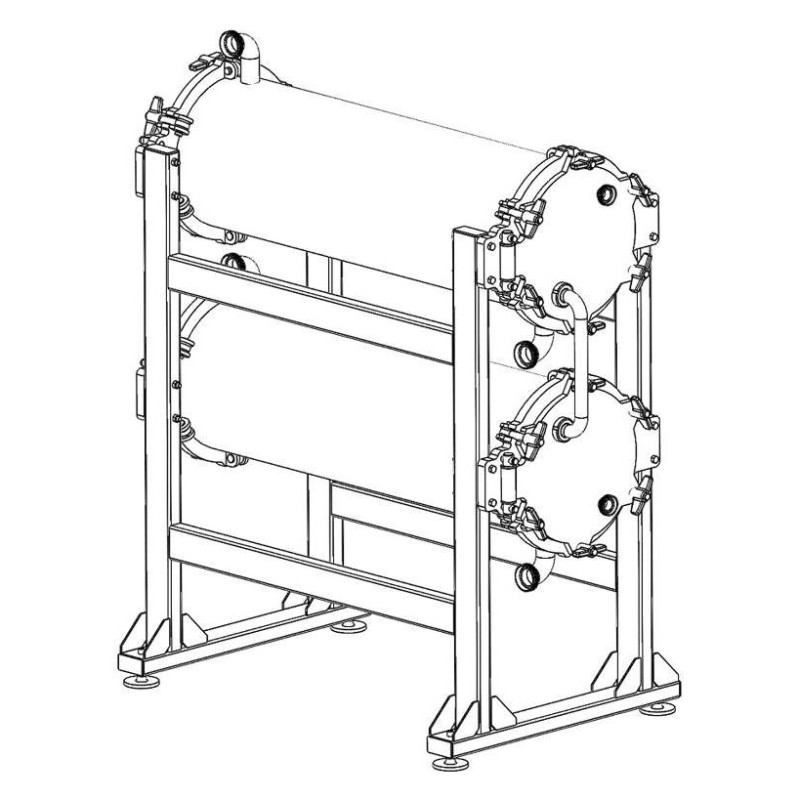

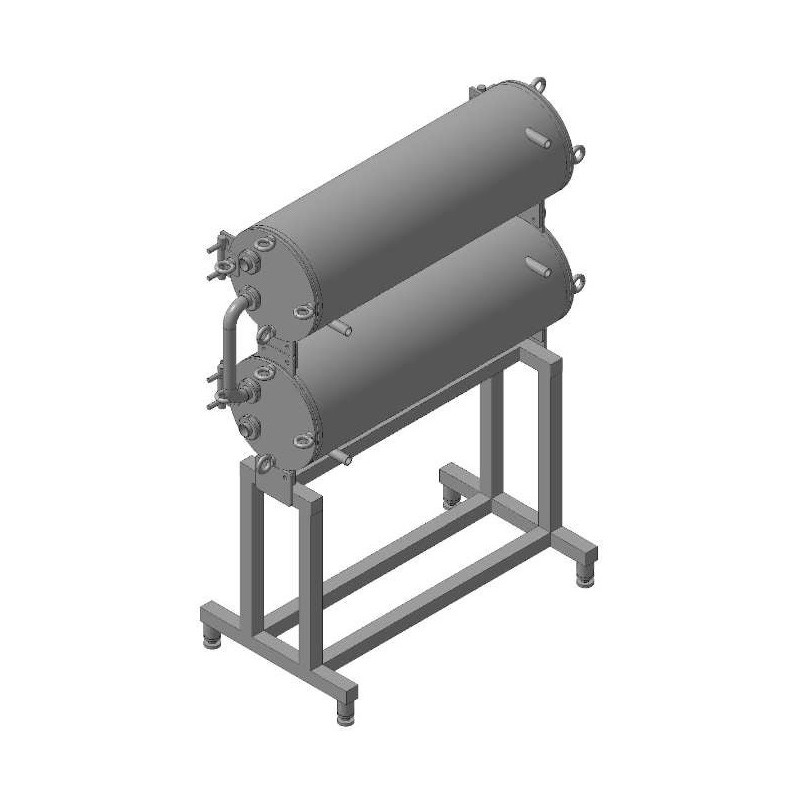

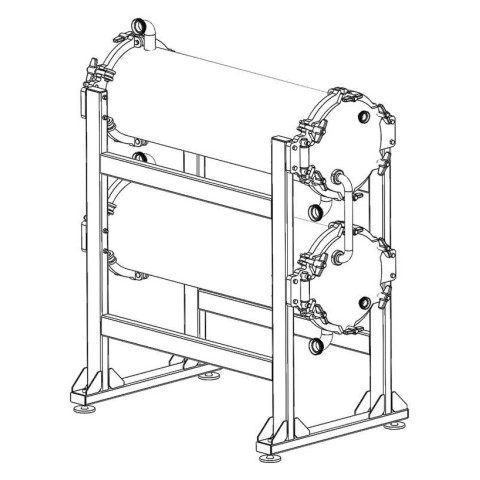

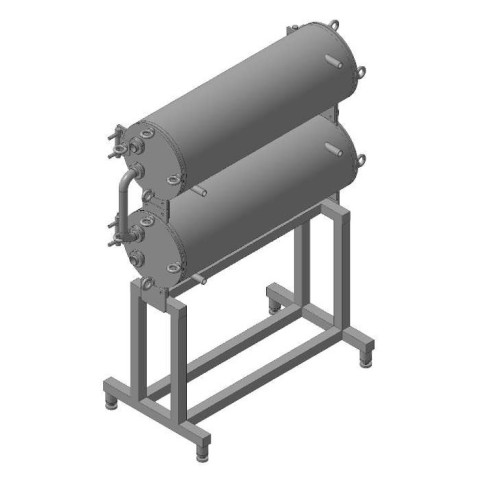

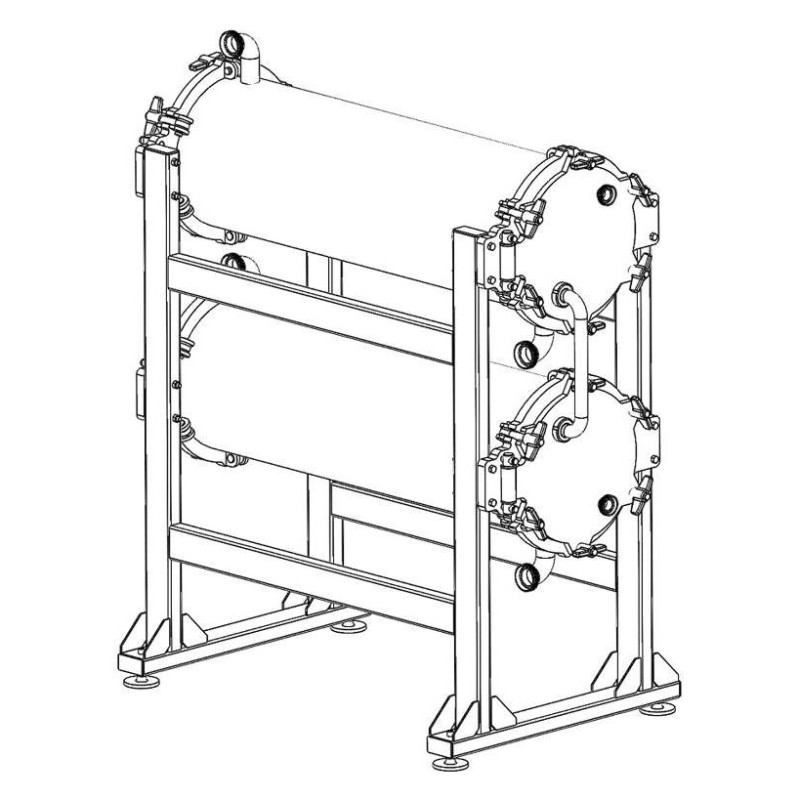

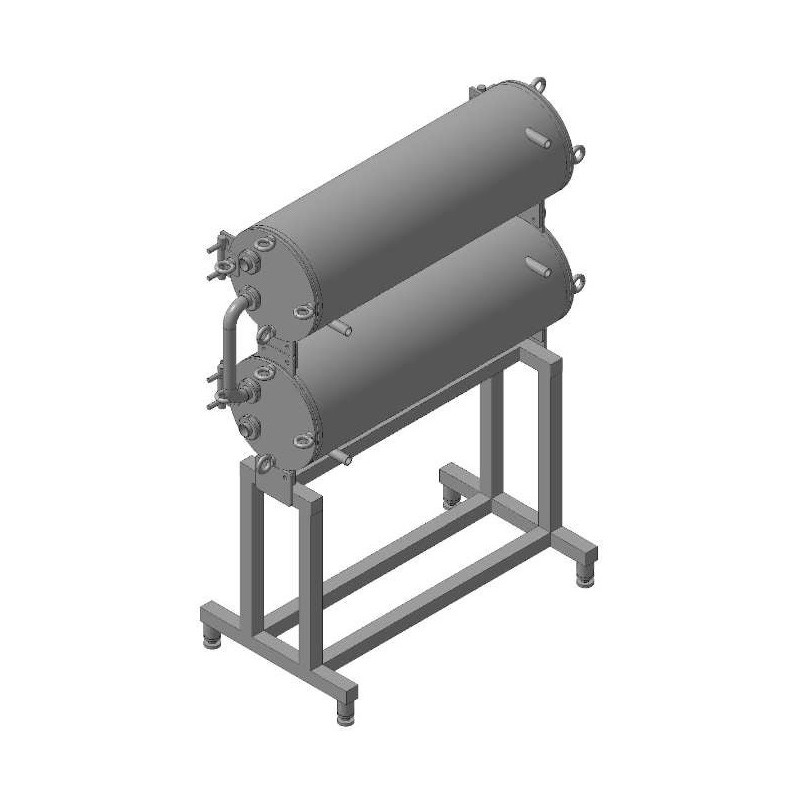

Tubular type universal pasteurizer

The tubular pasteurizer is typically designed for pasteurizing cream in butter production lines. These pasteurizers are commonly used in dairy processing industrial facilities, especially in butter production and other related sectors.

Tubular pasteurizers are extensively utilized in the food industry for the thermal treatment of various products.

They have many advantages and a wide range of applications, which makes them popular among food manufacturers. Here are some of the properties that make the tube pasteurizer a valuable solution:

- Efficient Heat Exchange - the tubular pasteurizer provides highly efficient heat exchange between the product and the heat transfer medium (usually hot water or steam), which allows you to quickly reach the required temperature for pasteurization.

- Suitable for different products - due to its design, the tube pasteurizer is suitable for processing products of different viscosities and solids content. This makes it versatile and applicable in various sectors of the food industry.

- Nutrient Preservation - the tube pasteurizer ensures that the product is heated gently and evenly, which helps preserve its nutrients, vitamins and original taste.

- Flexible settings - the tube pasteurizer allows you to easily adjust the pasteurization temperature and time depending on the specific product, providing optimal processing conditions.

