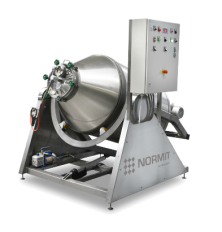

Diffuser - Vacuum coater DifuVac

Vacuum diffusion - the process in which the air inside the product is removed by vacuum and the released pores are filled with flavor, vitamins or other ingredients.

┬Ā

Vacuum coating or "diffusion" is a physical process in which vacuum removed gas from the product pores, then the product is mixed with the liquid under vacuum conditions, then a vacuum is released which pull liquid deep into the product pores.

The vacuum coating process also helps to maintain the taste and color of the product and to maintain the effect of functional ingredients such as vitamins, minerals, ameliorators, yeast and enzymes.

Time is money. Don't marinate for 8 hours, only 1 hour. Thus, in a diffuser, you will work 8 times faster than if the product was soaked in marinade in an open container.

The vacuum coater is ideal for:

- beans

- plump and other fruit

- marinating meat

- sunflower, other seeds

- many other products Intended for use in the food industry, chemical, pharmaceutical and many others.

Advantages over conventional seasoning

- More accurate dosing and better flavor distribution

- A much simpler and cleaner process

- Extends product shelf life

- Reducing waste and product loss

Types of liquid ingredients

- Fat

- Oils

- Omega 3

- Flavors

- Vitamins

- Antioxidants

- Pharmaceutical products┬Ā

- Pigments (fish feed)

DifuVac ST-300 - refers to the equipment of periodic action:

- on saturation with aromatic, vitamin impregnation of various products;

- due to the removal of air from the working tank and the product in it, absorption / filling with various formulations (additives).

The installation package includes: working tank, basket for the product, pump, vacuum system, control system. Processing time depends on the productŌĆÖs properties (mainly air content)

DifuVac ST vacuum diffuser is intended for performing diffusion treatment of a wide range of products, both low- and high-density. This vacuum liquid coater contains of sealed stationary working vessel, perforated basket, vacuum generation and maintaining system, process control system.

When dipping the product into marinades, syrups, salt liquids, spices dissolved in water or oil, and other liquids that flavor the product, it will soak the liquid over a long period of time and get the desired taste from the liquid. But it takes a long time. Difuvac will take care of it, but in a very short time.

Features:

- Vacuum container 350 liters

- Basket - 200 liters capacity - opening from above, also from below for rapid emptying

- Electrical cabinet

- Vacuum meter

- Display window

- Pump

- Vacuum suction nozzle

Also we have a rotating┬Āvacuum coater

- Material: Stainless steel

- Country of origin: Slovakia

- Geometric volume: 350 l/ 700 l