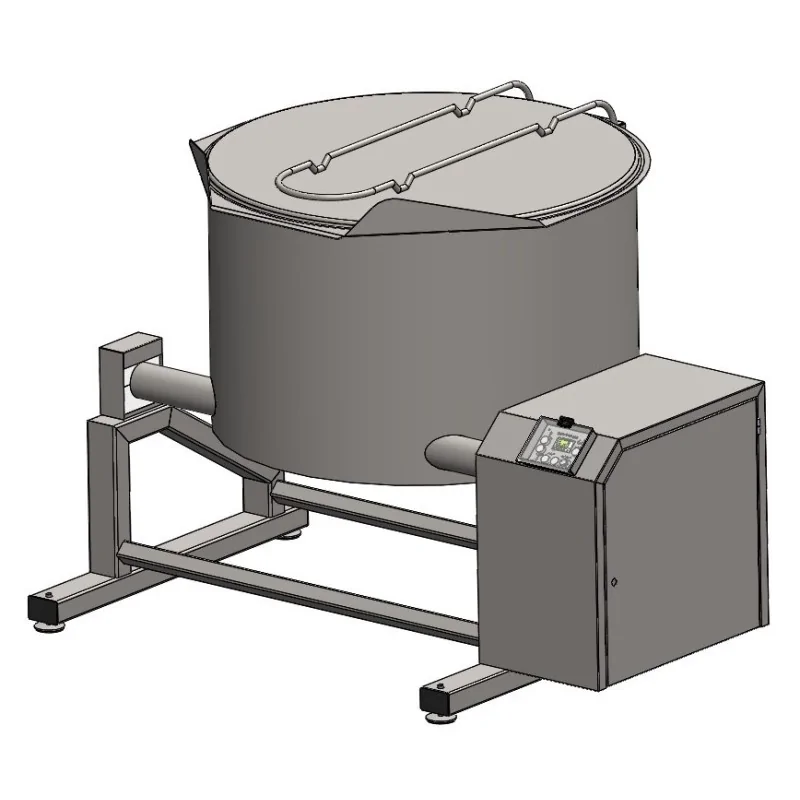

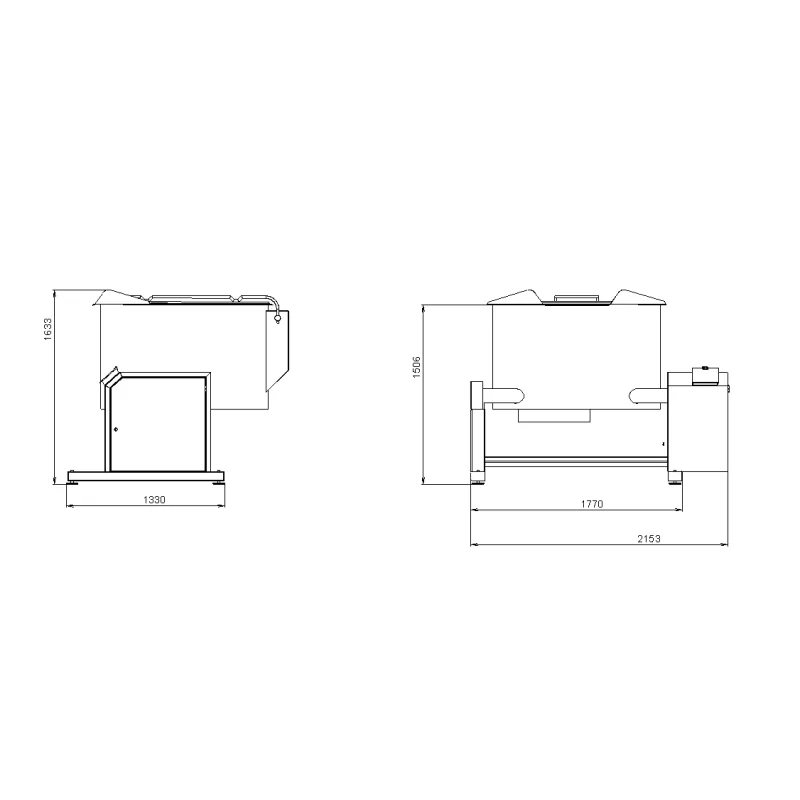

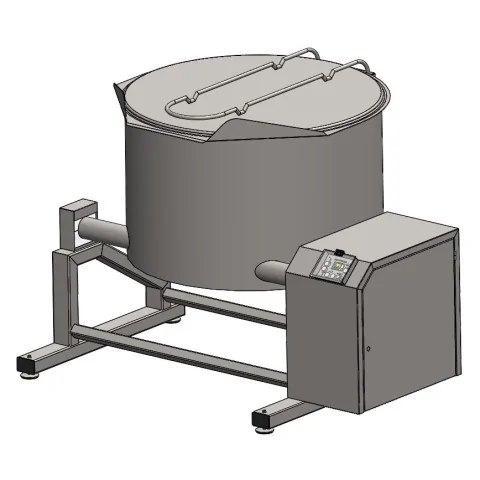

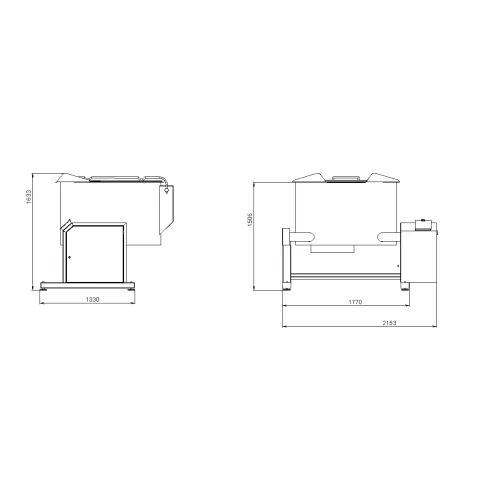

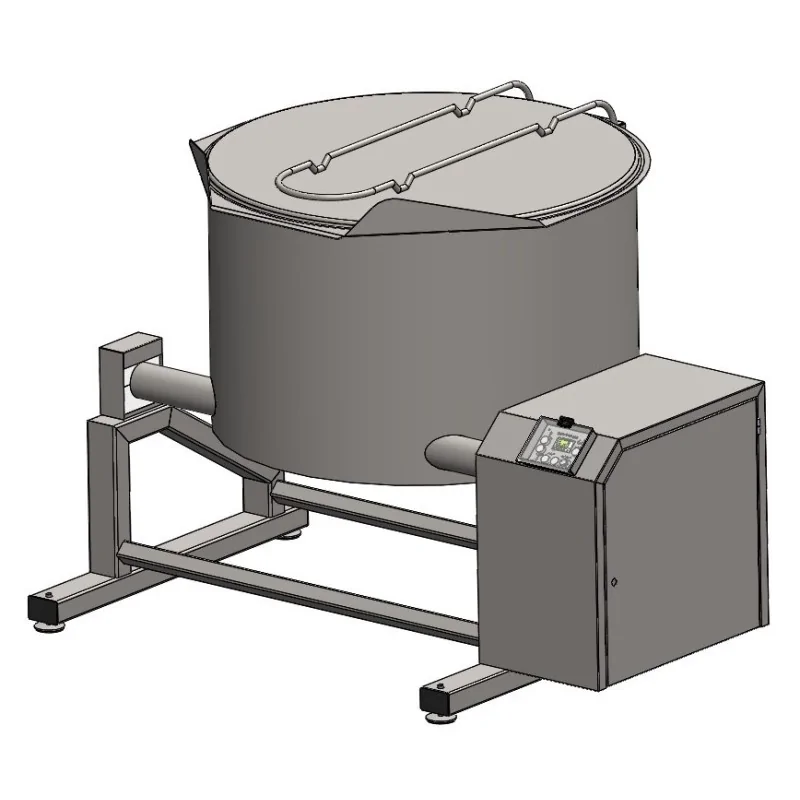

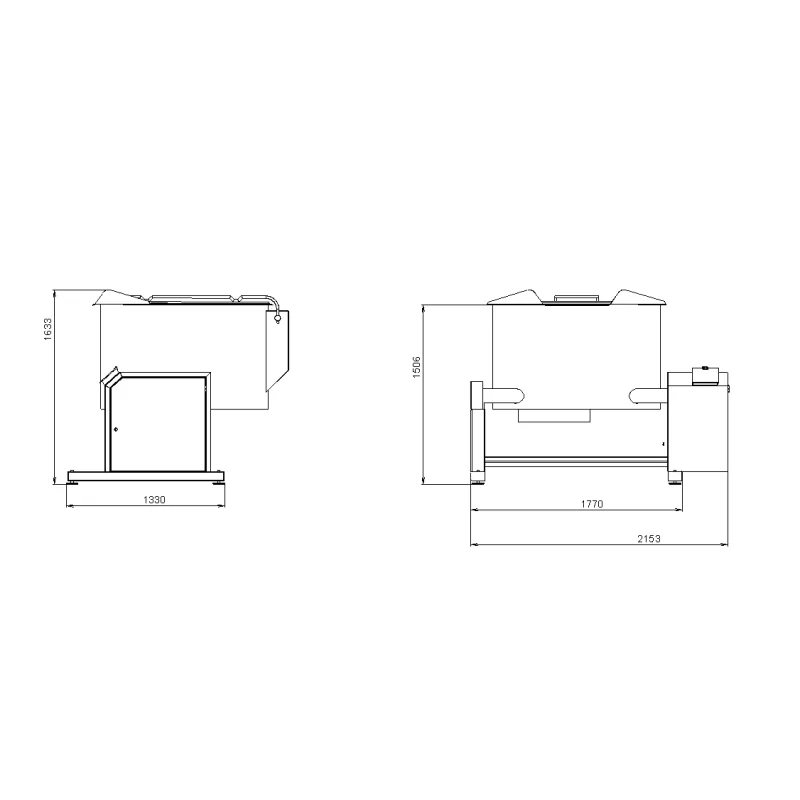

Salad mixing machine 600-1000

Equipment for mixing multi-component mixtures of products, such as vegetable salads with various dressings, including thick and viscous ones like mayonnaise, thick sour cream and other similar sauces.

- Hydraulic tilting system is included in the basic version

- The controls are located directly on the frame supporting structure

- Eccentrically offset working shaft for rotating/tilting the working tank

- Low loading height

- The installation is made entirely out of food grade stainless steel

Mixing machines are designed for use in the food industry, particularly in the production of semi-finished products, ready-made in-flight meals, and cooking in small to medium-sized facilities, including dark "kitchen" setups.

