Plate heat exchanger

The plate heat exchanger is designed for cooling/heating and transfer liquid products such as milk, water, juices, syrups etc.

The plate heat exchanger is a device in which heat is transferred from a hot coolant to a cold medium through plates.┬ĀThis hybrid model of a heat exchanger is a combination of perfect heat transfer and compact size.

It's designed for supplements with temperate flows such as 12 m /h (53 usg/min).

Design

The main elements of the heat exchanger are heat transfer plates made of corrosion-resistant alloys with a thickness of about 0.4-1.0 mm. In the working position, the plates are tightly pressed against each other and form slotted channels. On the front side of each plate, a rubber contour gasket is installed in special grooves to ensure the tightness of the channels.

Suitable products:

- water

- juices

- soft drinks

- syrups

- milk┬Ā

- condensed milk

- sunflower oils┬Ā

Advantages:

- sealed by gaskets┬Ā

- compact size

- perfect heat transfer

- doesn't need a support frame

- variability of materials for plate making

- allows accurate customization

Technical specification:

| Max flow rate |

12 m┬│/h (53 usg/min.) |

|

Max working pressure |

10 bar (145 psi) |

|

Max working temperature |

100┬░C (212┬░F), 115┬░C (239┬░F) on water/water applications |

|

Min working temperature |

0┬░C (32┬░F) |

|

Test pressure┬Ā |

15 bar (218 psi) |

|

Max. Number of plates |

60 |

|

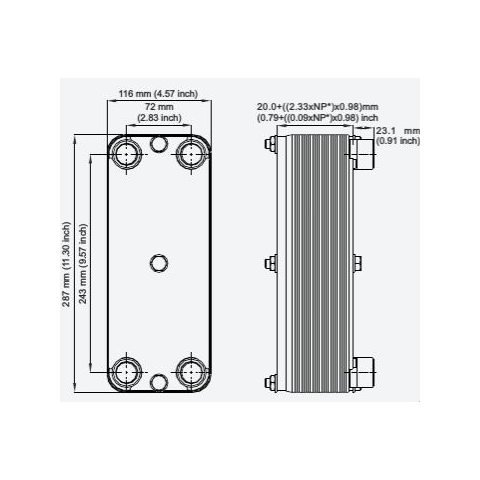

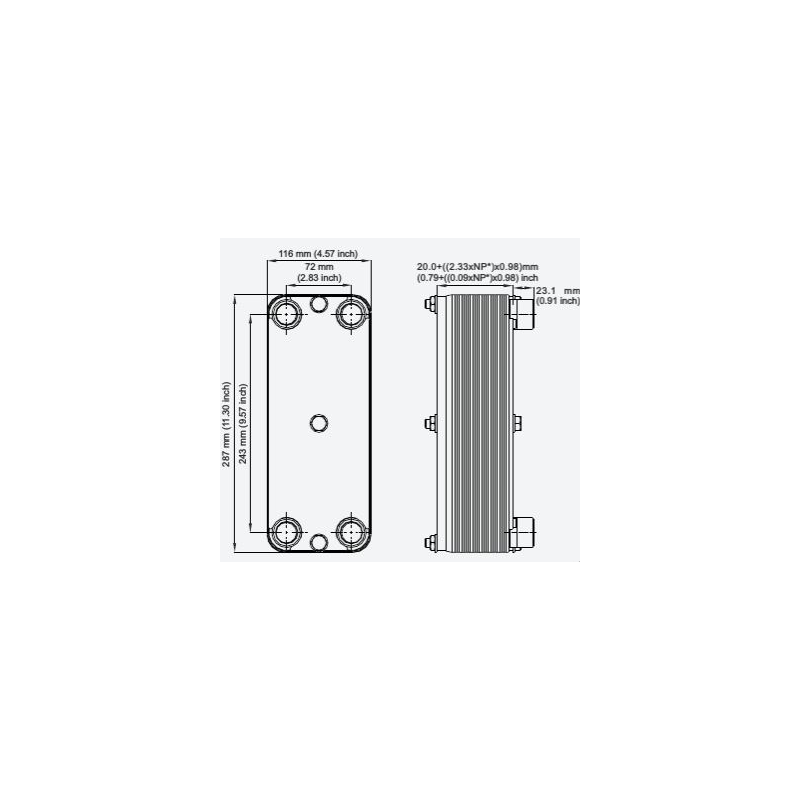

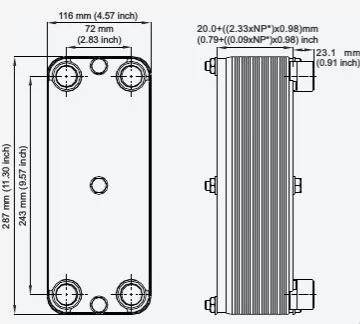

BPHE weight dry (approx.) |

6.0+0.11├ŚNP* kg (13.23+0.243├ŚNP* lb) |

|

Hold-up volume: inner circuit |

0.042├Ś(NP*/2-1) litre (0.012x(NP*/2-1) gal.) |

|

Hold-up volume: |

outer circuit 0.042├ŚNP*/2 litre (0.012xNP*/2 gal.) |

|

Standard connection size |

┬Ā1ŌĆØ |

|

Connection height |

┬Ā33 mm (1.30 inch) or 37 mm (1.46 inch) |

- Type of the equipment: Individual machine

- Country of origin: EU