- Compact design - tubular pasteurizers have a compact design, which saves space on the production site and simplifies their integration into the production line.

- Ease of service - the equipment can be easily disassembled for cleaning and maintenance, resulting in a long service life and efficient operation.

- Economic benefit - the tubular pasteurizer has relatively low operating costs and provides high performance, making it a cost effective solution for manufacturing plants.

The list of products that can be pasteurized on this type of pasteurizer is impressive, the most popular products processed on this type of pasteurizer are:

Dairy products:

- Cream

- Yogurt

- Cottage cheese

- Fats and oils

Fruit and vegetable juices:

- Orange juice

- Apple juice

- Grape juice

- Other fruit and vegetable juices

Baby food:

- Fruit and vegetable puree

- Infant formula (baby porridge)

Alcoholic drinks:

- Beer

- Wine

- Cider

Sauces and soups:

- Tomato soup

- Vegetable soup

- Pasta Sauce

- Salad dressings

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

You might also like

The price is indicated without the control unit

The heat exchanger is designed for efficient and gentle heat treatment: heating and cooling liquid and pasty products, including those with a high viscosity, such as jam, chocolate, caramel, glazes, creams, marinades, baby food, honey, fish or meat stuffing and many similar products.

- Uniform thermal processing of thick and viscous products thanks to the supply of the coolant into the duplicator

- Efficient heat transfer due to especially shaped blades

- Continuous operation that does not allow the product to locally overheat or overcool

