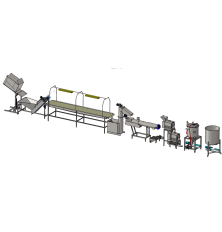

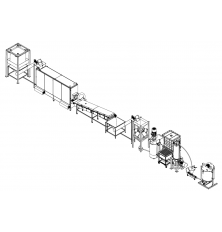

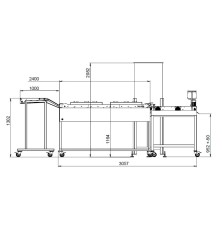

Honey processing equipment

We offer equipment for processes such as: honey dissolution, honey drying, honey homogenization, honey pasteurization, honey creaming and honey packaging. The necessary equipment is selected by the customer based on the required processing technology for their manufacturing process.

We provide a comprehensive range of equipment to facilitate every stage of industrial honey processing:

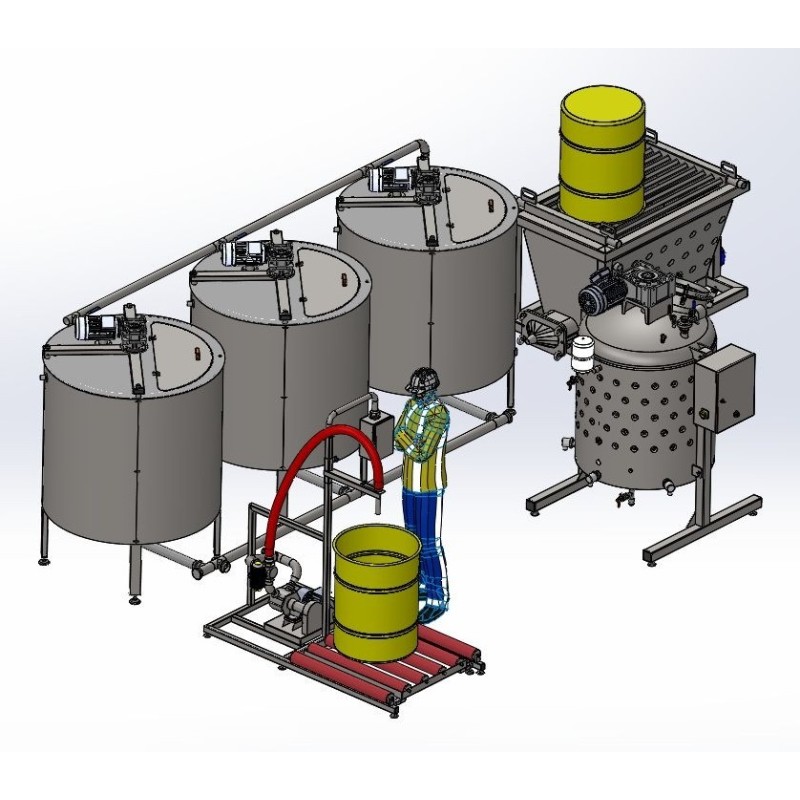

- Equipment for melting and feeding honey

At honey processing plants, honey is usually delivered in food-grade barrels of 200-220 liters. It can have a dense, crystallized structure. Therefore, for melting and feeding honey, a so-called turbomelter is used. This equipment features a specialized melting grid where barrels of honey are placed (depending on the model, 4 barrels of 200 liters each can be placed parallel in the 400/800 model).

The turbomelter is used for the periodic processing of honey, which includes:

- Pre-melting of large honey crystals and crystallized honey

- Mixing with heating via a "jacket" to improve its structure and homogeneity

- Feeding honey for further processing

A special feature of this equipment is, that it can handle honey of various degrees of crystallization.

It's recommended to use the turbo melter before filtration, drying, homogenization, creaming, or packaging honey.

The turbomelter is equipped with a special "melting grid" located at the top of the unit, where a heat carrier circulates. Honey on the grid heats up, changing its viscosity, and flows smoothly into the working tank of the turbomelter. Beneath the "melting grid," there is a special filtering mesh that prevents foreign particles from entering the product.

