Milk Pasteurizer MIP M

Tell us if you are producing cheese, milk, yoghurt or ice cream. The difference between the milk pasteurizer and the yoghurt pasteurizer is that the yoghurt pasteurizer is equipped with a detachable arm with a detachable big stirrer and two half lids.

Milk Pasteurizer is an excellent piece of equipment manufactured by people who know perfectly the secrets of milk storage, maintenance and processing.

Milk Pasteurizer is made of high quality materials using the latest equipment and technology. All materials are the most reliable in European market and guarantee a long and trouble-free operation. MIP Pasteurizers are heat exchangers for the heat processing of milk, for the production of white cheese (feta), yoghurt, hard cheese, ice cream, etc. The dairy pasteurizers are available in capacities of 50, 100, 200, 300, 400, 500, 650, 800, 1000 liters.

There are three types of dairy pasteurizers available:

- Milk Pasteurizer

- Cheese Pasteurizer

- Ice cream Pasteurizer

Milk Pasteurizer - Technical specifications

- Ergonomic design and stainless steel AISI 304 food grade material.

- Excellent insulation of the tank with double wall and two component environmentally friendly polyurethane foam.

- Heat exchanger manufactured with laser technology, designed for faster water flow that provides optimal efficiency and combines energy saving and high durability.

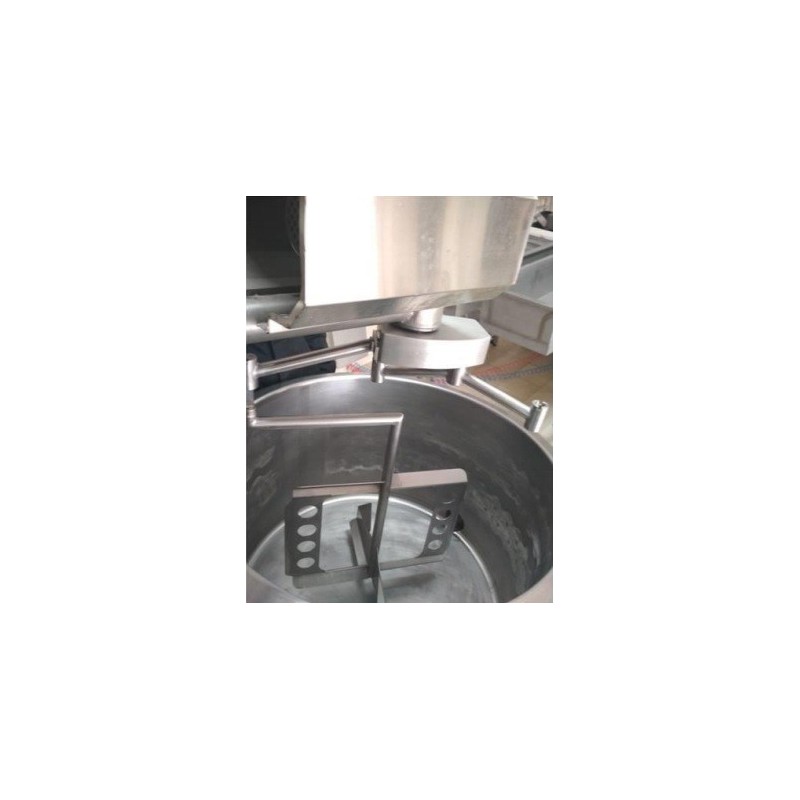

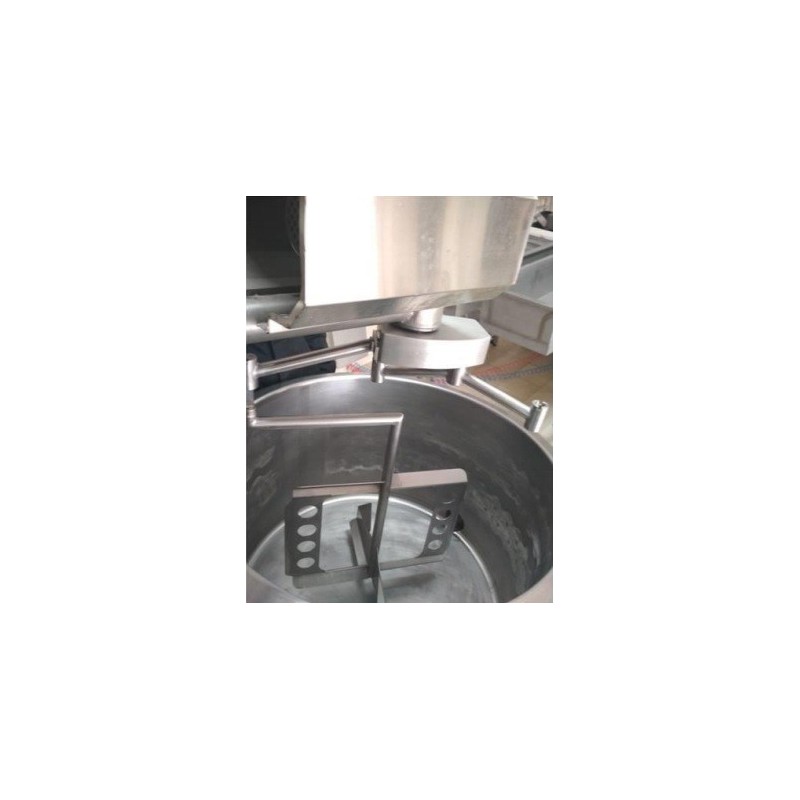

- Integrated agitation motor with a special agitator per model depending on the use.

- Adjustable heavy duty stainless steel feet for leveling on uneven surfaces.

- Stainless steel dipstick for measurement of the content.

- Stainless steel immersion sensor NTC IP68 AISI316 for temperature indication.

- Available in a variety of different capacities.

- Stainless steel electronic control panel with color touch screen for easy control of the pasteurization process.

Dairy Pasteurizer - Functional characteristics

- Thermal milk processing (heating, cooling and agitation) is fully controlled via configurable software.