- Intensive heat transfer due to the internal mixing of the product with scrapers

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 250l/ 500l

- Voltage: 380-400V

- Heat transfer area, m┬▓: 2,7/ 5,4/

We offer many different types of pasteurizers.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

The plate pasteurizer is designed for partial decrystallization and pasteurization of honey preheated to a temperature of 30-35 degrees.

- Principle of operation: Continuous mode

- Country of origin: EU

The price is indicated with a semi-automatic control panel

The vacuum cooking kettle is designed for use in public catering establishments (restaurants, hotels, catering companies) and small manufacturing businesses. This equipment enables boiling, blanching, frying, evaporation, pasteurization, mixing or stirring.

- A unique multifunctional device

- Possibility to cook/fry under atmospheric or vacuum conditions

- Laboratory version of a Vacuum Fryer

- Built-in condensation and secondary steam removal system

- Intense electric heating

- Sectional basket with a lid

- Built-in system for separating and removing excess liquid from the product

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Volume: 20l

- Oil volume: 8l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

We offer different types of dairy pasteurizers. Tell us if you are producing cheese, milk, yoghurt or ice cream and we will help you pick the right pasteurizer for you.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

- Volume: 200l/ 300l/ 500 l/ 800 l / 1000l

A 15-liter pasteurizer with a water bath that has a flat bottom and two canning racks, featuring a large capacity and made out of food grade 304 stainless steel.

