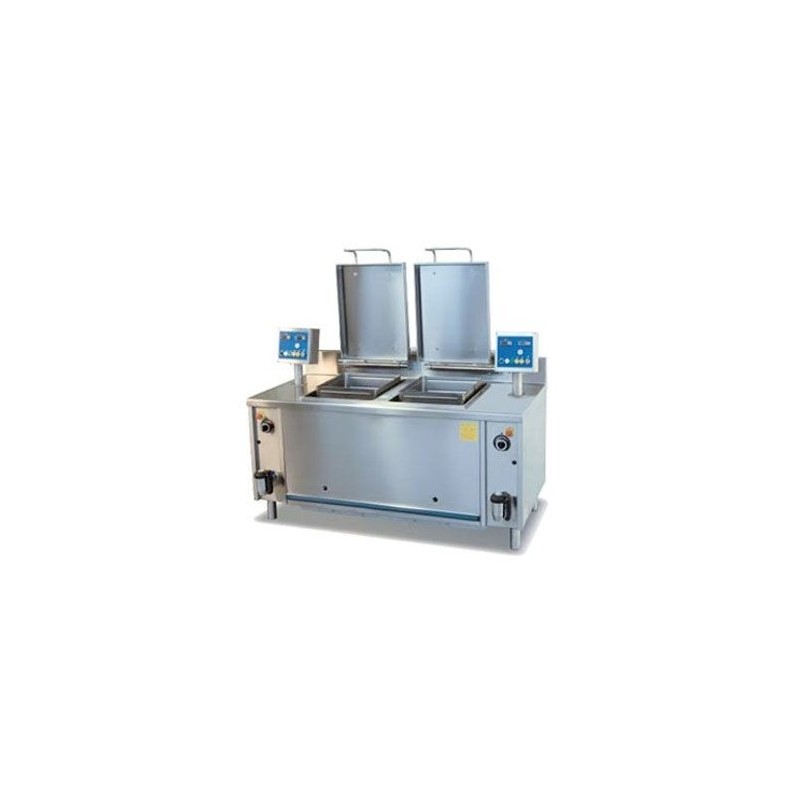

Automatic double-basket cooking boiler

This multifunctional cooking machine with two baskets is designed for different ways of use and is suitable for a lot of variety of businesses - any enterprise or any participant of the HoReCa market. With the help of this equipment, you can cook, pasteurize, or blanch.

Automatic multi-functional double-basket cooker which helps you to process different types of products. Compact, easy to use, and presents excellent results.

General features:

- 6 models from 2x135l to 2x220l

- Quick to clean, guaranteeing high-level hygiene thanks to the satin-finished surfaces

- Simple to inspect thanks to the removable front panel providing access to the technical compartment

- Thermally insulated with high-density 96/128 kg/m3 bio soluble fiber felt featuring excellent thermal stability and which significantly reduces heat dispersion

- Delicate treatment of all food types, at the service of the Chef

- Adjustable balanced lid, perfect to prevent condensate from dripping into the tank

- Thick, anti-corrosive materials ensure the sturdiness and resilience of the pot over time

Cooking tank

- Tank completely in satin-finished AISI 316 stainless steel

- Baskets in satin-finished AISI 316 stainless steel

- Overflow device and starch skimming and discharge valve

Lid

- The lid is made in AISI 304 15/10 stainless steel, featuring a chrome-plated steel hinge with pre-loaded spring and a thermal handle.

