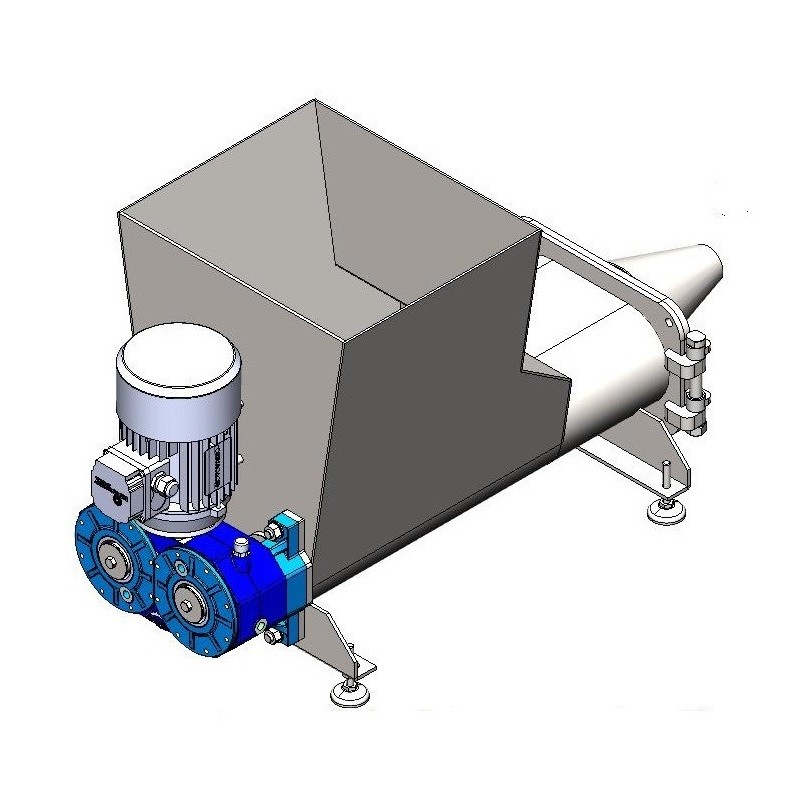

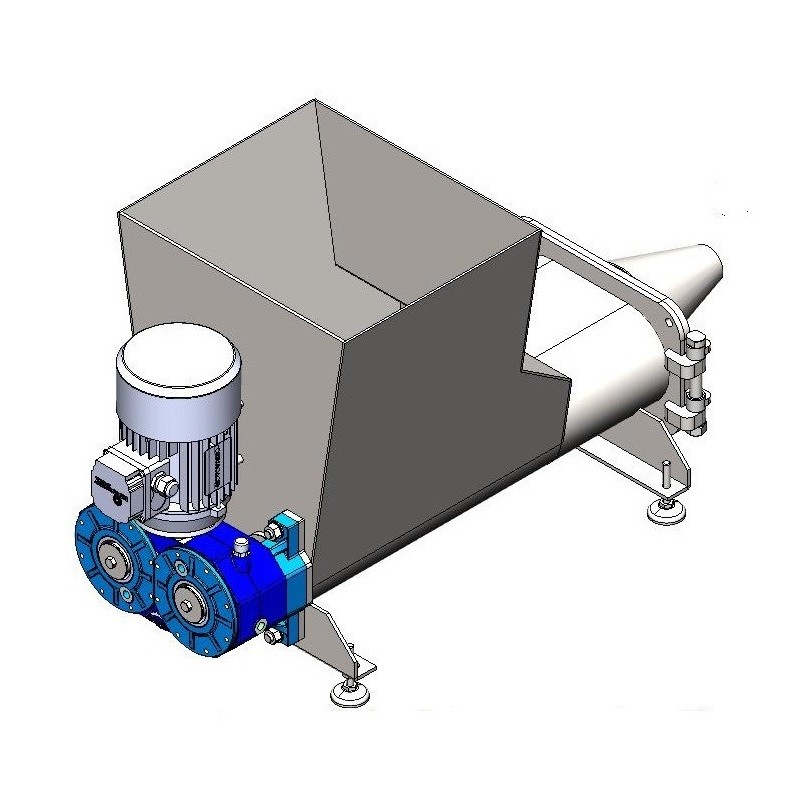

Screw feeding pump for viscous products

The screw pump is used for transferring "un-pumpable" products. A great choice for those who work with hard to move liquids and need to move them as quickly as possible.

The screw unit is mainly used for pumping product with medium to high viscosity. It enables to transfer of product with minimum damage or rise in product temperature.

