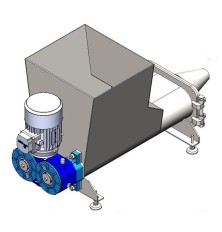

Dosing system with a reservoir MV 100

Dosing tank for filling and measuring oil designed as an oil reservoir with the ability to adjust the required volume.

This device is equipped with a control unit, a level sensor and an electrical socket for connecting any pump (at the maximum electric range of the electrical equipment of the vessel).

HOW IT WORKS

Connect the pump to the vesselŌĆÖs inlet and plug it into an electrical outlet on the electrical cabinet under the container. After pushing the button, the pump switches on and starts filling the container with liquid. It fills it until the level sensor detects the set liquid level (this will ensure the set volume) and shuts off the power to the electrical outlet, thereby interrupting the pump operation. Subsequently, the attendant moves the feed from the vessel outlet to the desired machine and, after opening the manual valve, the liquid flows through the gravity to the destination.

At the request of the customer, a load bar, which shows the current oil level to the operator, can also be provided.

After emptying the container, it is necessary to wash the container, close the manual valve and, after pressing the button on the electrical cabinet, pump the tank again to the required volume.

Technical data:

|

Material |

AISI 304 |

|

Geometric volume (open tank) up to, l |

100 |

|

Geometric volume (closed tank) up to, l |

100 |

|

Working volume up to, l |

80 |

|

Length, mm |

1250 |

|

Width, mm |

450 |

|

Height, mm |

1800 |

|

Weight, kg |

60 |

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l

- Working volume: 80 l

Semi automatic packaging machine for filling and capping jars.

- Material: Stainless steel

We offer different types of sausage filling and stuffing machines. This version is a simple tabletop filling device with hydraulic filling.

- Material: Stainless steel

- Engine power, kW: 0,18/

- Country of origin: EU

- Weight: 46

- Volume: 15 l

- Dimensions, mm: 320 x400x1260

The manual bottle filler is designed to fill liquids in glass bottles.┬Ā

- Productivity: 650 psc/h

- Material: Stainless steel

- Operation mode: Manual

A range of pneumatic vertical filling machines for dosing liquids with viscosity is similar to water.

- Type of the equipment: Individual machine

Hydraulic sausage filling machine is the ideal equipment to fill sausage of various specifications and is suitable for filling in different kinds of casings.

We offer different meat processing machines.

- Material: Stainless steel

- Engine power, kW: 0,37

- Weight: 92 / 135

- Voltage: 380-400V

The screw pump is used for transferring "un-pumpable" products. A great choice for those who work with hard to move liquids and need to move them as quickly as possible.

- Material: Stainless steel

- Voltage: 380-400V

Compact digital filling machine for accurate dosing of viscous liquids such as honey, pastes, sauces, and oils. Designed with food-grade materials, easy-to-clean components, and precise digital control, it is ideal for small production, workshops, and laboratories.

- Operation mode: Semi-automatic

A filler is a device designed for dosing and pumping honey. It guarantees comfortable and professional honey processing.

- Material: Stainless steel

- Engine power, kW: 0,18

- Voltage: 220-230V

The pneumatic piston filler for pastes and liquids is a semi-automatic dispenser designed for dosing various liquids with a low, medium or high viscosity.

- Tabletop compact model

- Includes a built-in 26 l conical storage tank

- A wide dosing range from 300-2500 ml

- Can also be used for products with a high degree of viscosity

- High dosing speed

- Possibility of working in manual or automatic mode

- Material: Stainless steel

- Principle of operation: Continuous mode

- Volume: 300-2500 ml

- Voltage: 220-230V

A filling machine for stuffing meat to make sausages. We offer many different dosing machines for different applications.

- Material: Stainless steel

- Operation mode: Manual

- Weight: 27/ 28/ 30

- Dimensions, mm: 710x280x390 / 790x280x390 / 820x280x390 /

The piston-operated pneumatic liquid dispenser is a semi-automatic filler used for dispensing various low viscosity liquids ranging from 10 to 100 ml in volume.

- Compact tabletop installation

- Simple control with two operating modes: manual and semi-automatic

- Suitable for liquid products with low viscosity (from water to oil)

- Optional compressed air compressor available

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Continuous mode

- Voltage: 220-230V

Semi-automatic dosing machine, designed for filling and capping different spouted pouches with various liquids.

- Material: Stainless steel

- Operation mode: Semi-automatic

We sell many different filling machines for different products.

- Material: Stainless steel

- Country of origin: EU

The piston filler is designed for dosing different types of liquid products in the food, chemical, pharmaceutical and cosmetic industries.

- Material: Stainless steel

- Operation mode: Manual

- Type of the equipment: Individual machine

The honey dosing machine is a precise filling machine with a gear pump, it is easy to use and is suitable for filling honey as well as a large number of other different liquids - ranging from thinner ones such as drinking yogurt, to high-viscosity products such as mustard.

- Fast operation

- Easy to use

- Easy to clean

- Accuracy

- Compact design

- Productivity: 200 l