The universal mixing unit is suitable for the gentle mixing of various foods such as leafy greens, salads, and other comparable products.

Advantages:

- Maximum product unloading with virtually no losses due to the hydraulic tilt of the working container and the eccentrically offset working rotation shaft.

- A special system for fixating the top cover for safe operation when tilting (loading/unloading) the unit.

- The height of the maximum tilt and unloading is based on the height of the rolling trolley (BIN container), standardly used in food production.

- The mixing device in the form of a "half-arm" has a special shape and bend for gentle, yet thorough mixing of the product; a flexible scraper is already included in the basic version for cleaning the walls of the working container.

- Automatic tilting and unloading system facilitated by the integrated hydraulic station within the supporting structure of the installation.

- Simple control system with an adjustable speed of rotation for the mixing device.

- Sensors for monitoring the position of the working container and an open lid, ensuring the operator's safety during operation.

- User-friendly design for easy cleaning, sanitization of the installation and simple, intuitive operation.

- Quick-release mixing device for simple and convenient cleaning/maintenance of the mixer.

Basic version

It comprises an atmospheric working container suspended by a rotation shaft mounted on the supporting structure/frame of the installation. The container features an electrically driven mixing device with a flexible scraper, a built-in hydraulic system, and a control panel.

- Material: Stainless steel

- Operation mode: Mixed

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 600l/ 1000l

16 other products in the same category:

These meat mixers are characterized by their modern design and strong AISI 304 stainless steel construction.

