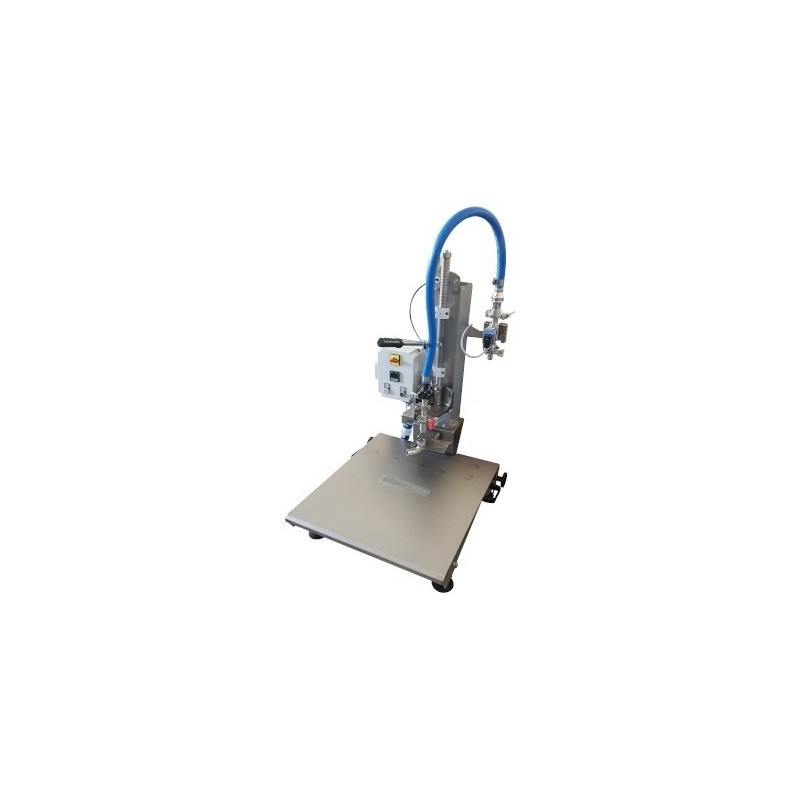

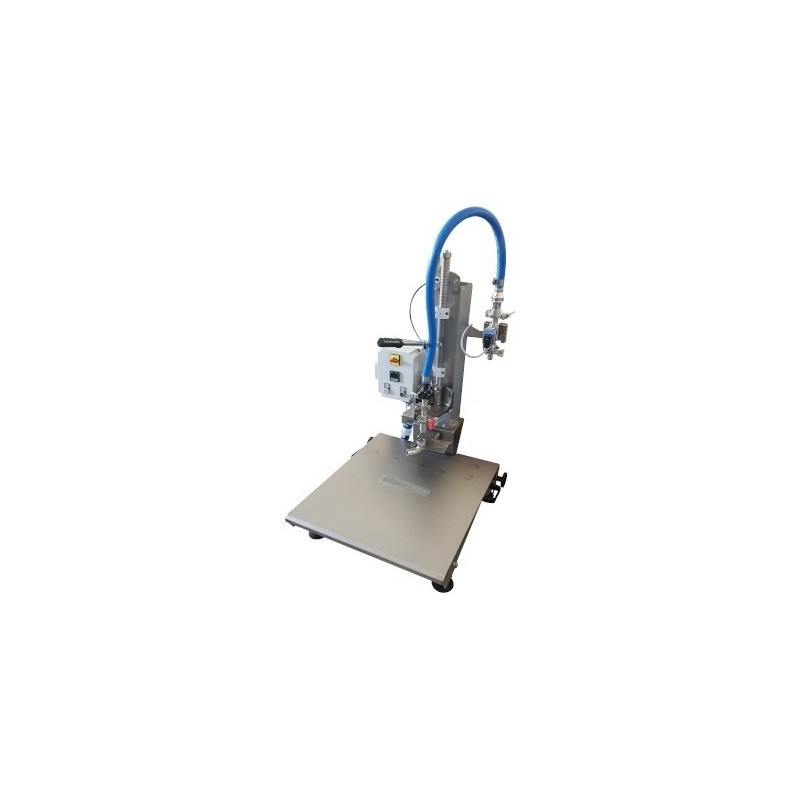

Bag in Box filler for hot filling EI B12

The device is designed for filling Bags In Boxes. Suitable for filling hot non-viscous products. The device can be purchased separately or with additional options - trolley and magazine.

The device is designed for filling non-viscous products into bags in boxes.