This type of pump uses screws that intermesh to material and move them in a system. Less commonly used is the single screw pump, which uses only one screw and has more limited capabilities.┬Ā

Suitable for

- Butter or margarine

- Cereal bars

- Mashed potatoes

- Icing

- Chocolate

- Cream cheese

- Yogurt

Benefits

- Easy to disassemble

- Gentle handling ensures the product is not overworked

- Ability to provide high flow rates even in viscous liquids

- Material: Stainless steel

- Voltage: 380-400V

The single-stage vacuum pumps are versatile, offering a wide range of applications when it comes to transporting liquids due to their simplicity, reliability, and robustness. The device operates with minimal vibrations, and its noise levels do not exceed the prescribed standards. Additionally, it ensures oil-free operation.

Elliptical rotor pump (three power range models available).

- Material: Stainless steel

- Engine power, kW: 1,8/ 4/ 5,5

- Principle of operation: Continuous mode

This pump is a monoblock single-stage liquid ring vacuum pump suitable for low, medium, and high vacuum applications. It is an economical pump with exceptional performance and reliability.

- Productivity: 52 m3/h

- Principle of operation: Continuous mode

The circulation pump for the heating system is a mandatory component for the operation of a flow-through heating system used for heating the water serving as a heat transfer medium inside the duplicator of industrial cooking boilers, mixers, reactors, and vacuum evaporators in food production. It is selected based on the required parameters of the heating system (volume). Our specialists will be happy to assist you in selecting the appropriate pump if you provide the technical specification requirements. This pump is an essential additional component for the flow-through water heater┬Āup to 110┬░C.

- It can be used to circulate water at temperatures up to 110┬░ C

- High efficiency with low power consumption

- Also suitable for central heating systems, heated floors and even for solar systems

- Small connections allow the use of flexible pipes with a smaller diameter

- Type of the equipment: Optional equipment

Electric continuous flow heaters in different designs and performance parameters.

- Heating: Electricity

- Material: Stainless steel

- Country of origin: Slovakia

- Type of pump: sealless pump

One of advantages of this glandless pump is very high durability and efficiency in operation in very demanding conditions. We offer glandless pump with different power variations.

- Principle of operation: Continuous mode

Designed for pumping hot thermal oil in frying circulation and filtration systems, for oil loading and unloading, in "hot" continuous oil filtration systems with a maximum temperature of up to 200 degrees.

- Material: Stainless steel

- Engine power, kW: 0,55

- Country of origin: Slovakia

The high-performance screw pump is used for pumping both thick and viscous food products, as well as various masses containing pieces or solid inclusions such as in the cosmetics, cosmetology, and other industries.

- High performance

- All parts in contact with the product are made out of AISI304

- Does not damage products containing solid pieces

- Additional options: by-pass

- Material: Stainless steel

- Engine power, kW: 1,1/ 1,5 / 3

- Principle of operation: Continuous mode

The fruit mash pump is designed for efficiently transporting mashed fruits from a crusher to a press for extracting juice.

- Productivity: 6000 kg/h

- Material: Stainless steel

- Engine power, kW: 1,85

- Voltage: 380-400V

The portable vertical pump is designed for pumping fluent or viscous liquids in the range from 1-2300 m2/s at a temperature of around 25┬░C. The pump cannot be used in potentially explosive atmospheres.

- Material: Stainless steel

- Engine power, kW: 0,25

- Voltage: 380-400V

We offer different types of pumps for different processes.

- Engine power, kW: 0,37

- Dimensions, mm: 230x190x120

Vane pumps are used for pumping high viscosity products such as syrups, honey, mayonnaise, sauces, cream and many other products.

- Material: Stainless steel

- Engine power, kW: 2,2

- Type of pump: rotary vane

Stainless steel low-speed rotary pumps with flexible impeller; particularly suitable for transfer of delicate, fragile and viscous fluids, also with solid parts in suspension.

- Principle of operation: Continuous mode

The lobe rotary pumps are designed for pumping both liquid and thick products. We offer┬Ālobe pumps in 2 versions with┬Ā1.5 kW is a standard for milk, cream and similar products,┬Āand 3 kW is for dense low-flow products such as honey, pastes, cottage cheese etc.┬Ā

- Engine power, kW: 1,5 / 3

Progressive cavity pumps are used to transfer low and high viscosity products as well as products containing soft particles. They are available in three sizes.

- Material: Stainless steel

- Engine power, kW: 3/ 4

We offer a wide variety of different pumps for all kinds of liquids, semi-liquid products in various applications.

- Principle of operation: Continuous mode