- Automatic start/stop of agitation option.

- Audible and visual alarms for the completion of each phase.

OPTIONAL:

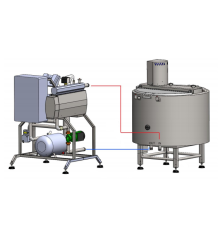

- HEATING Hot water supply to the pasteurizer circuit can be achieved with gas or oil boiler or electric heater

- COOLING For the cold water supply to the pasteurizer circuit, ice-banks can be used.

MILK PASTEURIZER

MIP milk pasteurizing equipment is designed explicitly for the heat processing of milk and is the most economic model.

Functional characteristics of a Milk Pasteurizer

- Can be combined with a processing line for cheese production.

- Low speed agitation motor (30 rpm), installed on a special elevated base on the lid, for easy cleaning and service.

- Stainless steel fully opening lid.

CHEESE PASTEURIZER

MIP Cheese Pasteurizer is a reliable and extremely functional solution for milk pasteurizing and coagulation in the same tank thus saving equipment cost, space and userŌĆÖs time.

Functional characteristics of a cheese pasteurizer

- Powerful agitation motor, protected by stainless steel cover, controlled by inverter for accurate regulation of the agitation speed.

- Stainless steel controller on the pasteuriser with switch for the agitation direction (clockwise or counterclockwise), LED indicators and emergency switch for immediate stop of the agitation.

- DN80 outlet valve for quick liquid drainage.

- Installation of the agitation motor on removable and rotating stainless steel arm.

- Removable stainless steel agitation paddle for milk.

- Removable stainless steel cutters of high durability and elasticity for the coagulated mixtureŌĆÖs cutting.

- Fully removable stainless steel lid of separating type.

- Special stainless steel detachable filter for the cheese curd holding while emptying the vessel.

ICE CREAM PASTEURIZER

MIP Ice Cream Pasteurizer is a highly functional solution for the pasteurization and mixing of ice cream mixture

Technical specifications of an ice cream pasteurizer

- Powerful agitation motor rotating at 3000rpm.

- Stainless steel agitator with special blades.

- Protective stainless steel of the blades.