It allows filling of wine, oils, fruit juices (depending on the type of flow sensor. The device can also be used for filling hot liquids. Ideal solution for companies with a small annual production volume.

Simplicity

The machine is completely made of stainless steel - it is equipped with 4 adjustable legs with the possibility of installation on a support table (or it is additionally possible to offer a mobile stand / trolley).

It requires no compressed air connection (only if an optional vacuum system is selected). The filling cycle is performed automatically: Start, Filling; Stopping the machine. The operator selects the format and maneuvers the cap extraction and insertion pliers according to the filling procedure on the display. The control panel controls the switching on and off of the external pump (centrifugal or positive displacement). The pulse valve allows manual injection of inert gas at the end of the cycle. The vacuum function is available as an option and requires connection to a 6 bar pneumatic circuit. The possibility to choose between different types of flow sensors ensures optimal use of the device for various different applications.

Accuracy

The electronic panel allows filling with a permitted error rate of ┬▒ 5/10 cl

Hygiene

Possibility to perform steam sterilization at 110 ┬░ C

- Material: Stainless steel

- Operation mode: Automatic

The Bag in Box Filler is designed for filling hot and cold liquids into Bags in Boxes and for Stand Up Pouch packaging.

- The machine fills the bags up automatically.

- Material: Stainless steel

- Principle of operation: Continuous mode

Normit AP tensometric filling machine is a weight-based system for filling honey into barrels.┬Ā

- Material: Stainless steel

- Country of origin: Slovakia

Designed for accurate feeding and packaging of liquids under pressure.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 80l/

Automatic Bag-in-Box filler intended for filling the bag-in-box bags with finished products (both hot and cold) - with a bag volume of 3 to 20 liters.

- Productivity: 180 -240 psc/h

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Continuous mode

- Voltage: 220-230V

- Material: Stainless steel

- Engine power, kW: 0,18/

- Operation mode: Automatic

- Country of origin: EU

- Voltage: 220-230V

Semi-automatic dosing machine, designed for filling and capping different spouted pouches with various liquids.

- Material: Stainless steel

- Operation mode: Semi-automatic

This head capping machine has a magnetic clutch, ribbed spindle. It is semi-automatic and closes bottles or jars with PFP aluminum caps, twist off caps or plastic screws. The price depends on the cap, product you are filling, and capacity.

Price depends on the lid, the product you are filling, and the container.

- Productivity: 400-700 psc/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 220-230V

Hydraulic piston fillers for the food processing industry, filling machines for meat and sausages, ideal equipment for meat industry producers and butchers.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Volume: 20l/ 30l/ 50l

A simple mobile filler is an economically advantageous solution for filling barrels. We also offer barrel top filler.

- Material: Stainless steel

VBF is a fast, robust, and versatile vacuum bottle filler.┬ĀThis is the filling machine you are looking for if you desire to increase the production volume of your homemade products, and professionalize the bottling of wine, oil, beer, fruit juices, or other products.

- Operation mode: Semi-automatic

- Principle of operation: Continuous mode

4 Heads vacuum bottle filling machine serves as a professional semi-automatic filling and dosing machine for filling glass bottles with various fluids.

- Material: Stainless steel

- Operation mode: Manual

- Type of the equipment: Individual machine

The piston filler is designed for dosing different types of liquid products in the food, chemical, pharmaceutical and cosmetic industries.

- Material: Stainless steel

- Operation mode: Manual

- Type of the equipment: Individual machine

The screw pump is used for transferring "un-pumpable" products. A great choice for those who work with hard to move liquids and need to move them as quickly as possible.

- Material: Stainless steel

- Voltage: 380-400V

Chocolate fountain attracts the attention of customers thanks to its stylish design, and can be used to top ice cream cones, to fill cups with hot chocolate drinks etc. Price is for the machine only. You can purchase additional mobile counter, covering rings or various nozzles.

- Material: Stainless steel

- Voltage: 220-230V

The pneumatic piston filler for pastes and liquids is a semi-automatic dispenser designed for dosing various liquids with a low, medium or high viscosity.

- Tabletop compact model

- Includes a built-in 26 l conical storage tank

- A wide dosing range from 300-2500 ml

- Can also be used for products with a high degree of viscosity

- High dosing speed

- Possibility of working in manual or automatic mode

- Material: Stainless steel

- Principle of operation: Continuous mode

- Volume: 300-2500 ml

- Voltage: 220-230V

Cost-effective system for filling barrels on the basis of a scale for filling the product with a pump.