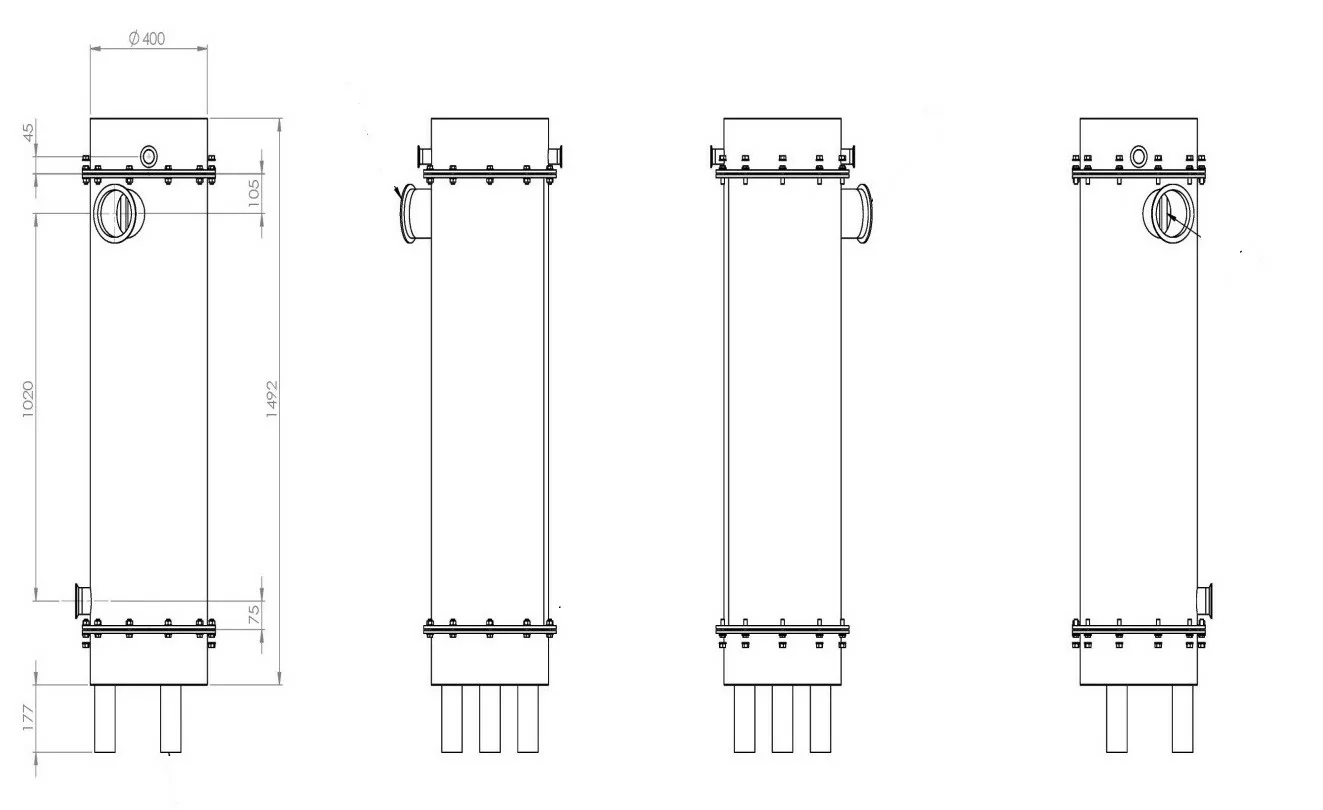

Shell-and-tube heat exchanger Heatex Tube V6

Ōé¼0.00

Vertical shell and tube heat exchanger is designed to heat and cool such viscous/pasty products as sauces, mayonnaise, creams yogurts, jams, caramel, baby food, honey etc.┬Ā

Shell-and-tube or tabular heat exchanger is designed for heating and cooling of liquid and pasty products, including those with a high viscosity.

The improvement in heat transfer efficiency is achieved by increasing the heat input rate of the heating medium or coolant into the housing. Rotor speed can vary to achieve the desired product quality and quantity.

The heat exchanger can be integrated into any production line and in any process and allows the required process to be carried out quickly, efficiently, and very hygienically.┬Ā

Processes:

- heating

- aseptic cooling

- deep cooling

- freezing

- crystallization

- dissolution

- sterilization

- polymerization

Products:

- fat-based fillings

- margarine and spreads (crystallization or re-melting)

- marinades

- sauces

- mayonnaise

- processed cheese and yogurts

- fish and meat fillings and p├ót├®s

- marmalades

- jams

- peanut butter

- gels

- syrups

- chocolate

- caramel

- coatings

- cream

- honey

- baby food and other products

┬Ā ┬Ā┬Ā

┬Ā ┬Ā┬Ā ┬Ā┬Ā ┬Ā

┬Ā┬Ā ┬Ā ┬Ā ┬Ā

┬Ā ┬Ā ┬Ā

┬Ā

Advantages:

- Reliability

- High efficiency

- Compactness

- Wide range of applications

- Large heat exchange area

- Does not damage the taste of the product

- Easy cleaning and maintenance

- Processing of particulate or fiber products

- No blind zones

- Can be equipped with a CIP┬Ā

- Low energy consumption

- Safe use for personnel

- Easy to integrate into a production line

- Highly efficient heat transfer process

- High-quality components used

Technical details:

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

New