- Material: Stainless steel

- Principle of operation: Batch mode

Electric pasteurizer suitable for pasteurizing beverages as well as filling up bottles or bag-in-boxes. We offer 3 production capacities. The basic pasteurizer model comes without the manual BiB filler module.

- Productivity: 180 l/h / 300l

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 380-400V

The electric pasteurizer is ideal for the heat treatment of various fruits, including apples, pears, blackberries, strawberries, blueberries, elderberries, currants, carrots, greens, quince, beets, sea buckthorn, rowan berries, and onions.

- Material: Stainless steel

- Principle of operation: Continuous mode

The pasteurization kettle with manual tilting is a modern device designed for gentle heat treatment of milk and dairy products, which allows for their effective pasteurization, extends shelf life and increases safety, while preserving the original taste and nutritional values. The 6-stage heating regulation of the powerful integrated heater, allows the milk to be reliably pasteurized directly in the container with a sandwich bottom, ensuring even heat distribution.

- Ideal solution for small-scale and home production of dairy products

- Removable lid for easy inspection and manual mixing of the product

- Option to equip it with a drain valve for discharging liquid products

- Even heating without burning thanks to the sandwich bottom

- Easy connection to a single-phase 230 V power supply

- Material: Stainless steel

- Heating power, kW: 6,5

- Volume: 50l/ 100l

- Voltage: 380-400V

Pasteurizer, cheese boiler is designed for processing milk, yogurt, fruit juice or other liquids.┬Ā

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24

- Volume: 200l/ 300l/ 500l

Pasteurization dipping tub is suitable for the heat treatment of packaged fruit preparations, (jams, fillings, hams) or fermented preparations (vinegar, beer) and pickles to preserve them, and to eliminate harmful microorganisms.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 200l/ 300l

The multifunctional cooking and pasteurization kettle with manual tilting is a simple device designed for the entire jam production process: from cooking the fruit mixture to the subsequent pasteurization of finished products directly in jars. It allows you to prepare the product in a container and then, using an additional basket, pasteurize the filled jars without the need for any additional equipment.

- 6-stage regulation of the built-in heating allows you to set the optimal conditions for cooking the fruits and subsequent pasteurization without the risk of burning or loss of quality.

- The manual tilting mechanism with a three-stage adjustment and a maximum tilt angle of 110┬░ ensures convenient emptying of the container and dosing of the finished product with virtually no losses.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 2,6 / 6,5

- Volume: 50l/ 100l

The professional yogurt making machine is designed to produce a wide range of yogurt production, e.g. creamy, liquid drinking, greek, white, organic, fruit yogurts. The machine can be used by farms and small dairy factories.

- Material: Stainless steel

- Principle of operation: Batch mode

This multifunctional cooking machine is designed to be used in a variety of different ways and is suitable for the majority of professional kitchens and catering businesses - any small enterprise or any participant of the HoReCa market. With the help of this equipment, you can cook, pasteurize, or blanch.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Voltage: 380-400V

We offer many different types of pasteurizers.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

Unbeatable price, excellent cooking results, designed to be placed in tight spaces where sharp edges or corners may create problems. We have different capacities boiling cookers.

- Material: Stainless steel

- Heating power, kW: 18

- Volume: 150l

- Voltage: 380-400V

Tell us if you are producing cheese, milk, yoghurt or ice cream. The difference between the milk pasteurizer and the yoghurt pasteurizer is that the yoghurt pasteurizer is equipped with a detachable arm with a detachable big stirrer and two half lids.

- Material: Stainless steel

- Country of origin: EU

- Volume: 50l/ 100l/ 200l/ 300l/ 400l/ 500 l/ 650l 800 l / 1000l/ 1250l/ 1500l

The cheese boiler is used in the dairy industry for the production of cheese grains during the production of natural hard, semi-hard, soft cheeses, and other cheese or curd products. The cheese maker is equipped with a special knife-mixer (lyre) for cutting the cheese curd. Suitable for both small and large scale production. Using this cheese-cooking boiler you can also pasteurize other dairy products, produce yogurt, cottage cheese kefir, fermented baked milk, varenets, sour cream and more.

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 300 l

A milk pasteurizer is designed for quick and effective pasteurization of milk, where the heating of the product in the working container is achieved by supplying hot water into the jacket.

- Special mixing device

- Large outlet valve at the lowest point of the pasteurizer

- Insulation of the working container to reduce heat loss during pasteurization

- Compact installation

- The control panel is located directly on the unit's body

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 300l