The working tank of the turbomelter is equipped with a heating/cooling "jacket" along the entire height of the sides and bottom of the unit. This design allows for uniform heating of honey during processing. Inside the working tank, there is a plasticizer/a screw. The honey inside the tank is heated and, with the help of the screw, is fed for further processing.

The installation can be equipped with two screws that rotate toward each other, effectively breaking down and mixing the honey between them, resulting in a homogeneous structure, which is then discharged from the unit. It can also be used as a feeder for loading honey into other processing units.

For the proper operation of the installation, an external source of hot water supply needs to be connected. This is not included in the standard package but can be ordered separately. It is not recommended to heat honey above 40 degrees Celsius!

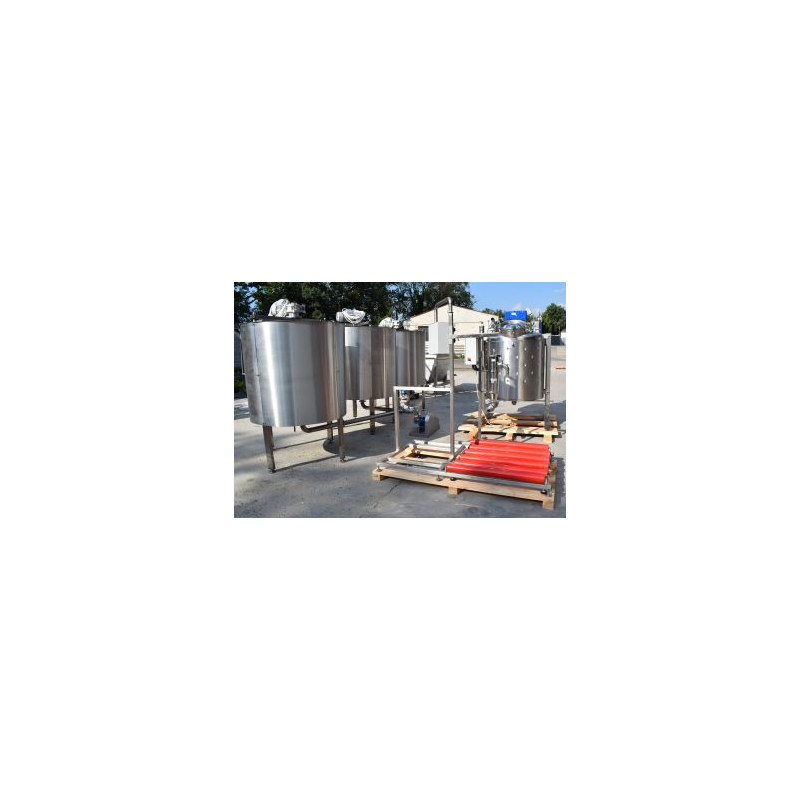

- Equipment for honey homogenization

Homogenization units for honey come in vertical or horizontal types, depending on the volume. Equipped with a mixing device with an electric drive‚ÄĒa screw of special design‚ÄĒvertical models lift and push honey from the bottom to the top, creating a "whirling fountain" in the center of the tank. Horizontal units, on the other hand, raise the honey above the working level with their blades/paddles and incorporate it into the main mass, propelling the product forward through reciprocating movements. Thanks to their unique structure, size, and the angle of the rotor screw, these units achieve a high level of homogenization, which also reduces the processing time.

Homogenization units are used for the periodic processing of honey, including:

- Enhancing the uniformity of the structure (creating smaller, uniformly sized honey crystals)

- Improving the organoleptic properties of the product, including retarding the growth of crystals

Honey homogenizers are equipped with a heating "jacket" with a heat carrier pressure of up to 0.5 Bar. Sources of heat carrier (hot water supply) can be ordered separately.

Some moisture evaporates during the homogenization process due to the heat applied, which helps in drying out the honey.

In industrial complexes, highly efficient vacuum honey dryers are used for drying honey, ensuring rapid drying in a short time. Vacuum honey dryers belong to the periodic vacuum-evaporation equipment for dehydrating honey. They are equipped with a heating "jacket" with a heat carrier pressure of up to 0.5 Bar, a screw of special design, a vacuum system, and a heat exchanger-condenser. This equipment allows for quick and damage-free drying of the product (at a product temperature of up to 39¬įC) through the vacuum system. The unique shape of the mixing device and the large heat transfer area of the "jacket" enable efficient heat exchange within the product, making the process more effective and significantly reducing energy consumption.

