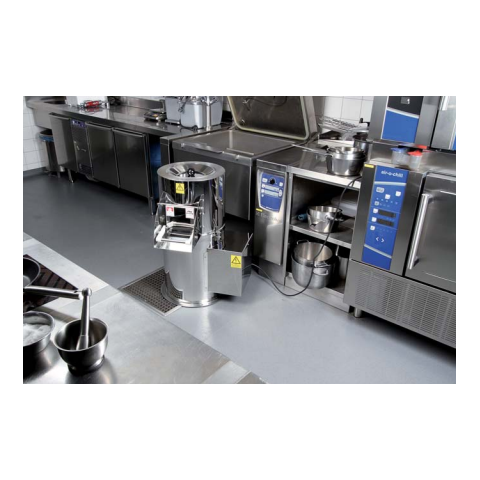

Potato Peeler

Potato and root vegetable peelers are manufactured in all-stainless steel casing. The device is directly ready for use (no installation required), it is supplied for a 3x400 V power supply.

The root vegetable peelers are supplied with a capacity of 100 to 450 kg of root vegetables and potatoes. Some clients also use this equipment for onions.

The product, which is placed in the machine, together with the stream of water is peeled on the corundum-coated walls and bottom of the drum. A stainless steel peel and starch separator can be purchased for the device. When using a separator, potato skin are fully biodegradable and can be composted, thus do not destroy the environment.

New potatoes are cleaned in about 1 minute, old ones with a thick skin in an average of 3 minutes.

New potatoes are cleaned in about 1 minute, old ones with a thick skin in an average of 3 minutes.

The peeling machines are equipped with modern 350-1100 W electric motors with IP 54 protection. To connect and power up the device, a source of voltage 3x400V, a water supply through a half-col hose and a waste outlet into the sewer is sufficient - the outlet channel of the device should point to the slope of the floor connected to the sewerage system.

Technical features

| 6 | 12 | 20 | 40 | |

| Voltage | 400 V | 400 V | 400 V | 400 V |

| Power | 350 W | 550 W | 750W | 1100 W |

| Dimensions (WxDxH) | 670x550x750 | 700x700x950 | 800x750x950 | 780x880x1000 |

| Product load, kg | 6 | 12 | 20 | 40 |

| Capacity, kg / h | 100 | 200 | 300 | 450 |

| Water consumption l / kg | 2,5 | 2.5 | 2.5 | 2.5 |

| Time for processing | 1,5-3 | 1,5-3 | 1,5-3 | 1,5-3 |

| Working cycle | 6 | 6 | 6 | 6 |

| Weight, kg | 51 | 62 | 72 | 85 |

- Engine power, kW: 0,35/ 0,55/ 0,75/ 1,1

- Country of origin: EU

- Voltage: 380-400V