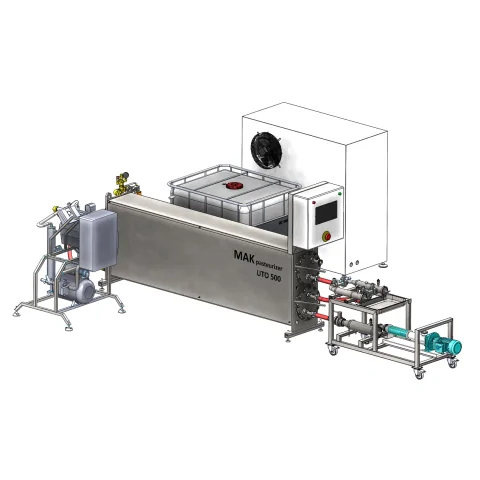

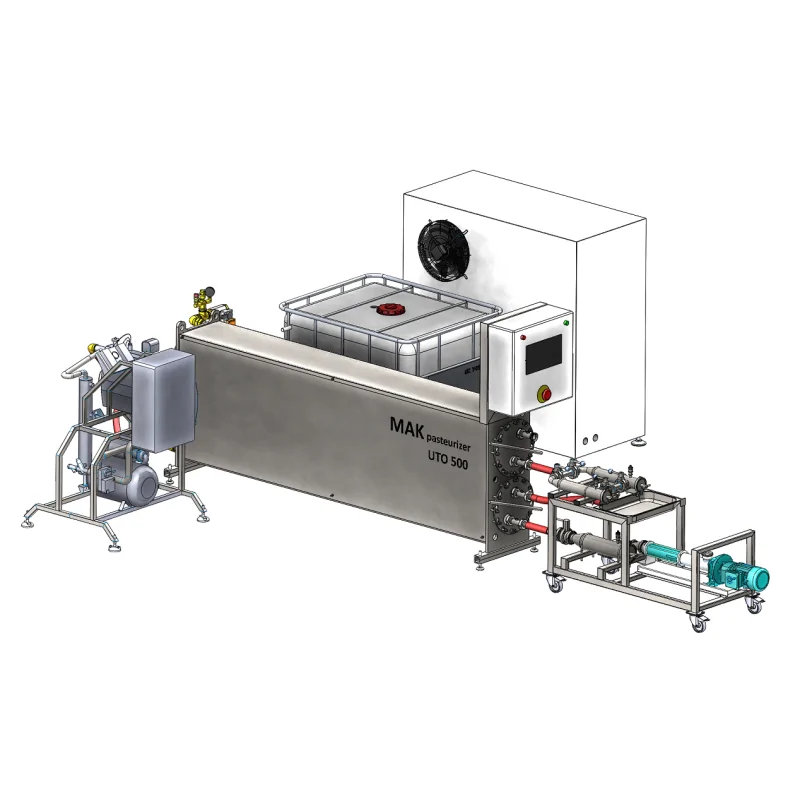

Flow Pasteurizer UTO FLOW

The price is indicated without the heating and cooling sources

The continuous heat treatment and filtration unit is suitable for processing products of various viscosities, such as honey, jam, baby food, sauces, ketchup, tomato soup and many other products. Depending on the model, it can have a productivity ranging from 250 up to 2000 kg/hour.

- Universal application for continuous pasteurization

- Suitable for pasteurization of heat-sensitive products

- Ideal solution for thick and viscous products

- For short-term pasteurization followed by cooling

The UTO installation is designed for continuous pasteurization and subsequent cooling of various products in shell-and-tube heat exchangers with special devices in the form of partitions to increase the speed of the coolants movement and, accordingly, increase the intensity of heat transfer. This ensures uniform heat treatment and guaranteed pasteurization of products in the flow, making it even possible to process heat-sensitive products while preserving most of the beneficial substances inside them. The result is high-quality natural products with a long shelf life and attractive appearance.

The continuous FLOW pasteurizer is suitable for processing the following products:

|

|

|

|

|

|

|

|

Advantages:

- The entire structure of the pasteurizer is made out of food-grade stainless steel, the heat exchangers are made out of high-quality seamless pipes built to withstand high pressure and create a perfect tight fit.

- High surface area and heat transfer rate of the heat exchangers.

- Heat exchangers are easy to disassemble, wash and assemble. They are designed to be easily disassembled, cleaned and reassembled in a minimum amount of time (this is very rare with other heat exchangers).

- The improved design of the pasteurizer allows you to minimize the space for installation. The heat exchangers are located one above the other mounted on a common supporting frame. The operator can track any cycle of the pasteurizer and clean it without leaving his workplace.

- A two-stage filtration system includes the first cleaning stage before entering the heating section, and the second before cooling.

- A special pump for feeding the product allows you to process not only products with a homogeneous structure, but also raw materials containing different fractions, for example, tomato paste or ketchup with tomato pieces.

- The control system includes adjustment of the speed of the products movement (pump for supplying the product), a temperature controller for adjusting and maintaining the required temperature in the heating section and cooling section, pressure sensors for safe operation and monitoring of the filtration system.

Basic version

It consists of 2 tubular heat exchangers located one above the other on top of a supporting structure, with a double filtration system, a by-pass fine filtration system, a special pump for thick and viscous products, a heating system (on some models) and a control panel.

Operating principle

The product is loaded into the system using a product pump where it moves through a coarse filter into the heating system of the tubular heat exchanger. The tubular heat exchanger consists of a casing and pipes located inside. The product, entering the heat exchanger, moves through the pipes surrounded by hot circulating water. Heating of the product occurs due to the heat transfer to the tubes filled with the product.

A heat exchanger with heating elements immersed in water and a circulation pump is connected to the tubular heat exchanger, or a separate installation is used as a source of hot water supply, which functions as a closed heating system (depending on the model).

The product, passing through the tubular heat exchanging system, warms up to a set temperature. The heating temperature is regulated by technical conditions and production technology. Subsequently, the product is supplied through a piping system and right through a fine filter into the tubular heat exchanger, where it is cooled. The operating principle of the cooling section is identical to the heating section, in that case cold water at a temperature of 7 degrees is used as a coolant(refrigerator/chiller can be offered as an additional option).

To reduce the operating costs of the refrigeration machine, it is recommended to install a buffer tank (optional), where the water heated by the product is returned from the cooling section of the pasteurizer. The chiller is connected in such a way as to ensure cooling of the water in the tank; an additional pump (optional) is required to supply the coolant into the heat exchanger.

Options:

- Source of hot water supply for certain models (different heating powers to choose from)

- Refrigerator/chiller

- IBC Container Insulation Casing

- Additional coolant pump

- Capacity: 250 kg/h/ 500 kg/h/ 1000 kg/h/ 2000 kg/h

- Principle of operation: Continuous mode

- Country of origin: Slovakia