For more information, send us an email at sales@foodtechprocess.com

The vacuum homogenizer is designed for whipping mayonnaise, ketchup, various sauces, confectionery pastes and fillings, condensed milk, jams and marmalades, canned goods, as well as similar liquid or pasty products with a homogeneous structure.

- Homogenizer in an external circulation loop

- Built-in vacuum generation and retention system

- Modular design with numerous options

- Possibility of automatic dosing of ingredients (optional)

- No additional pump required for loading/unloading

- Automatic top cover lifting system

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 13,5

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Round cooking boiling pan combines together the advantages of cooking with automatic mixing. Designed for catering industry, school kitchens, restaurant kitchens or food industry. Capacity ranges from 100l to 500l. The available heating options are - steam boiling or indirect electric heating.

The mixer is designed for mixing large quantities of dough as well as meat mixtures.

SIPM pasta mixer is designed for medium size commercial operations, ideal for medium-size restaurants to produce any kind of pasta such as spaghetti, taglia pasta, cannelloni, macaroni, conchiglie, rigatoni, penne and many others. The price includes a pasta cutter.

For more information, send us an email at sales@foodtechprocess.com

The price is indicated for the basic version of the set of equipment with a homogenizer

The equipment for the production of ice cream mixtures is based on a universal vacuum reactor with a coolant jacket and a multi-stage dispersant/homogenizer in an external circulation loop.

- Special type of a stirring device for easy disassembly and cleaning

- Processing with minimal product loss

- The bottom outlet valve is included in the basic version of the installation

- Multi-stage disperser for intensive wetting and homogenization of the flowing mixture

- External circulation circuit with a three-way valve for operation/washing of the equipment

- Reinforced agitator drive for thick and viscous mixtures

- Built-in vacuum pump

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Total power, kW: 3

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The appropriate mixing equipment for drum processing depends upon the properties of the products and with the available drum opening.

For more information contact sales department at sales@foodtechprocess.com

Highly efficient production of a high viscosity pharmaceutical and cosmetic products.

For a price quote, send us an email to sales@foodtechprocess.com

Paddle Mixer type is designed for fast and precise mixing for meat-mass production in meat processing factories. Can also be used for mixing products such as spices or tea.

The new design of the universal cutter with gravity mixing is used for the production of thick and pasty products. The cutter is designed to carry out production processes such as cutting, mixing, crushing and emulsifying of various types of products to a liquid state. Thanks to the built-in duplicator, it can also be used as a device for the production of cream honey or cream honey souffl├®.

- Cutting knives with a powerful 11 kW electric drive

- Frame mixing device with fluoroplastic scrapers

- Hatch opening sensor for safe maintenance

- Plexiglass hatch for visual inspection

- Duplicator for the thermal liquid around the bottom as well as the walls of the installation

- Inclined design for efficient grinding, homogenization and discharge of thick and viscous products

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

- Total power, kW: 12

- Voltage: 380-400V

The tank is designed for heating and mixing chocolate, butter, margarine, honey and similar products.

For more information or a price quote, send us an email at: sales@foodtechprocess.com

Vacuum mixer processing plant for viscous products is an ideal solution for the production of pilot batches and the industrial manufacturing of a wide range of products from small to medium capacity.

Barrel mixers are used to mix a wide range of loose and granular products in a shipping/barrel container. The available mixer models are suitable for the following volumes:

ConMix 20 - 20-30 liter standard drums with a diameter of 316 mm, adjustable frame structure height

ConMix 75 - 48-65 liter standard barrels with a diameter of 400 mm, adjustable frame structure height

- It is possible to use standard food containers ranging from 20-65 liters

- Easy control via a frequency converter as a stand-alone control panel

- Safe operation thanks to a roll bar with a position sensor

- Engine power, kW: 0,37/ 0,55/ 1,1

The CH PROFI 400 Vacuum Cooking Equipment is a high-performance system tailored for professional kitchens and industrial facilities, streamlining production processes with its advanced vacuum and mixing technology, ensuring superior flavor and texture in food preparation.

We offer different capacity vacuum cookers. For more details and price, please email us at sales@foodtechprocess.com

The dough mixer is a batch type mixing equipment, working in the opposite direction, to produce a wide range of dispersions and emulsions of varying viscosity.