CARAMEL, TOFFEE MASS

Professional cooking boiler with a stirrer for particularly thick and viscous products. An excellent technical solution for the production of caramel, syrups and sugar paste for sugaring. The heating source is selected separately.

- The kettle can be used on all types of cooking surfaces, including induction

- The basic version has easily removable, self-aligning stainless steel scrapers

- High torque of the stirrer with 14-18 revolutions per minute

- Professional 3-phase industrial motor

- The stirrer is turned on independently using a remote control with IP66 protection, connected to the boiler using quick-release connectors

- The unit can be connected to a 220-230 volt network even with a 3-phase motor!

- Material: Stainless steel

- Engine power, kW: 0,25/ 0,37

- Volume: 20l/ 50l/ 100l/ 150l

- Voltage: 220-230V

- Diameter, mm: 400/ 500/ 600

The price is indicated without the control unit

The heat exchanger is designed for efficient and gentle heat treatment: heating and cooling liquid and pasty products, including those with a high viscosity, such as jam, chocolate, caramel, glazes, creams, marinades, baby food, honey, fish or meat stuffing and many similar products.

- Uniform thermal processing of thick and viscous products thanks to the supply of the coolant into the duplicator

- Efficient heat transfer due to especially shaped blades

- Continuous operation that does not allow the product to locally overheat or overcool

- Intensive heat transfer due to the internal mixing of the product with scrapers

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 250l/ 500l

- Voltage: 380-400V

- Heat transfer area, m┬▓: 2,7/ 5,4/

The 1000 L vacuum cooker is used for cooking, concentrating, and evaporating food products under reduced pressure, allowing gentle heat treatment, improved flavor retention, and precise control of moisture content.

For a price quote, send us a request.

- Heating: Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 1000l

- Dimensions, mm: 1385x1283x1892

Universal cooking kettle with a built-in mixer, used for cooking and stirring a variety of food products, cosmetic emulsions, creams and much more.

- Easily removable self-adjusting scrapers

- Lid opening sensor for safe stirrer maintenance

- Hygienic temperature sensor for the product

- Large diameter outlet valve

- Safe steam outlet on top of the boiler lid

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

A vacuum evaporator is a device used to evaporate liquids at lower temperatures by creating a vacuum environment, which reduces the boiling point of the liquid and enables efficient evaporation without thermal degradation of sensitive materials. Working volume up to, l: 1900 l.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: up to 1900 l

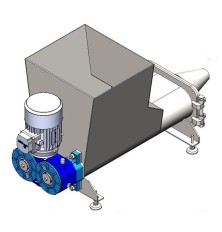

The Z-Sigma Arm paddle mixer is designed for intensive mixing, stirring, kneading and plasticizing products with high and very high viscosity, such as chewing gum base, stiff dough with low water content, toffee mass, soap base, adhesives.

- Double Z-shaped blade

- Very high shear force

- Minimum gap between z blades and the working container

- Independent electric drive for each blade

- Electric tilting for automatic unloading up to 180 degrees

- The mixer is made entirely out of food grade stainless steel AISI304

- Possibility to choose the side of tilting and unloading

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 70l/ 140/ 300l/ 460/ 700l/

- Voltage: 380-400V

Stainless steel jam cooking pot with agitator 50l and electric stove 5kW, ideal and affordable cooking solution.

- Heating: Electricity

- Material: Stainless steel

- Engine power, kW: 0,18/

- Heating power, kW: 5

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

The price is set for the basic version of the vacuum evaporation unit with basic controls (mixer motor switch) and without additional options. The control unit is customized based on individual customer requirements. The pump is also selected separately depending on the product.

A compact vacuum evaporation unit that allows you to concentrate solutions, mixtures, and various products by evaporating the solvent. A modular version based on the basic version of the 110/100 vacuum reactor.

- Gravity mixing - 25% more efficient

- Reinforced agitator design with no blind spots

- Bottom ball valve with no dead zones

- Condensation and secondary vapor removal system

- Easy to disassemble mixing device

- Large heat exchange area

- Ability to measure and monitor condensate volume (optional)

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

- Working volume: 50-80l

- Condensing capacity, l/h: 45-55

- Steam consumption, kg/h: up to 150

Cooking kettle for making syrups, caramel, sugaring paste as well as processing and producing various thick and viscous products. Often used for dissolving sugar and producing various saturated and supersaturated solutions.

- Built-in heating with thermal oil up to 150 degrees Celsius

- Anchor frame stirrer for rapid dissolution

- Conical bottom design of the working container without dead zones

- Heating: Electricity

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 200l/ 300l

- Total power, kW: 19

A modern cooking and mixing device with a wide range of applications in confectionery, bakeries, catering establishments.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 200l/ 300l/ 500l

The screw pump is used for transferring "un-pumpable" products. A great choice for those who work with hard to move liquids and need to move them as quickly as possible.

- Material: Stainless steel

- Voltage: 380-400V

A circulation-type vacuum evaporator refers to a combined version of an evaporator that also takes advantage of other types to improve evaporation efficiency particularly by reducing concentration time and when processing heat-sensitive products such as milk.

- The external circulation circuit with heating intensifies the cyclic evaporation process.