- Functional characteristics

- Agitation motor installed on fixed part of the lid for absolute stability.

- Opening and removable top covers for easy filling of raw material into the vessel.

- Milk inlet with low foaming system.

- Material: Stainless steel

- Country of origin: EU

- Volume: 50l/ 100l/ 200l/ 300l/ 400l/ 500 l/ 650l 800 l / 1000l/ 1250l/ 1500l

You might also like

Pasteurizer, cheese boiler is designed for processing milk, yogurt, fruit juice or other liquids.┬Ā

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24

- Volume: 200l/ 300l/ 500l

The Milk Cooler has a simple design, which allows for easy and safe operation. it meets the requirements of all dairy production facilities.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 50l/ 100l/ 200l/ 300l

- Voltage: 380-400V

Milk cooler tank designed for cooling milk and other dairy products. The tank is available in 13 different capacities, covering a range from 50 liters all the way up to 2,500 liters, capable of meeting the needs of all dairy & cheese production facilities. We offer 2 or 4 milking options. Prices are displayed for the milk cooling tank with 4 milking.

- Material: Stainless steel

- Principle of operation: Batch mode

Pasteurization dipping tub is suitable for the heat treatment of packaged fruit preparations, (jams, fillings, hams) or fermented preparations (vinegar, beer) and pickles to preserve them, and to eliminate harmful microorganisms.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 200l/ 300l

For a price quote or for a free consultation, send us a request.

- Productivity: 90l

- Material: Stainless steel

- Heating power, kW: 6/

- Principle of operation: Continuous mode

- Voltage: 380-400V

The cooling units have a compact design. They are space-saving and easy to assemble. The chiller in standard version can work at water outlet temperatures from +10┬░C to +25┬░C.

For more information, send us an email to sales@normit.com┬Ā

- Volume: 18 l/ 30l

- Voltage: 220-230V

Electric heating panel with three different power possibilities: 12, 24 and 48 KW ŌĆō excellent product manufactured by people who perfectly know the secret of product storage, maintenance and processing.

- Heating power, kW: 12/ 24/ 48

- Country of origin: EU

Electric pasteurizer suitable for pasteurizing beverages as well as filling up bottles or bag-in-boxes. We offer 3 production capacities. The basic pasteurizer model comes without the manual BiB filler module.

- Productivity: 180 l/h / 300l

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 380-400V

The plate pasteurizer is designed for partial decrystallization and pasteurization of honey preheated to a temperature of 30-35 degrees.

- Principle of operation: Continuous mode

- Country of origin: EU

The pasteurization equipment MGGP is suitable for the heat treatment of low viscosity foods as well as drinking water.

- Productivity: 500 l

- Material: Stainless steel

- Principle of operation: Continuous mode

We offer many different types of pasteurizers.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

The multifunctional cooking and pasteurization kettle with manual tilting is a simple device designed for the entire jam production process: from cooking the fruit mixture to the subsequent pasteurization of finished products directly in jars. It allows you to prepare the product in a container and then, using an additional basket, pasteurize the filled jars without the need for any additional equipment.

- 6-stage regulation of the built-in heating allows you to set the optimal conditions for cooking the fruits and subsequent pasteurization without the risk of burning or loss of quality.

- The manual tilting mechanism with a three-stage adjustment and a maximum tilt angle of 110┬░ ensures convenient emptying of the container and dosing of the finished product with virtually no losses.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 2,6 / 6,5

- Volume: 50l/ 100l

The long-term pasteurization tank is a compact solution for the heat treatment of milk in order to disinfect the microflora and eliminate harmful microorganisms. This unit belongs to the category of long-term pasteurization systems, heating milk between 63 and 95 degrees Celsius, and maintaining it at a specific temperature for a set period of time. The special design allows not only for pasteurization of milk in the flow, but also for sequential cooling, by feeding cold water into the heat exchanger after heating.

- External forced circulation with a heat exchanger

- Highly efficient steam heating via the heat exchanger

- Can also be used as both a pasteurization and cooling unit

- High-performance milk pump

- Compact vertical design

- Heating: Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 1000l

The universal bath pasteurizer is used for processing a wide range of different food products, such as ready meals, sausages, hams or liquid products. Effective temperature regulation and a hygienic stainless steel design.

