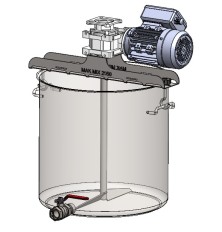

Meat processing equipment / Commercial meat mixer┬Ā

These meat mixers are characterized by their modern design and strong AISI 304 stainless steel construction. Part of the mixer is a tilting tank with automatic locking system and safety lock. It is a two mixing arms system. Stainless steel cover with safety microswitch. Minimum loading required: 40% max capacity.

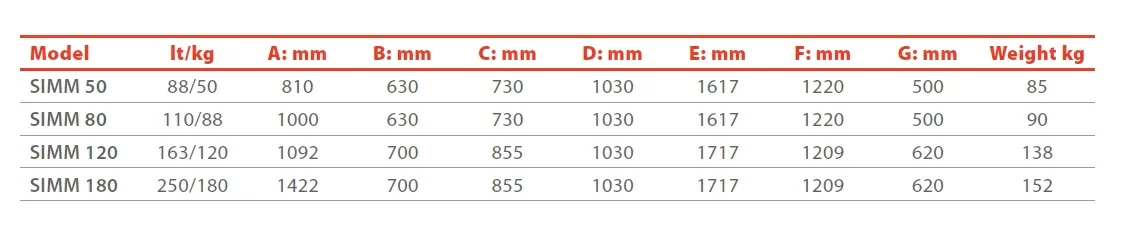

Meat mixer - technical specifications

- Stainless steel swivel wheels with lock

- Removable AISI 304 stainless steel mixing arms (no tools required)

- Total protection of gear box/control panel

- Oil-bath gear box, ground and tempered helical gears

Stainless steel IP 67 controls:

- forward and reverse

- auto-off feature

- auto-function with reverse

- Double seal on tank and gear box

Optional: Feeding tray to add ingredients.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 50l/ 110 l/ 163 l/ 250l/

You might also like

Hydraulic piston fillers for the food processing industry, filling machines for meat and sausages, ideal equipment for meat industry producers and butchers.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Volume: 20l/ 30l/ 50l

Heating boilers are designed to cook sausages, hams and o’¼Ćal. Technology for superior performance and hygiene.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 300l/ 400l/ 500l/ 600l/ 800 l / 1000l/ 1200l/

The mixer is designed for mixing large quantities of dough as well as meat mixtures.┬Ā

- Material: Stainless steel

- Engine power, kW: 1,5 / 2,2

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 80l/ 140l

- Voltage: 380-400V

Suitable for mixing a small amount of dough or meat as well as other thick mixtures.

- Material: Stainless steel

- Engine power, kW: 0,55

- Principle of operation: Batch mode

- Volume: 10l/ 20l

Meatball production line comprises of a filler, automatic machine for making meatballs and batter-breading machine. Price depends on your production capacity.

- Productivity: 15 000

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 220-230V

Atmospheric cutter mixer with capacity of 150l for medium size production of confectionery, chocolate, ice cream, ready meals, cheese, cream smoothie, vegetable puree.

For more information, send us a request.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 150l

The conical bottom mixer with a 400-liter capacity is designed for efficient mixing and smooth product discharge. Its conical shape directs contents toward the lower outlet, making it ideal for processing thicker or denser materials in an atmospheric-pressure environment.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 400l

- Voltage: 380-400V

The price is set for the basic version of the vacuum evaporation unit with basic controls (mixer motor switch) and without additional options. The control unit is customized based on individual customer requirements. The pump is also selected separately depending on the product.

A compact vacuum evaporation unit that allows you to concentrate solutions, mixtures, and various products by evaporating the solvent. A modular version based on the basic version of the 110/100 vacuum reactor.

