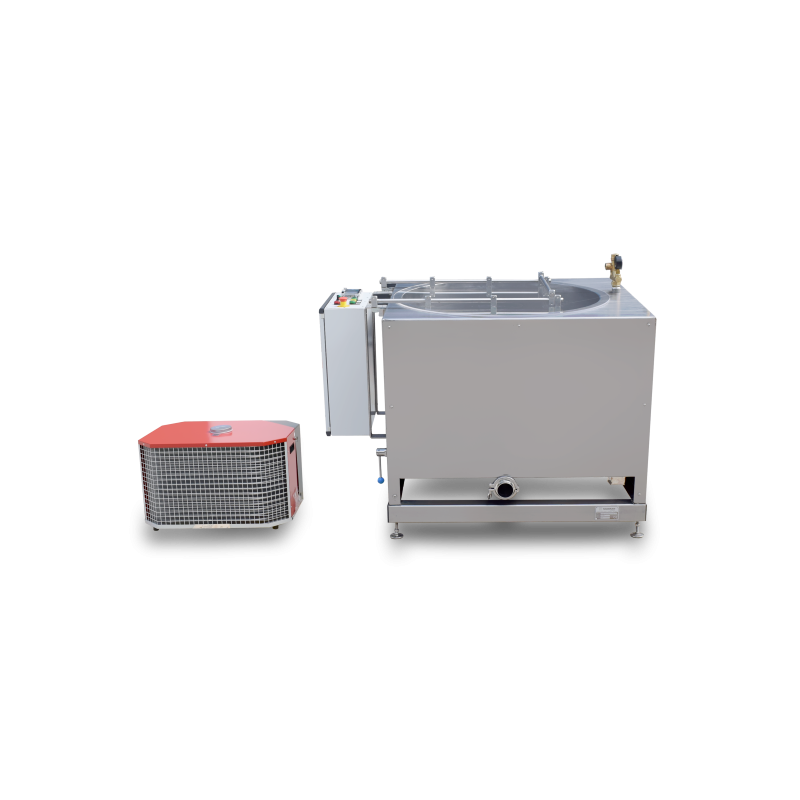

Honey creaming machine CH MEDIUM 400

Our company offers equipment for whisking honey with a new updated design with gravity mixing! A characteristic feature of the new series, which is 20-25% more efficient than conventional mixing! The inclined design also makes it easier to unload the product after processing, due to the centrifugal force and gravity!

This is a compact honey creaming unit with a casing where an atmospheric working chamber with a jacket for heating or cooling is built in, equipped with a special frame mixer with Teflon scrapers and gravitational mixing with an electric drive and a control panel.

The special shape of the "duplicator" is designed to prevent the transfer of blind spots during heat transfer between the coolant and the product.

The coolant is supplied to the "duplicator" (0.5 bar g). The mixing device can be quickly dismantled, which ensures easy and simple use. Special Teflon scrapers scrape the newly formed crystals from the walls of the device.

The cover is made out of transparent refractory material, which allows you to control and track the process.

The main advantage of the technique is creamy honey in 4 hours!

Cream honey production

Cream honey plant Normit CH-Medium belongs to a series of equipment for batch processing of honey, it is intended primarily for:

- decrystallization,

- recrystallization (decrease in crystal size),

- ācontrolled crystallizationā,

- improving its structure (homogeneity)

- melting honey crystals

Thus, the equipment can also be used to melt the residual crystals after the honey has been previously dissolved in a honey oven.

Translucent lid Allows you to see how the honey is being processed while the machine is running. You can react quickly in case it is required.

Drain honey easily

The CH honey creamer has been designed at an angle so that all the honey can flow off easily. This minimizes blind spots. All of the product will drain.

Specially designed agitator

The agitator cuts the honey and effectively transfers heat from the duplicator to the center of the honey. The stirrer can be quickly removed. Just take it, pull it towards you and hold it in your hands - for quick cleaning or to replace it with a second agitator.

Ergonomic Design:

The valves are on the right side, the actuator is on the left. They do not interfere with each other, which makes it easy to manipulate them.

Can be offered as additional options:

- closed heating system,

- heat generators,

- refrigeration units,

- Thermally insulated IBC containers.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia