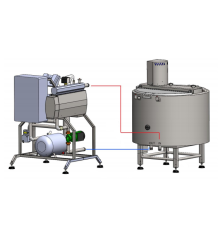

Vacuum dryer for honey 50 - 150 kg

A vacuum honey dryer is used to dehydrate (remove moisture from) honey at sub-atmospheric pressure.

- This highly efficient and innovative vacuum drying process guarantees honey drying rates exceeding 1% per hour!

- The vacuum dryer allows for quick and gentle drying of honey at temperatures up to 39┬░C without increasing hydroxymethylfurfural (HMF) levels.

- Any heat source (hot water, steam) can be used to supply thermal energy to the dryer's jacket.

- The specially designed mixing device enhances heat transfer within the product, improving its thermal efficiency and significantly reducing drying energy costs.

The vacuum honey dryer is suitable for both drying and creaming honey, as it can accommodate both hot and cold coolants in the duplicator of the installation. This versatility allows the vacuum dryer to perform multiple functions for honey production. This model is popular for its capacity, making it suitable for use in both apiaries and small industrial operations.

A vacuum honey dryer, or honey dehydrator, is essential for drying honey that may be more humid in cold or rainy seasons when bees struggle with natural fermentation and drying in the hive. Honey dryers are also used to diversify honey varieties, as they allow for earlier extraction depending on the flowering seasons of honey plants.

Advantages

- Fast and efficient drying: The vacuum drying process prevents the increase of hydroxymethylfurfural, a compound that rises when honey is heated above 40┬░C. Typically, high temperatures are required for fast and efficient water evaporation, however the vacuum system lowers the boiling point, reducing the heating temperature of honey and preventing it from reaching levels that would increase HMF formation.

- Active heat transfer: The circulating coolant throughout the jacket's height provides consistent, indirect heating, reducing the risk of localized overheating.

- Special mixing device: This device lifts the product in a spiral, creating circulation from the walls to the center, which enhances heat transfer and mixing during the drying process.

- Special bottom valve: Included in the basic version, this valve ensures complete discharge of the product, leaving no blind spots where honey could remain, thus minimizing contamination or mixing of different honey types during processing.

- High productivity: The vacuum drying process achieves a honey drying speed of over 1% per hour.

Basic Version

The basic version includes a vacuum reactor on a supporting structure with a fully opening top hatch, a jacket for the coolant (covering the bottom and walls of the entire working container), thermal insulation, an external decorative casing made out of polished stainless steel, equipped with a special mixing device with a professional industrial motor, a bottom valve, a secondary steam removal and condensation system, and a vacuum generator (ejector for compressed air). For optimal operation, the vacuum system requires a compressed air source with a pressure of 6-10 bar and a source of ice water for the condenser with a temperature of 7-12┬░C.

Options

- Air compressor

- Hot water source - electric flow heater

- Ice water station

- Cooling unit - chiller

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Max vacuum: -0,8 Bar

You might also like

The new line of NDJ refrigeration units is suitable as a cooling source for industrial applications operating with a closed coolant circuit. Efficient and reliable flow cooling of liquids

- Principle of operation: Continuous mode

- Country of origin: EU

Electric heating panel with three different power possibilities: 12, 24 and 48 KW ŌĆō excellent product manufactured by people who perfectly know the secret of product storage, maintenance and processing.

- Heating power, kW: 12/ 24/ 48

- Country of origin: EU

The oil-free four-cylinder piston compressor is the ideal solution for those who value both performance and silence.

- Equipped with two twin-piston units with separate engines

- Four air filters

- Mechanical pressure switch

- Quiet operation (at least 25% quieter than traditional compressors)

- Carrying handle and mobile wheel support

- Principle of operation: Continuous mode

- Total power, kW: 1,5

- Voltage: 220-230V

The price is set for the basic version, without additional options.

The industrial infrared dryer is suitable for drying a wide range of products: nuts, apples, plums, strawberries, raspberries, blueberries, mushrooms, carrots, onions, garlic, herbs, meat, figs, bananas, marshmallows. If additional options are selected, it can also be used for curing and drying whole meat and fish.

- Compact installation

- Fast and efficient drying

- Possibility of selecting individual settings for drying

- Made entirely out of stainless steel

- The interior surface of the cabinet has a mirror coating

- Quiet operation of the installation

- Low energy consumption per drying cycle

- Heating: Electricity

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 7l/ 10l/ 14l

- Total power, kW: 10/ 15/ 20

- Area, m┬▓: 3,5/ 5,2/ 6,9

- Number of shelves: 10/ 15/ 20

A circulation-type vacuum evaporator refers to a combined version of an evaporator that also takes advantage of other types to improve evaporation efficiency particularly by reducing concentration time and when processing heat-sensitive products such as milk.

- The external circulation circuit with heating intensifies the cyclic evaporation process.

- The forced circulation system ensures a decrease in the risk of localized product overheating.

- The condenser enables a deep vacuum and maintains a low evaporation temperature.

- Utilizing a mixing device with a spray system facilitates product evaporation in a thin layer, mimicking a film-type evaporator.