- Gravity mixing - 25% more efficient

- Reinforced agitator design with no blind spots

- Bottom ball valve with no dead zones

- Condensation and secondary vapor removal system

- Easy to disassemble mixing device

- Large heat exchange area

- Ability to measure and monitor condensate volume (optional)

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

- Working volume: 50-80l

- Condensing capacity, l/h: 45-55

- Steam consumption, kg/h: up to 150

The industrial mixing and homogenizing equipment is well-suited for small and medium-sized production enterprises engaged in the processing of food, cosmetics, and various chemicals.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 300 l

This is a 400 l capacity heating boiler, we offer different capacity commercial cooking boilers.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 25

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 400l

- Voltage: 380-400V

Used in chemical, construction, cosmetic or food industries.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 85

- Volume: 50l

- Voltage: 380-400V

The NORMIT drum mixers are designed for thorough mixing for products such as combined feed for animals, infant formulas, baby food, food concentrates and additives, sports supplements and nutrients, coffee, tea, pharmaceuticals and chemical products.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 50l/ 100l/ 150l/ 200l/ 500l

Highly efficient production of a high viscosity pharmaceutical and cosmetic products.

- Material: Stainless steel

- Principle of operation: Batch mode

- Geometric volume: 500 l/ 800 l

Mixers are carefully designed, constructed and tested to handle a variety of industrial applications that require mixing, dispersive mixing, distributive mixing and more.

- Material: Stainless steel

- Country of origin: Slovakia

- Voltage: 380-400V

- Geometric volume: 500 l

The coating machine is designed for uniform application, impregnation of oil and fat mixture, dyes and flavors, enzymes, vitamins and other additives, various products with a high level of hygiene.

- Material: Stainless steel

- Engine power, kW: 2,2

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 281 kg

- Volume: 500l

Running of various production processes such as cutting, mixing, crushing, refining and emulsifying different types of product in a single unit.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 359 kg

- Volume: 150l

A detachable lid with an automatic food stirrer for stainless steel 40 cm pots, suitable for volumes of 50 and 100 liters. An automatic stirrer allows you to mix and stir various products, including during thermal processing. The type of mixing device can be additionally selected depending on the required process.

- Professional industrial single-phase motor for 220-230 Volts

- The control is located directly on the motor housing or on the drive cable

- Easy and simple installation and fixation of the lid on the pan

- Suitable for standard 40 cm pots with a capacity of 50 or 100 liters

- The lid and stirrer are made entirely out of stainless steel

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Principle of operation: Batch mode

- Voltage: 220-230V

The Mak Mix tilting mixer is designed for preparing liquid and semi-liquid doughs. It's suitable for mixing dough for waffles, pancakes, cakes, and other baked goods.

- Made entirely out of stainless steel

- Features a tilting system with three working positions (up to 110┬░) for gravity mixing and quick emptying of the mixing bowl

- Frame mixer with a professional industrial motor

- Reinforced high-speed mixer for intensive mixing and kneading

- Safety switch on the top housing for safe operation: the mixer is switched off when the lid is opened

- Simple and easy to clean; the lid and mixer can be quickly and easily removed for cleaning

- Material: Stainless steel

- Engine power, kW: 0,37/ 0,55

- Volume: 50l/ 100l

- Voltage: 220-230V

- Stirrer speed, rpm: 35

A universal homogenizing module for mayonnaise production. The special compact atmospheric unit with a bottom homogenizer and a circulation system allows to create stable fat emulsion in just a few minutes!

- Compact design

- No dead zones and corners due to the conical shape of the unit

- Powerful bottom inline homogenizer with circulation

- Hygienic design

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

- Total power, kW: 9

The twinscrew mixer with two horizontal shafts is designed for intensive mixing and kneading dough as well as chocolate, pralines and other similar products with medium or high viscosity.

- Material: Stainless steel

- Engine power, kW: 2,2

- Country of origin: Slovakia

- Weight: 281 kg

- Volume: 500l

Suitable for mixing a small amount of dough or meat as well as other thick mixtures.

- Material: Stainless steel

- Engine power, kW: 0,55

- Principle of operation: Batch mode

- Volume: 10l/ 20l