- Gauge to control pressure inside jacket

- Manual relief valve to depressurize the jacket during heating

- Adjustable mixer in chrome-plated bronze with hot and cold water

- Weight-loaded safety valve calibrated at 0.5 bar

Frame, panels, and supporting structure

- Supporting structure in 20/10 stainless steel mounted on adjustable steel leveling feet from 150mm to 180mm

- External walls in AISI 304 10/10 stainless steel with a satin finish

- The satin-finished ledge in AISI 304 15/10 stainless steel

Basket tilting system

- Automatic tilting system by means of electric actuator

- Possibility to adjust the position of the basket to drip and drain, or alternatively direct front draining

- Power supply 400V 3N 50Hz

Heating system options:

Direct gas

- Ignition by means of manual piezo igniter and pilot flame

- Heating by means of high-performance tubular burners in AISI 304 stainless steel

- Ventilation grille

- Set of nozzles for various types of gas

- Tap with safety valve with thermocouple

- Safety thermostat to protect against overtemperature and lack of water

Indirect steam with jacket

- Heating by means of steam (from user mains) with solenoid throttle valve allowing a gradual steam intake in the jacket

- Control of pressure in a jacket by means of safety valve calibrated at 0.5 bar, manual vacuum relief valve, and pressure gauge

Direct electric

- Heating by a series of heating elements

- Heating element safety thermostat with heating block due to overtemperature or insufficient water level

- Temperature control (50¬įC ‚Äď 120¬įC)

- Standard power supply 400V-3N-50Hz

Specifications:

|

HEATING |

MODEL |

CAPACITY      lt. |

DIMENSIONS L x P x H mm |

BASKET DIMENSIONS  mm |

Power   (kW) |

CONSUMPTION |

||||

|

Gas |

Electric |

G.P.L. kg/h |

Metano H m3/h |

Metano L m3/h |

Vapore kg/h |

|||||

|

DIRECT     GAS |

MCP 30.G |

135 + 135 |

1800x900x900 |

2 x (480x650x565) |

2 x 24 |

0,2 |

3,78 |

5,08 |

5,92 |

- |

|

MCP 40.G |

220 + 220 |

2500x1000x900 |

2 x (720x800x565) |

2 x 39 |

0,2 |

6,16 |

8,26 |

9,60 |

- |

|

|

STEAM BOILING |

MCP 30.V |

135 + 135 |

1800x900x900 |

2 x (480x650x565) |

- |

0,2 |

- |

- |

- |

2 x 70 |

|

MCP 40.V |

220 + 220 |

2500x1000x900 |

2 x (720x800x565) |

- |

0,2 |

- |

- |

- |

2 x 100 |

|

|

DIRECT   ELECTRIC |

MCP 30.E |

135 + 135 |

1800x900x900 |

2 x (480x650x565) |

- |

2 x 13,7 |

- |

- |

- |

- |

|

MCP 40.E |

220 + 220 |

2500x1000x900 |

2 x (720x800x565) |

- |

2 x 25 |

- |

- |

- |

- |

|

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 135 +135 / 220+220

SnackPro blancher will prepare different types of products making it a great solution for blanching large volumes of fruits and vegetables in a short time.

- Heating: Electricity

- Heating power, kW: 40/ 90

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 220l/ 500 l

Cooking kettle for making syrups, caramel, sugaring paste as well as processing and producing various thick and viscous products. Often used for dissolving sugar and producing various saturated and supersaturated solutions.

- Built-in heating with thermal oil up to 150 degrees Celsius

- Anchor frame stirrer for rapid dissolution

- Conical bottom design of the working container without dead zones

- Heating: Electricity

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 200l/ 300l

- Total power, kW: 19

Specialized vacuum cooking kettle for sweet masses, ideal for commercial applications and medium to large scale food production.

For a price quote, send us a request.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 200l

- Dimensions, mm: 2055x1800x1980

Atmospheric cookers ASC are designed for efficient mixing, heating and cooking products for food and cosmetic industries. Volume, l: 100 l.

- Heating: Electricity

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 100l

The universal cooking boiler with an integrated homogenizer and a capacity of 1200 liters is designed for efficient mixing, heating, cooking and homogenizing of products for food, pharmaceutical and cosmetic industries such as jams, marmalades, syrups, fruit juices, nectars, beers, creams, ointments, soaps and many others.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

This is a 400 l capacity heating boiler, we offer different capacity commercial cooking boilers.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 25

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 400l

- Voltage: 380-400V

The Economy series of the cooking kettles comprise a thick-walled stainless steel container with an electric mixer mounted on the quick-release upper housing. The installation allows you to mix and stir products during processing. The thick bottom of the pot allows it to be installed on all types of heating surfaces (gas, induction or electric stove).