- Heating: Steam

- Material: Stainless steel

- Operation mode: Semi-automatic

- Country of origin: Slovakia

- Total power, kW: 2,4

- Voltage: 380-400V

The peculiarity of this unit is the combination of several functions: homogenization and drying of honey. The vertical vacuum dryer allows you to dry honey weighing up to 3300 kg in a short time while preserving its useful properties, color, taste, and organoleptic qualities. The vacuum honey dryer has a number of significant advantages over classic atmospheric honey dryers due to the reduction of processing time and the preservation of its beneficial properties, which is achieved by drying at a lower temperature.

- The drying process occurs much faster due to the evaporation of moisture under vacuum.

- High degree of homogenization of honey due to the operation of a special mixing device.

- The narrow vertical design does not require large production areas while boasting high productivity.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The price is set for the model with an area of 7 m┬▓

Compact condensate dryer, heat pump powered dehydrator for drying vegetables, fruits, berries, mushrooms, legumes and grains.

- Energy saving, low consumption model (consumption up to 0.9 kW/h)

- Possibility of increasing the drying area in this model up to 14 m┬▓ (optional)

- Intensive drying, each section is equipped with a heat pump

- Automatic drying system control

- Delicate drying at low temperatures

- Preservation of most nutrients and the products natural color

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Total power, kW: 0,9

- Voltage: 220-230V

- Area, m┬▓: 7

- Number of shelves: 22

Designed for "cold" vacuum drying of products sensitive to high temperatures, also suitable for liquid and viscous products.

Model VMG S is an effective and reliable vacuum homogenizing unit designed to produce a wide range of liquid, pastry and viscous products with different requirements for the production conditions.

This convective honey dryer is used for drying and mixing honey, it is a high-performance solution for thoroughly mixing honey while simultaneously removing excess moisture.

- Material: Stainless steel

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Voltage: 230 V/ 380-400V

A vacuum deaerator is extensively used in the food industry to remove gases from products that may retain some bubbles post-processing. Additionally, a flow deaerator is utilized to minimize foaming in products, ensuring a denser structure, especially prior to packaging. Vacuum deaerators play a crucial role in eliminating specific odors from the products, such as in the production of juices, purees, and herbal drinks. This process significantly contributes to enhancing the overall quality and taste of the final product.

- Enhances product quality, structure, and shape

- Prevents oxidation by removing gases

- Preserves organoleptic properties and extends the shelf life

- Suitable for thick and viscous products

- The flow principle allows for the installation of this equipment in existing production lines

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

A tilting frying pan with a stirrer and indirect electric heating using thermal oil is designed for processing small batches of raw materials, making it suitable for stewing and frying various foods. The automatic stirring feature enhances the preparation of vegetables, fish, meat, and sauces.

- Compact model

- Uniform heating due to the thermal oil

- Simple controls

- Electric tilt of the working bowl

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 18

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 140l

- Total power, kW: 19

This compact nuts and seeds roaster is ideal for efficiently and evenly processing nuts and seeds to perfection.

- Productivity: 5-15 kg

- Material: Stainless steel

- Principle of operation: Batch mode

Multifunctional vacuum unit MINI5 - is ideal for cooking, drying, concentrating, mixing and much more. Suitable for laboratories and small-scale production.

- Processing heat-sensitive products at lower temperatures

- Ideal for making creamed honey

- Possibility of vacuum drying honey

- Material: Stainless steel

- Engine power, kW: 0,12

- Country of origin: Slovakia

- Volume: 5l

The vegetable spin dryer has been designed for drying leafy vegetables rapidly and efficiently, both raw and boiled, prepared in medium-large sized professional kitchens and in food industries.

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Batch mode

- Voltage: 220-230V

The high quality atmospheric 1500 kg condensate honey dryer is designed specifically for professional honey dehumidification.

Price depends on the chosen option.

- Material: Stainless steel

- Working volume: 1000

- Dimensions, mm: 3600x1400x2000

This industrial hybrid drying cabinet combines two drying principles: heat pump (condensation) and convection (forced circulation of heated air). This dryer is designed for fast, efficient, energy-saving, and "cold" drying of vegetables, fruits, berries, mushrooms, legumes, herbs, meat, fish, and even liquid or semi-liquid products by replacing the shelves with standard GN 2/1 containers. The size of one shelf is 530 x 650 mm.

- Dual technology: condensation drying + hot air convection

- Energy-efficient with optimized consumption (approx. 0.9ŌĆō1.3 kWh depending on mode)

- Drying area expandable up to 14 m┬▓ (optional)

- Uniform drying thanks to forced air flow and controlled moisture removal

- Gentle operation at low temperatures for maximum preservation of nutrients and color

This multi layer belt dryer with integrated cooling system works as a dryer and cooler in one installation.

- Material: Stainless steel

- Principle of operation: Continuous mode

Working volume: 1000 l =┬ĀHoney dose: 1500 kg

Working volume: 2000 l =┬ĀHoney dose: 3000 kg

The price depends on the chosen option.┬Ā

- Productivity: do 3000 kg

- Material: Stainless steel

- Country of origin: Slovakia

- Working volume: 2000 l

- Geometric volume: 4000 l

- Dimensions, mm: 4300x2760x2450