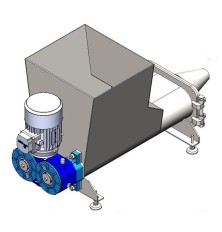

A professional filling and capping machine

Maximum production is about 1000 bph depending on the volume, the product features and the pouches features.

The machine is suitable for filling and capping flexible pouches (with an already existing spout) with liquid / semi-liquid products by a volumetric piston filler with a 5-260 ml dosing range (optional 20-680 ml) and closing the same with 1 size of plastic screw cap. All the parts in contact with the product are manufactured with AISI 316 L stainless steel and PTFE and FKM gaskets. The filling and capping stations stand in a 600 x 600 mm cabin with front and back access doors. The machine features an automatic vibrating base cap sorter and feeder. The cap tightening is performed by a pneumatic motor or by a hysteresis magnetic clutch, depending on the requirements.

TECHNICAL FEATURES:Â

- The machine main frame is stainless steel AISI 304 made and stands on adjustable height feet.

- All supports and shaft on the machine, that could get in contact with the product are stainless steel AISI 304 made.

- Loading rail for one format of pouch, AISI 304 made. The pouches infeed is performed by the operator manually and/or with the rail

- Starwheel for one format of pouch, AISI 304 made.

- Dosing valve support, managed by a pneumatic system with up / down movement.

- Volumetric filling unit composed by: ⦠Nr 1 volumetric dosing unit from 5 to 260 cc in AISI 316 L stainless steel ⦠Nr 1 three ways DN15 rotary valve ⦠Nr 1 pneumatic 0.5â â 2 ways no drop valve with shut off nozzle ⦠Flexible hose

- Single head capping unit composed by: ⦠Nr 1 vibrating base cap sorter / feeder AISI 304 made ⦠Nr 1 caps chute in s/steel AISI 304 with photocell ⦠Nr 1 caps releasing head ⦠Nr 1 pneumatic motor ⦠Nr 1 s/steel chuck for one size of plastic screw cap

- Electrical regulation of the height of the capping head.

- A security clutch system stops the machine in case of problems on the star so as not break any pouch.

- Electrical photocell is posed in the enter ; in case of no arrival of pouches the machine doesnât run.

- Electrical photocell is posed on the exit ; in case of problem on the plant the machine stops.

- Electrical photocell stops the machine in case the caps chute is empty, as to avoid any pouch to pass through the machine without cap. Automatically, the machine re-starts as the caps chute is again full of caps.

- Control panel in S / S AISI 304 with auxiliary service at 24 volts.

- Machine managed by PLC.

- Touch screen.

- Height of conveyor from floor 900 ± 50 mm.

- 220V 50Hz single phase, 8 A.

- Air consumption, about 250 Nl/min.

- Material: Stainless steel

- Voltage: 220-230V

You might also like

Semi automatic packaging machine for filling and capping jars.

- Material: Stainless steel

4 Heads vacuum bottle filling machine serves as a professional semi-automatic filling and dosing machine for filling glass bottles with various fluids.

- Material: Stainless steel

- Operation mode: Manual

- Type of the equipment: Individual machine

Semi-automatic dosing machine, designed for filling and capping different spouted pouches with various liquids.

- Material: Stainless steel

- Operation mode: Semi-automatic

The piston-operated pneumatic liquid dispenser is a semi-automatic filler used for dispensing various low viscosity liquids ranging from 10 to 100 ml in volume.

- Compact tabletop installation

- Simple control with two operating modes: manual and semi-automatic

- Suitable for liquid products with low viscosity (from water to oil)

- Optional compressed air compressor available

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Continuous mode

- Voltage: 220-230V

The piston filler is designed for dosing different types of liquid products in the food, chemical, pharmaceutical and cosmetic industries.

- Material: Stainless steel

- Operation mode: Manual

- Type of the equipment: Individual machine

The manual bottle filler is designed to fill liquids in glass bottles.Â

- Productivity: 650 psc/h

- Material: Stainless steel

- Operation mode: Manual

TEPF is a pneumatic dispenser for dosing several kind of products. The machine allows the filling of food, chemical, cosmetic, or pharmaceutical products into diverse type of bottles and jars.

Price depends on the product used.

- Material: Stainless steel

- Operation mode: Automatic Manual

- Type of the equipment: Individual machine

Chocolate fountain attracts the attention of customers thanks to its stylish design, and can be used to top ice cream cones, to fill cups with hot chocolate drinks etc. Price is for the machine only. You can purchase additional mobile counter, covering rings or various nozzles.

- Material: Stainless steel

- Voltage: 220-230V

A range of pneumatic vertical filling machines for dosing liquids with viscosity is similar to water.

- Type of the equipment: Individual machine

4 Heads vacuum bottle filling machine serves as a professional semi-automatic filling and dosing machine for filling glass bottles with various fluids.

- Material: Stainless steel

- Operation mode: Manual

- Type of the equipment: Individual machine

Hydraulic sausage filling machine is the ideal equipment to fill sausage of various specifications and is suitable for filling in different kinds of casings.

We offer different meat processing machines.

- Material: Stainless steel

- Engine power, kW: 0,37

- Weight: 92 / 135

- Voltage: 380-400V

A simple mobile filler is an economically advantageous solution for filling barrels. We also offer barrel top filler.

- Material: Stainless steel

Compact digital filling machine for accurate dosing of viscous liquids such as honey, pastes, sauces, and oils. Designed with food-grade materials, easy-to-clean components, and precise digital control, it is ideal for small production, workshops, and laboratories.

- Operation mode: Semi-automatic

Normit AP tensometric filling machine is a weight-based system for filling honey into barrels.Â

- Material: Stainless steel

- Country of origin: Slovakia

This head capping machine has a magnetic clutch, ribbed spindle. It is semi-automatic and closes bottles or jars with PFP aluminum caps, twist off caps or plastic screws. The price depends on the cap, product you are filling, and capacity.

Price depends on the lid, the product you are filling, and the container.

- Productivity: 400-700 psc/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 220-230V

The filling and filtering machine serves as a reliable source for the liquid product supply while also keeping it in a liquid state.

- Productivity: 1000 kg/h/

The screw pump is used for transferring "un-pumpable" products. A great choice for those who work with hard to move liquids and need to move them as quickly as possible.

- Material: Stainless steel

- Voltage: 380-400V

Cost-effective system for filling barrels on the basis of a scale for filling the product with a pump.

Mechanical vacuum filler, regulated by an electronic system, with a frequency converter.

We offer different hopper capacities.

- Material: Stainless steel

- Operation mode: Automatic

- Country of origin: EU

- Volume: 40/ 90/ 125 / 200l

Automatic Bag-in-Box filler intended for filling the bag-in-box bags with finished products (both hot and cold) - with a bag volume of 3 to 20 liters.

- Productivity: 180 -240 psc/h

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Continuous mode

- Voltage: 220-230V