Water or steam from an external source can be used as the heat carrier.

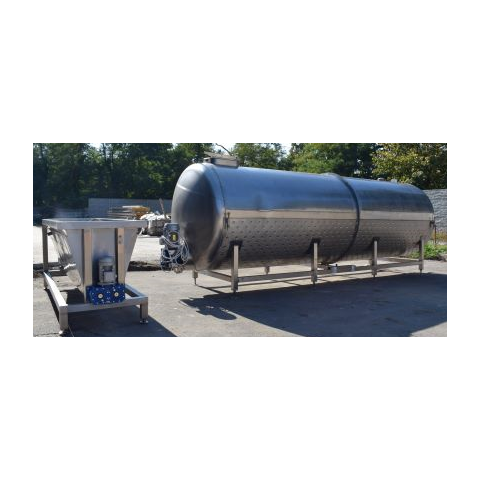

The intensity of evaporation also depends on the surface area of evaporation, the so-called mirror, which is why dryers are designed with an inclined design and, in the case of large volumes, a horizontal design.

*-During honey thermal treatment, it is crucial not to heat honey above 40¬įC. At higher temperatures, toxic substances, particularly hydroxymethylfurfural (HMF), are formed as intermediate products of sugar decomposition. Above 40 degrees Celsius, the amount of HMF increases rapidly, and heating honey above 60¬įC raises HMF content to dangerous levels for human health. HMF possesses carcinogenic properties and affects the central nervous system, contributing to the development of malignant tumors. The maximum allowable content of HMF in 1 kg of honey should not exceed 25 mg.

Advantages of vacuum honey drying:

- Low operational costs

- Large heat exchange area, including heated scrapers and shaft, ensuring maximum energy transfer

- Absence of "dead zones"

- The drying process occurs at a low temperature, guaranteeing the preservation of all beneficial properties of honey

- Easy cleaning and maintenance.

We also manufacture highly efficient condensation / condensate dryers for honey, which provide an economical solution due to low energy consumption based on the principle of a heat pump. Inside the horizontal unit is a mixing device - a system of disks that allows for drying honey in a thin layer. Dry air is introduced into the working chamber, directed straight at the disks with the product. The air gradually becomes moist as it evaporates from the product. The moist air then enters the heat pump, where excess moisture condenses and is expelled from the unit or collected in a condensate collection tank. This allows for monitoring and controlling the drying process.

Continuous mixing ensures even distribution of heat within the working tank and removal of moisture from the product. Scrapers located between the disks provide better product mixing and prevent the product from adhering to the walls.

Advantages of condensation honey dryers:

- Low energy consumption

- Efficient and fast drying in a thin layer

- High productivity

- Drying at "low" temperatures, suitable for processing heat-sensitive products.

- Equipment for honey pasteurization

For honey pasteurization, we offer continuous UTO units with subsequent cooling, with capacities ranging from 500 to 2000 kg/hour. These units are based on plate or shell-and-tube heat exchangers with a two-stage filtration system.

These units are used to halt carbohydrate fermentation and destroy osmophilic yeast, which are often present in immature or "wet" honey (18-20% moisture content). Matured honey with a moisture content of 17% usually contains very few microorganisms responsible for fermentation. There is only one guaranteed method to prevent subsequent honey fermentation, which is to heat it to a temperature of 75-80 degrees Celsius. Rapid heating followed by intensive cooling does not compromise the nutritional and healing properties of honey. It increases its shelf life by slowing down the crystallization process under proper subsequent storage conditions (airtight and protected from sunlight, at temperatures up to 20 degrees Celsius).

All pasteurizers are equipped with a special screw pump at the "inlet" for delivering honey to the heat exchangers.

Heating in the pasteurization zone is achieved by supplying a heat source to the heat exchanger. Depending on the type and model, the heating can be built-in or independent with adjustable power.

For subsequent cooling, a heat carrier with a temperature of 5-7 degrees Celsius from an external source of ice water station needs to be introduced into the cooling zone of the heat exchanger. This is not included in the standard package but can be ordered additionally as a refrigeration unit with an insulated IBC container and circulation pump. The cooling unit's power is chosen based on the heating system's capacity.