- The forced circulation system ensures a decrease in the risk of localized product overheating.

- The condenser enables a deep vacuum and maintains a low evaporation temperature.

- Utilizing a mixing device with a spray system facilitates product evaporation in a thin layer, mimicking a film-type evaporator.

- Heating: Steam

- Material: Stainless steel

- Operation mode: Semi-automatic

- Country of origin: Slovakia

- Total power, kW: 2,4

- Voltage: 380-400V

The vacuum evaporation unit is specially designed for thickening dense food products in industrial quantities. The evaporator can be used for the production of thick syrups, caramel masses, dense fruit masses, as well as for the production of pectin, or heat-stable fillings with a high productivity.

- High performance

- Rotary spraying system with a powerful electric drive

- Evaporation in a thin layer with a large heat transfer area

- Low investment installation costs

- Tangential entry for product swirling

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Voltage: 380-400V

The atmospheric tank with an inclined design is used for mixing, stirring, and dissolving various products. By supplying a thermal carrier to the unitŌĆÖs jacket (duplicator) from an external source, thermal processing such as heating or cooling can occur (i.e. heating or cooling from an external coolant source with an inlet pressure of up to 0.5 bar). These units are widely utilized in the food and cosmetic industries.

- Inclined design: 50% more efficient mixing

- Due to the inclination angle of the working tank, rapid and complete (100%) emptying is achieved.

- Efficient heat transfer through the heating/cooling jacket

- No dead zones during mixing!

- Modular system with a wide range of additional options

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Working volume: 100l/ 200l/ 300l/ 450l/ 600l/ 900l

Vertical shell and tube heat exchanger is designed to heat and cool such viscous/pasty products as sauces, mayonnaise, creams yogurts, jams, caramel, baby food, honey etc.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Shell-and-tube or tabular heat exchanger is designed to heat and cool viscous/pasty products such as sauces, mayonnaise, creams yogurts, jams, caramel, baby food, honey etc. Shell-and-tube heat exchangers are one of the most widely used units due to their robust design and a variety of options to suit different operating conditions.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

ACM mixing tank is intended for efficient cooling, heating, tempering and storing of mayonnaise, sour cream, chocolate, oil and similar products after their production.

- Material: Stainless steel

- Principle of operation: Batch mode

Model VMG S is an effective and reliable vacuum homogenizing unit designed to produce a wide range of liquid, pastry and viscous products with different requirements for the production conditions.

Filling machine is designed for pumping and filling high viscosity liquids, such as jams, confiture, sauces, dressings, syrups, and like products.

- Productivity: 200ŌĆō600 bottles per hour

- Material: Stainless steel

- Principle of operation: Continuous mode

A vacuum cooker is used in the food processing industry to cook ingredients under reduced pressure, typically in a vacuum environment. This method allows for precise temperature control and faster cooking times while preserving the quality and flavor of the ingredients.

We offer different vacuum cookers.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 2500 l

A Vacuum cooker is a versatile device used in culinary settings to cook food under vacuum conditions, enhancing flavors and textures while also reducing cooking times.

We offer various different cookers.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 380-400V

Twin-screw extruder is designed for effective extruding, homogenization, pumping over of plastic masses (butter, margarine, honey, curd products, confectionery mixtures), and forming it into bars and rolls.

- Productivity: 400 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Weight: 115 kg

Specialized vacuum cooking kettle for sweet masses, ideal for commercial applications and medium to large scale food production.

For a price quote, send us a request.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 200l

- Dimensions, mm: 2055x1800x1980

It is ideal for cooking jams, marmalades, syrups, sauces, creams and other products.

Price depends on the chosen option.┬Ā

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 300l

- Geometric volume: 350 l

The Atmospheric Evaporating Pan efficiently concentrates liquids by evaporating them on a large surface area, while also being suitable for various cooking methods including braising, cooking, and roasting.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

An evaporator concentrator-crystallizer is a multifunctional unit that concentrates liquids by evaporating water and inducing crystallization for the production of concentrated solutions or crystalline products.

- Material: Stainless steel

- Working volume: up to 6000 L

- Geometric volume: 6500 l

An evaporating unit is utilized to remove moisture from sweet substances through heating, transforming them into concentrated syrups or solutions.

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Voltage: 380-400V

- Geometric volume: 200 l

This semi-automatic filling machine is used for filling honey as well as other products. We offer many different kinds of filling machines for different applications.

- Material: Stainless steel

- Operation mode: Semi-automatic

A cooking kettle and a vacuum mixer for periodic deaeration of products such as mayonnaise, ketchup, various sauces, creams, gels and pastes. It is one of the modifications of a vacuum reactor and a vacuum evaporator. The presence of a vacuum system allows you to create a vacuum after the cooking process and perform vacuuming (deaeration) to remove air bubbles with potential contaminants and obtain a product with a denser structure. Thanks to vacuuming, the product has an extended shelf life, since pathogens and microbes contained within are removed together with the air.

- Inclined design with gravity mixing, which is 30% more efficient than usual

- 100% emptying of the product after processing due to the bottom valve

- Easy to disassemble removable mixing device

- Possibility of connecting it to a CIP station for cleaning and washing

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l

- Total power, kW: 0,12

- Max vacuum: -0,8 Bar