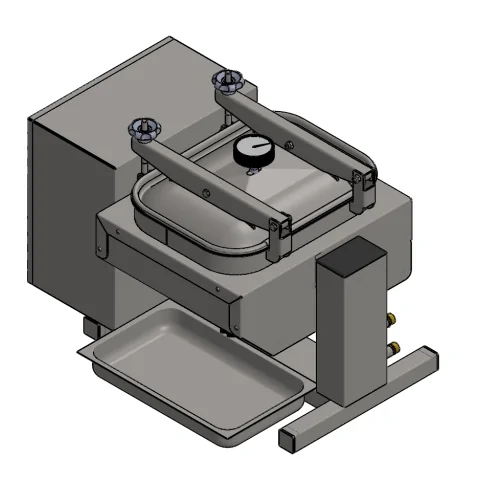

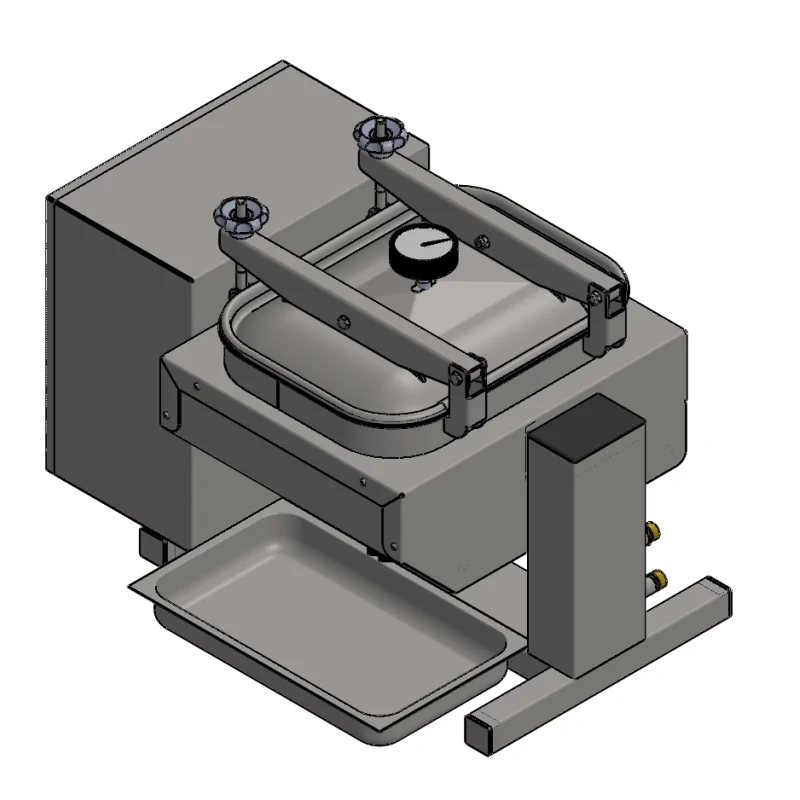

Multi-function vacuum fryer & cooker Idealfry Vac 10L

The price is indicated with a semi-automatic control panel

The vacuum cooking kettle is designed for use in public catering establishments (restaurants, hotels, catering companies) and small manufacturing businesses. This equipment enables boiling, blanching, frying, evaporation, pasteurization, mixing or stirring.