A compact electric pasteurizer with a heating power of 5 kW is used for long-term batch pasteurization of milk, which includes heating milk to a temperature up to 100 degrees C and maintaining it for a selected period of time. The milk pasteurizer can also be used in the form of a Milk pot to heat milk for feeding calves.

- High heating power (5ŌĆ»kW) on a 220ŌĆ»V single-phase connection

- Stirrer with bottom scrapers that prevents milk from burning when directly heated

- Direct electric heating with a multi-stage power switch

- Hygienic design for simple and easy cleaning

- Simple system for removing and lifting the top hatch with an agitator

- Absence of blind spots where bacteria can grow

- Heating: Electricity

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Heating power, kW: 5

- Principle of operation: Batch mode

- Volume: 50l/ 100l/ 150l

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

We offer different types of dairy pasteurizers. Tell us if you are producing cheese, milk, yoghurt or ice cream and we will help you pick the right pasteurizer for you.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

- Volume: 200l/ 300l/ 500 l/ 800 l / 1000l

Pasteurization dipping tub is suitable for the heat treatment of packaged fruit preparations, (jams, fillings, hams) or fermented preparations (vinegar, beer) and pickles to preserve them, and to eliminate harmful microorganisms.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 200l/ 300l

The professional yogurt making machine is designed to produce a wide range of yogurt production, e.g. creamy, liquid drinking, greek, white, organic, fruit yogurts. The machine can be used by farms and small dairy factories.

- Material: Stainless steel

- Principle of operation: Batch mode

The price is indicated with a semi-automatic control panel

The vacuum cooking kettle is designed for use in public catering establishments (restaurants, hotels, catering companies) and small manufacturing businesses. This equipment enables boiling, blanching, frying, evaporation, pasteurization, mixing or stirring.

- A unique multifunctional device

- Possibility to cook/fry under atmospheric or vacuum conditions

- Laboratory version of a Vacuum Fryer

- Built-in condensation and secondary steam removal system

- Intense electric heating

- Sectional basket with a lid

- Built-in system for separating and removing excess liquid from the product

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Volume: 20l

- Oil volume: 8l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The price is indicated without the heating and cooling sources

The continuous heat treatment and filtration unit is suitable for processing products of various viscosities, such as honey, jam, baby food, sauces, ketchup, tomato soup and many other products. Depending on the model, it can have a productivity ranging from 250 up to 2000 kg/hour.

- Universal application for continuous pasteurization

- Suitable for pasteurization of heat-sensitive products

- Ideal solution for thick and viscous products

- For short-term pasteurization followed by cooling

- Productivity: 250 kg/h/ 500 kg/h/ 1000 kg/h/ 2000 kg/h

- Principle of operation: Continuous mode

- Country of origin: Slovakia

This multifunctional cooking machine with two baskets is designed for different ways of use and is suitable for a lot of variety of businesses - any enterprise or any participant of the HoReCa market. With the help of this equipment, you can cook, pasteurize, or blanch.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 135 +135 / 220+220

The tubular pasteurizer is typically designed for pasteurizing cream in butter production lines. These pasteurizers are commonly used in dairy processing industrial facilities, especially in butter production and other related sectors.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The pasteurization kettle with manual tilting is a modern device designed for gentle heat treatment of milk and dairy products, which allows for their effective pasteurization, extends shelf life and increases safety, while preserving the original taste and nutritional values. The 6-stage heating regulation of the powerful integrated heater, allows the milk to be reliably pasteurized directly in the container with a sandwich bottom, ensuring even heat distribution.

- Ideal solution for small-scale and home production of dairy products

- Removable lid for easy inspection and manual mixing of the product

- Option to equip it with a drain valve for discharging liquid products

- Even heating without burning thanks to the sandwich bottom

- Easy connection to a single-phase 230 V power supply

- Material: Stainless steel

- Heating power, kW: 6,5

- Volume: 50l/ 100l

- Voltage: 380-400V