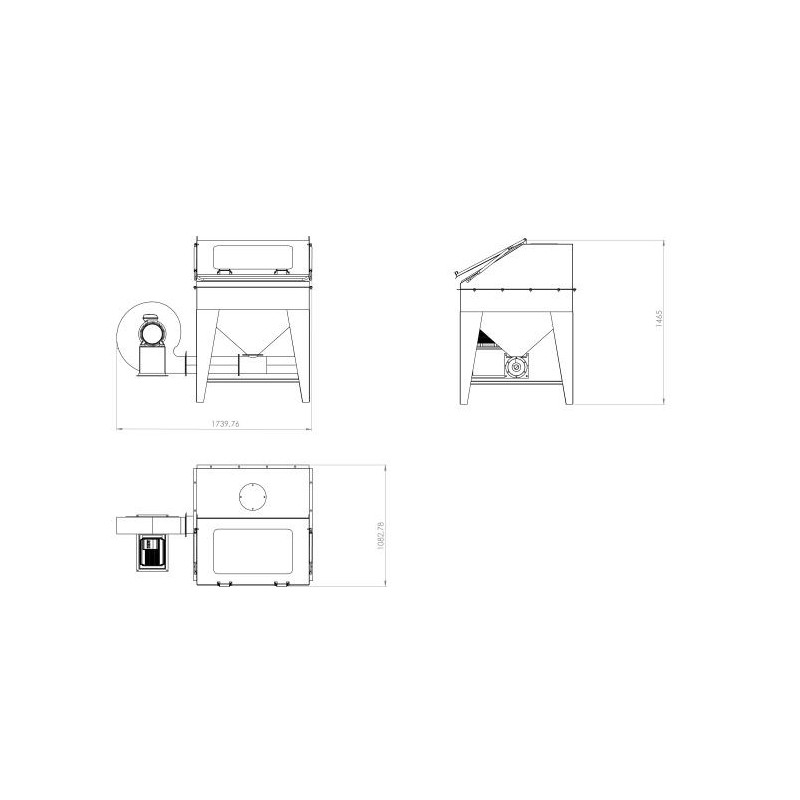

Big bag discharge station BBDS

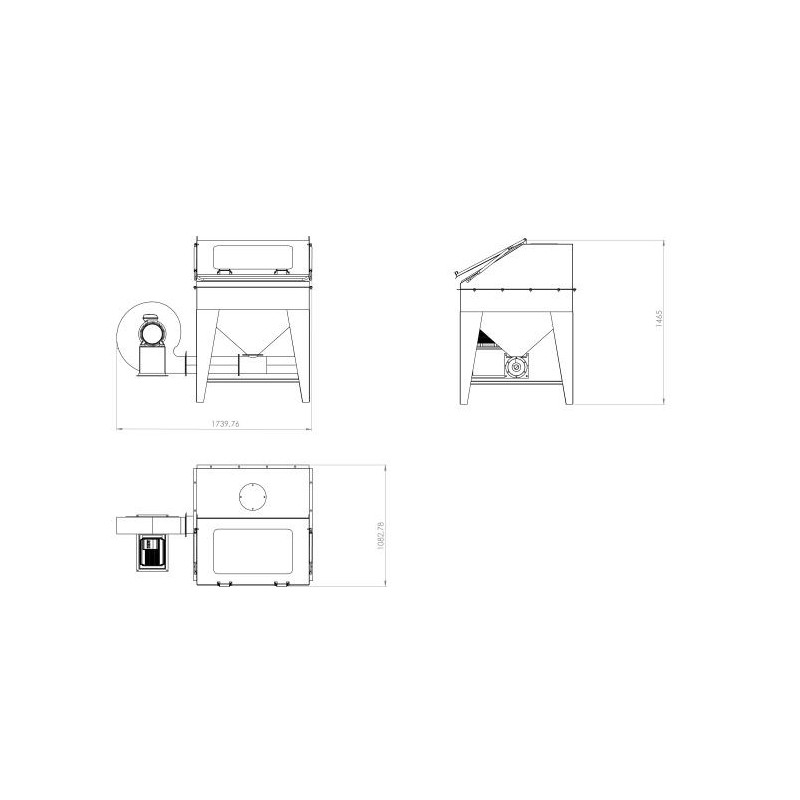

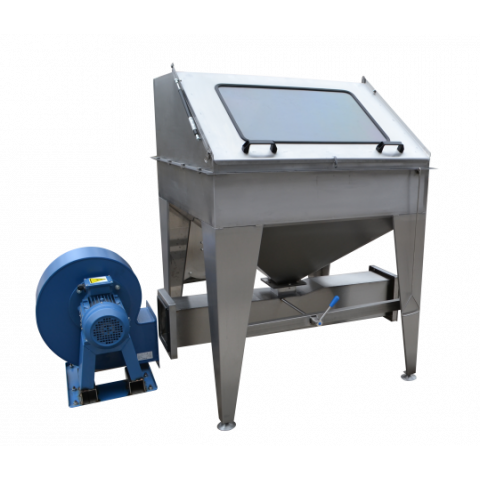

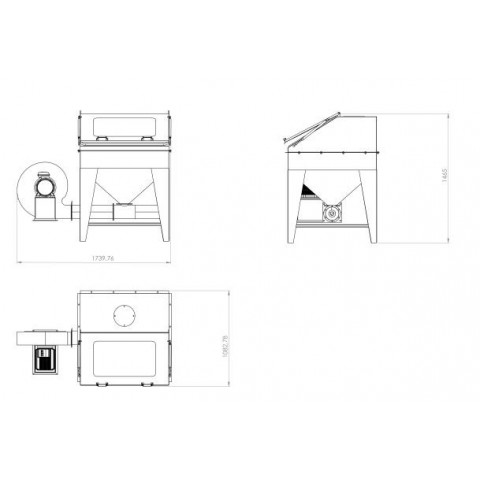

The big bag dosing/discharge station is designed to dispense powder blends big bags with a weight of 30kg with a built-in fan.

The Big Bag Dosing Station is a device that serves to dispense powder blends big bags with a weight of 30kg with a built-in fan.