- A unique multifunctional device

- Possibility to cook/fry under atmospheric or vacuum conditions

- Laboratory version of a Vacuum Fryer

- Built-in condensation and secondary steam removal system

- Intense electric heating

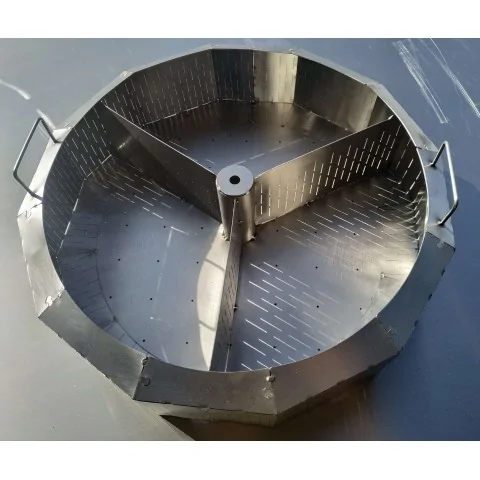

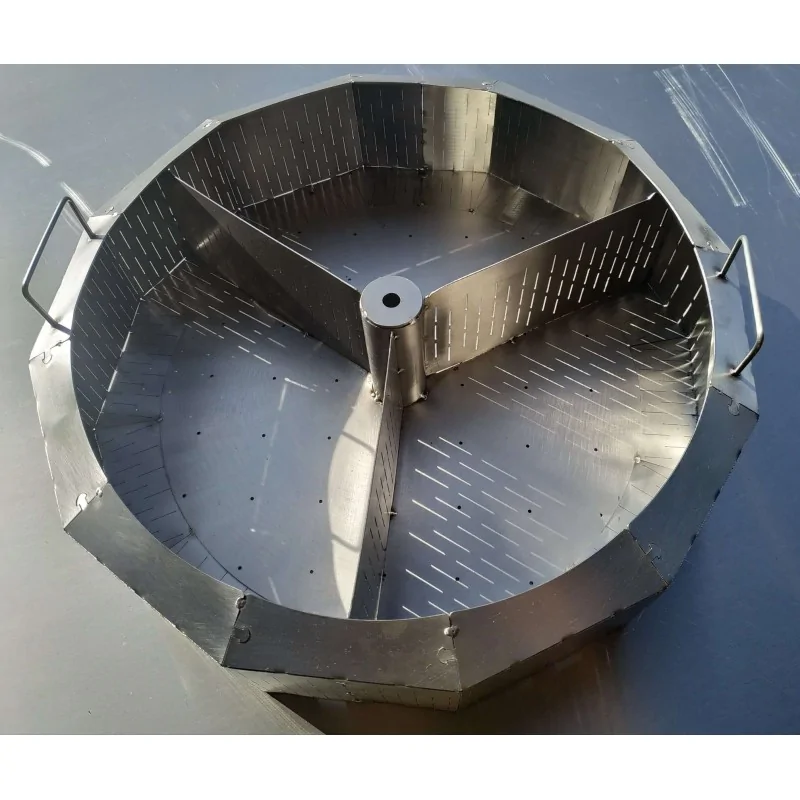

- Sectional basket with a lid

- Built-in system for separating and removing excess liquid from the product

You no longer need to purchase separate devices for each technological process; now, all the listed functions are available in one installation! For people who appreciate high-quality and healthy food!

This professional multifunctional vacuum cooking equipment is designed for the production and processing of various products:

|

|

|

|

|

|

Advantages:

- The possibility of vacuum frying in a basket - using the unit as a vacuum fryer.

- When replacing the basket with a stirring device with scrapers - the installation can be utilized as a frying pan.

- Blanching and cooking food in a basket - utilizing the unit as a blancher or a cooking kettle.

- The multifunctional industrial vacuum unit is straightforward and easy to operate, with an intuitive control menu providing the option to configure and adjust parameters such as temperature, vacuum, turn on/off, and the rotation speed of the mixing device/basket, its tilt, and processing time.

- In this multifunctional setup, products can be processed not only at atmospheric pressure but also under vacuum (at low temperatures). It allows vacuum frying in oil, mixing various products using an additional attachment for whipping, preparing cream and sauces, boiling condensed milk, and pasteurizing various products at pressures below atmospheric.

- Using the multifunctional industrial vacuum unit, you can quickly prepare the product, preserving its original color as well as the nutrients and vitamins it contains! Vacuum processing eliminates air voids in the product, positively affecting the shelf life of products. The vacuum also ensures the retention of beneficial microelements inside the product, as well as its color, taste, and aroma.

- A distinctive feature of the equipment is the special basket - a centrifuge, which will quickly and efficiently remove excess water or oil from the product after processing. The basket is divided into several sections, allowing for parallel processing of various types of products.

- The unique shape of the working vessel, combined with gravitational mixing when the vessel is tilted, enables efficient heat distribution (heat transfer) throughout the entire process. Gravity mixing is 20-25% more efficient than conventional mixing. This feature also facilitates easier unloading of the product from the vessel.

- The special condensation system of the multifunctional industrial vacuum cooker allows the secondary steam generated during processing to condense into water which also improves the efficiency/rate of evaporation from the product.

Basic version

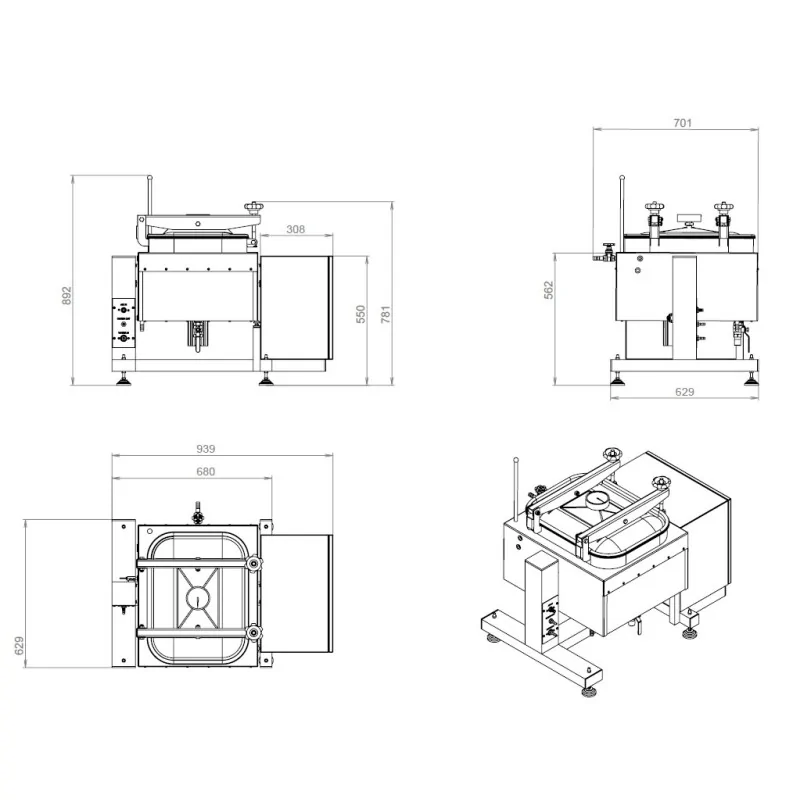

The basic configuration of the installation consists of a compact cylindrical working vessel mounted on a supporting structure with a control panel. It is equipped with bottom electric heating, a special removable basket mounted on a shaft, a vacuum system, a steam removal and condensation system, a centrifuge, and a tilting system for the working vessel. The semi-automatic control allows for adjustments to the heating system, vacuum generation, and basket rotation. In the basic version, the tilting operation is mechanical.

Technical requirements:

- Compressed air source for vacuum generation

- Water supply source for supplying the secondary vapor condensation system

Processes:

|

|

|

|

|

|

|

|

|

|

Options:

- Mixing device with scrapers

- Additional basket

- Control based on a touch panel controller

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Volume: 10l

- Oil volume: 8l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar