Scraped surface heat exchanger HE

The price is indicated without the control unit

The heat exchanger is designed for efficient and gentle heat treatment: heating and cooling liquid and pasty products, including those with a high viscosity, such as jam, chocolate, caramel, glazes, creams, marinades, baby food, honey, fish or meat stuffing and many similar products.

- Uniform thermal processing of thick and viscous products thanks to the supply of the coolant into the duplicator

- Efficient heat transfer due to especially shaped blades

- Continuous operation that does not allow the product to locally overheat or overcool

- Intensive heat transfer due to the internal mixing of the product with scrapers

Scraped surface heat exchangers are used where it is necessary to efficiently and evenly heat/cool thick and viscous products, when their consistency prevents effective heat transfer, and the product itself can stick to the walls, thereby further impairing heat transfer.

Scraped surface heat exchangers are often used in the food, pharmaceutical, and chemical industries to process products such as:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Scraped surface heat exchangers are used not only for thick, but also for heat-sensitive products: products based on beaten eggs, minced emulsions, confectionery fillings, cream cheeses, whey proteins, fish and meat. Including crystallizing products that change their consistency during processing, these include: margarine, pastes, lard, creams based on vegetable and animal fats used in the confectionery industry. Scraped surface heat exchangers can also process products containing solid pieces and inclusions of various ingredients.┬Ā

Advantages:

- Scraped surface heat exchangers have a great advantage over other types of heat exchangers. This heat exchanger combines the traditional principle of heat transfer and a unique mixing system using special scrapers, which improves the efficiency of heat transfer, heat distribution inside the product and significantly reduces product deposits on the walls of the unit.

- The special shaft and shape of the scrapers without blind spots guarantees high standards of hygiene during processing; the shape of the blades carefully mixes the product without destroying its structure.

- Large heat exchange surface area in a limited space, an efficient and productive, yet compact installation.

- The mixing device is easily removed from the heat exchanger for convenient replacement of scrapers.

- Guarantee of consistently high product quality after processing due to the continuous nature of the process, which is especially important, for example, in pharmaceutical production.

- Materials of the highest quality: all parts in contact with the product are made out of high quality AISI 304 stainless steel.

- The heat exchanger can be integrated into any production line or any manufacturing process, allowing the required process to be carried out quickly, efficiently and very hygienically.

- A wide selection of heat exchanger options, materials, and accessories allows you to choose the scraped surface heat exchanger that best suits your specific requirements.

Processes:

|

|

|

|

|

|

|

|

Basic version

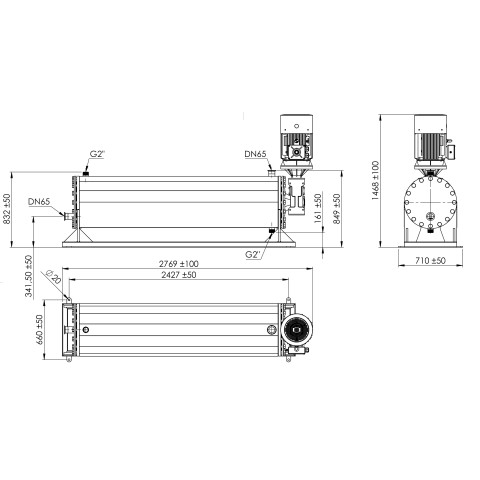

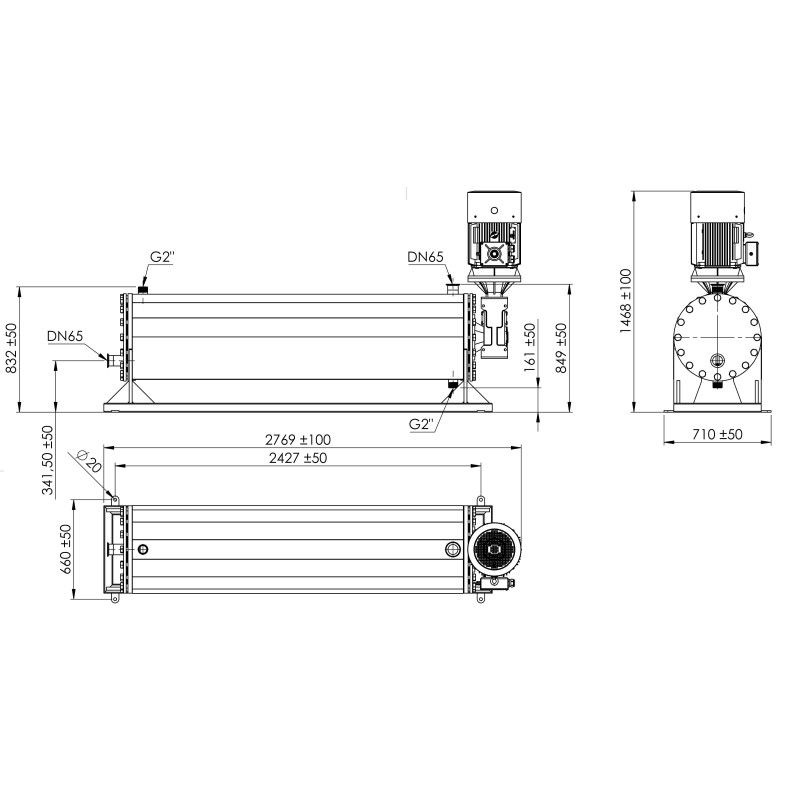

The scraped surface heat exchanger consists of a supporting frame structure, a high-pressure cylinder, a coolant duplicator, an external decorative housing, and a stirrer shaft with electrically driven scrapers (the control panel is not included in the basic delivery package). Depending on the heat exchange area, the unit can be designed in vertical or horizontal configurations. Scraped surface heat exchangers can be connected to an existing heating or cooling source, or alternatively, they can be supplied with their own heating/cooling station (optional).

Principle of operation

The product is fed into the cylindrical housing where it moves tangentially to the heating or cooling medium supplied into the system. Continuously rotating scraper blades remove the product sticking to the cylinder walls, ensuring even heat distribution throughout the system. Enhancing heat transfer efficiency is achieved by increasing the speed of the coolant. The rotor speed can be varied to attain the desired quality and quantity of the product.

Options:

- Heating source (hot water station/steam)

- Cooling source - ice water station

- A control system with the desired degree of automation according to the customer's request

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 250l/ 500l

- Voltage: 380-400V

- Heat transfer area, m┬▓: 2,7/ 5,4/