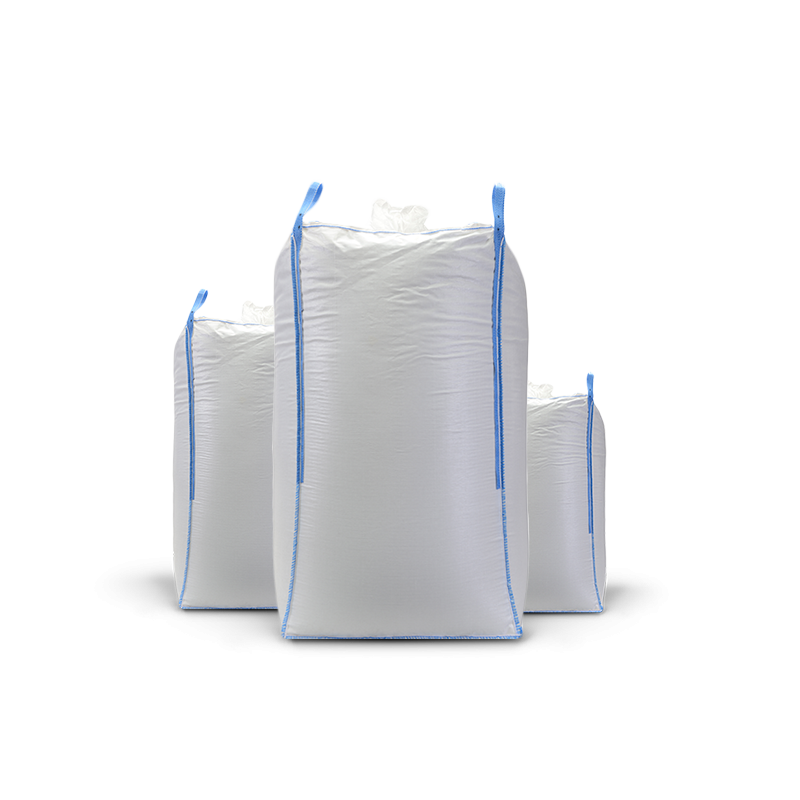

Designed for the systematic extraction of bulk powder or granular materials (cement, sugar, gypsum, soda, chalk, carbon black, flour, cocoa and others) from bags and bags. The station for emptying big bags is a versatile and powerful device that is used for optimally and automatically emptying out big bags with various food products.

Areas of use:

- Pharmaceutical industry

- Food industry

- Chemical industry

- Glass industry

Usage

- Chemicals

- Fertilizers

- Laminate

- Food products

- Grains

- The shotcrete surface

- Pigments

- Construction Materials

- Seeds

- Peanuts

- Starch

- And others

The working principle is very simple

Large bags are placed on the dose (discharge stations) manually or┬Āwith a help of a dumping machine. By the closing of the cover, we prevent accidental leakage of material being dispensed. Manually or pneumatically activated emptying mechanism provides a safe and dust-free complete emptying of the bag. In the modular production line installation, we recommend as (instead of dosing equipment) is to use pneumatic conveyor/cyclone.

Benefits of equipment

- easy operation

- with an integrated knife to cut

- dust-free emptying due to an openable cover

- rapid exchange of big bags

- applicable to all sizes of big-bags

- a high degree of rationalization

- maximum operator safety

- quick return on investment

- material design: parts in contact with material made of stainless steel

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

You might also like

Bin tipper/dumper with pneumatic lift VBB is a device suitable for lifting and emptying big bags, plastic bags and boxes with food and other materials.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

Multifunctional barrel dumper is designed for efficient and simple handling of plastic and steel barrels.

- Principle of operation: Batch mode

- Voltage: 220-230V

The big bag discharge station is designed for the efficient handling of bulk products stored in big bags up to 1500 kg. The machine is a perfect solution for the food, chemical, pharmaceutical, and construction industries. This type of equipment is suitable for a wide range of bulk products from seeds, cocoa, beans up to construction materials such as dry gypsum, cement, etc.

Device for tipping barrels with products

- A locking hook under the barrel protects and holds the steel barrel

- Safety drawbar with a single-hand operation and 3 functions (lifting/lowering/moving)

- Foot pedal ensures precise lifting

- Optimum operator protection thanks to the extended handle and protective grid

- Material: Steel

- Operation mode: Manual

- Type of the equipment: Individual machine

The bin tipper MGBT is a device suitable for lifting and emptying crates used in agriculture.

- Productivity: 3000 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

A bin tipper is used for unloading fruits and vegetables from plastic or wooden pallet containers. It can be used for variety of products such as different fruits and vegetables.

For more information, send us a request.┬Ā

- Material: Stainless steel

- Principle of operation: Batch mode

The machine is designed for total or partial unloading of a 200 liter trolley with meat mass (200 liter bin).

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

The box tipper VK is designed for semi-automatic emptying of boxes/containers/crates with all kinds of root, tuber vegetables, and fruits.

- Principle of operation: Batch mode

The big bag discharge station is designed for the efficient handling of bulk products stored in big bags up to 1500 kg. The machine is a perfect solution for the food, chemical, pharmaceutical, and construction industries. This type of equipment is suitable for a wide range of bulk products from seeds, cocoa, beans up to construction materials such as dry gypsum, cement, etc.

A hydraulic crane hoist with a hook is a mechanical device designed to lift and move heavy machinery or engines, commonly used in industrial settings as well as automotive repair for safe and efficient handling of heavy loads.

- Type of the equipment: Optional equipment

Bin tipper/dumper with pneumatic lift VBB is a device suitable for lifting and emptying big bags, plastic bags and boxes with food and other materials.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

An ideal solution that greatly facilitates and speeds up the work of the attendants, without having to lift and turn the bowl in order to transfer the dough to another dosing or portioning machine, for example, to another batcher or portioner.

- Material: Stainless steel

Multifunctional barrel dumper is designed for efficient and simple handling of plastic and steel barrels.

- Principle of operation: Batch mode

- Voltage: 220-230V