We offer both plate pasteurizers with recuperation and shell-and-tube models with varying capacities.

Advantages:

- Continuous operation and high productivity

- Large heat exchange area in the heating and cooling sections

- Intensive and even heat transfer due to the "wave breakers" system for turning the heat carrier

- Dual filtration system (coarse and fine) with the possibility to adjust the filter mesh size from 100 to 1000 microns

- Automatic operation system based on a PLC controller.

- Equipment for honey filtration

Depending on the equipment configuration, we offer various honey filtration systems, including single-stage and two-stage setups. Before processing honey, for instance, before homogenization, it's recommended to filter honey through a flow-through coarse filtration system, which captures impurities such as bits of wax, bee wings, and other foreign fragments. The filtration system includes stainless steel flow-through filters with a product pump (screw pump). For continuous operation or in case of heavy contamination, a bypass system can be installed for dual operation. If one filter becomes clogged, you can redirect the flow through the second filter (in parallel) without stopping the process and clean the cartridge of the first one. The filtration system is easily disassembled for cleaning; the stainless steel internal cartridge can be washed with hot running water.

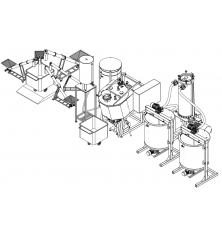

- Equipment for Honey Creaming

In large industrial complexes, after pasteurization, honey can undergo not only packaging but also partial creaming to produce a special type of honey known as creamed honey. Equipment for creamed honey production can be categorized into three main types:

- Atmospheric Creamers with Integrated/External Cooling System: Depending on the model's capacity, these creamers can come with an integrated cooling system or an external cooling system.

- Vacuum Creamers with External Cooling System: This system can be optionally equipped with various cooling capacities.

- Atmospheric Cutters for Creamed Honey Production: These devices are used for creating creamed honey.

These setups enable controlled honey crystallization (decrystallization and recrystallization) and improve the honey's structure, uniformity, and sensory properties. Creamed honey has a creamy, uniform structure and doesn't recrystallize, making it suitable for various uses. In some countries, the creaming process is also referred to as "honey pasting."

We offer all three types of setups, each with its own advantages. The choice depends on the desired final product. For example, an atmospheric cutter with a cooling jacket is suitable for producing creamed honey with added ingredients like fruit chunks. On the other hand, vacuum creaming setups are ideal for achieving a dense creamy structure and removing excess air bubbles.

Regardless of the type of setup, an external ice water source is needed for cooling. A refrigeration unit with a buffer tank and a forced circulation cooling loop is commonly used to maintain the water temperature between 5-7 degrees Celsius. This prevents the chiller from receiving water at temperatures higher than 23 degrees Celsius, which could lead to equipment failure.

The vacuum system in vacuum setups comes in different options:

- Ejector using compressed air (requires a constant supply of compressed air at 6-10 bar)

- Ejector using water (requires a pump to create the vacuum)

- Vacuum water-ring pump (requires a water circulation system for cooling)

Advantages:

- Creamed honey in 4 hours!*

- Gravitational mixing which is 25% more effective compared to traditional methods

- Convenient unloading due to the inclined setup design

- An automatic creaming program.

*- depending on honey type and quality, the maximum moisture content of honey before creaming should not exceed 17%.

- Equipment for Honey Packaging

We offer various honey packaging systems, ranging from small setups with pneumatic dosing for filling small containers to large-scale packaging in barrels using load cell stations. In industrial systems, dosing stations with load cells are often used. These dosing-fillers consist of a product pump, piping with valves, scales, and load cell sensors. The dosing process involves pumping the processed honey into packaging containers. The filling is regulated by load cells, allowing precise control of the fill weight (up to a maximum of 200 kg). When the desired weight is reached, the valve redirects the product back into a closed-loop system, where residual product circulates. The system allows setting and adjusting the dosing volume in kilograms. After reaching the set value, the product pump stops, allowing the operator to replace the filled container with an empty one for the next loading.

- Material: Stainless steel

- Type of the equipment: Part of a production line

- Country of origin: Slovakia