The Economy version is recommended for use with low-viscosity liquid products; If processing more thick and viscous products is necessary, we offer the Premium version of the cooking kettle or the caramel & syrup cooking kettle for extra thick substances.

- Sandwich bottom (multilayer) for use on all types of hobs, including induction

- Quick release lid with an electric stirrer

- Safety grid under the upper hull hatch - safe handling when stirring

- Possibility of visual inspection through the safety grid during processing

- Safe loading of components even during mixing

- Material: Stainless steel

- Engine power, kW: 0,12

- Volume: 30l/ 50l/ 100l/ 150l

- Voltage: 220-230V

- Diameter, mm: 400/ 500/ 600

Designed for cooking or blanching vegetables, fruits, legumes, pasta, seafood and other products in a continuous manner.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Complete set of equipment for processing shelled beans, and the production of a soy base with a capacity of 800-1000 liters per hour.

- Productivity: 800 l/h

- Material: Stainless steel

- Country of origin: Slovakia

It is ideal for cooking jams, marmalades, syrups, sauces, creams and other products.

Price depends on the chosen option.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 300l

- Geometric volume: 350 l

The cost is indicated without the control panel, which can be selected and offered separately

A versatile cooking system, featuring an inclined reactor, a duplicator for heating and a frame mixing device, it is designed for processing a diverse range of products through methods such as cooking, boiling, and concentrating at atmospheric pressure. This system is commonly used for the production of syrups, jams, confiture, and honey processing.

- Slanted design with gravity mixing - 25% more efficient!

- External decorative casing made out of polished stainless steel with insulation

- Jacket for the bottom and the walls of the working container along the entire height

- Lid opening sensor for safe operation

- Scrapers are already included in the basic version of the installation

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 300l/ 430l/ 600l/ 1000l

- Voltage: 220-230V 380-400V

The price is set for the basic fryer version without additional modules. If purchasing the fryer together with both of the additional conveyor modules ‚Äď the double conveyor fryer and the paddle conveyor fryer ‚Äď we offer a discount of 300 EUR.

The versatile modular conveyor fryer with a single conveyor belt is used for the continuous frying of a variety of products with a low moisture content, that do not require forced immersion beneath the surface of the oil for even frying.

- Adjustable frying time from a few seconds up to an hour!

- Ability to use the unit as a continuous blancher or boiler for cooking products with a delicate structure

- Modular system, expanding functions with each new module

- Compact, desktop version

- Possibility of periodic frying of products with automatic unloading

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Oil volume: 60l

- Voltage: 380-400V

The electric kettle with a stirring device and manual tilting is suitable for a wide range of applications in food production or professional kitchens. It has an independent frame and built-in intensive electric heating with a wok-shaped, multi-layer ‚Äúsandwich‚ÄĚ base, allowing the heating temperature to reach up to 200 ¬įC.

- High processing temperatures of up to 200 ¬įC

- Built-in, powerful 2,6 kW / 6,5 kW electric heating

- Manual tilting and unloading system with three working positions, allowing a maximum tilt angle of 110¬į

- Professional high-temperature thermometer with a probe in the product

- Air insulation of the outer casing

- Stirring device with stainless steel scrapers for high-temperatures

- Material: Stainless steel

- Engine power, kW: 0,25/ 0,37

- Heating power, kW: 2,6 / 6,5

- Volume: 50l/ 100l

- Stirrer speed, rpm: 18

These gas boiling cookers are manufactured for professional kitchens and also for other food processing factories. This is 150l capacity.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 150l

The vacuum cooking and mixing tank is used to boil products at low temperatures, which helps preserve the natural color, taste and nutrients in the product.

Vacuum equipment is used for cooking premium-quality jams, sauces, fruit and vegetable concentrates.

- Inclined design

- Efficient emptying

- High hygiene standards

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia