Screw conveyor

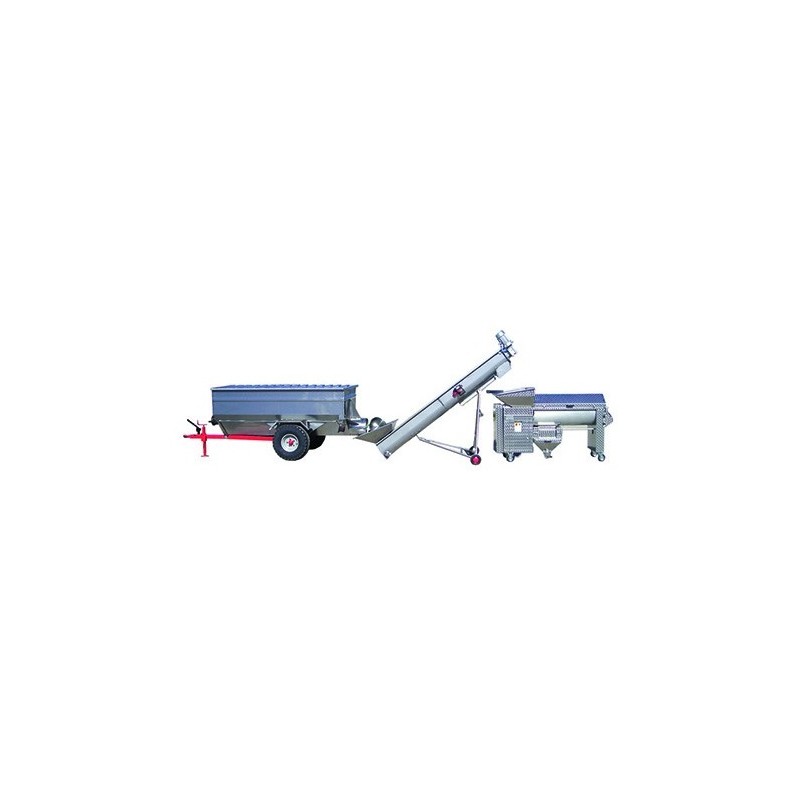

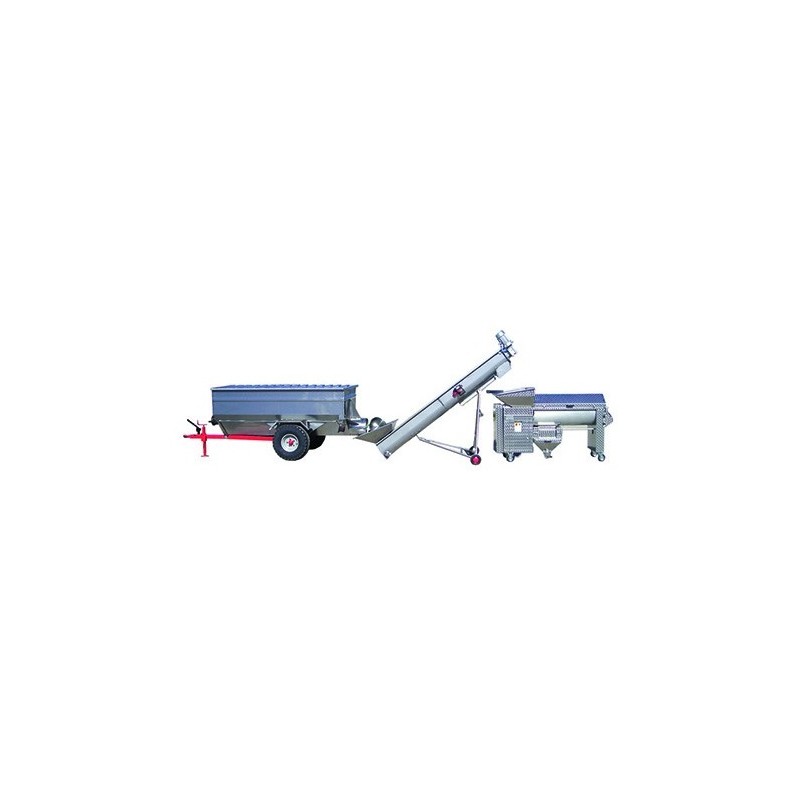

The screw elevator is intended for transporting grape marc / bagasse. It also suitable for processing olives. This type of an elevator is great for food production facilities focusing on fruit processing as well as wine and olive oil production. The machine is made in two models with 3000 and 4000 mm length.┬Ā

This screw elevator is designed to transport grape marc / bagasse and take the stalks away from the discharge area of the destemmer. The machine is made in two models with 3000 and 4000 mm length.

Thanks to the low speed of rotation the processing of the grapes goes very gently. Optionally the elevator can be equipped with a variable speed drive. It has a 1.5 kW single-phase/three-phase engine with an emergency stop EC.

The machine includes a loading hopper with pump connection for liquid drain. The elevator comes with a trolley enamelled sheet adjustable in height. Upon your request, the trolley can be made in stainless steel.

STANDARD FEATURES

- Stainless steel screw diameter ├ś 200mm, length 3,00/4,00 mt

- Loading hopper with connection fitting for liquid

- Open lid for cleaning

- Winch to adjust the height

- Smalted trolley with wheels

- Engine 380V 50Hz three-phase

- Panel control

Technical characteristics

|

Model |

Length |

Engine Hp (Kw) |

Hopper dimension | Loading length | Unloading length |

Capacity |

Weight |

|

U200-3 |

3000 mm |

2 (1,5) |

650x720x900┬Āmm |

710/480 mm |

1600/2000┬Āmm |

2-10 Ton/h |

90┬ĀKg |

|

U200-4 |

4000 mm |

2 (1,5) |

650x720x900┬Āmm |

710/480 mm |

1900/2500 mm |

2-10 Ton/h |

130┬ĀKg |

OPTIONAL

- A frequency converter

- Stainless steel trolley

- Longer hopper for macrobid use

- Productivity: 2-10 ton/h

- Engine power, kW: 1,5 KW

- Principle of operation: Continuous mode

You might also like

For a price quote or for a free consultation, send us a request.

- Productivity: 90l

- Material: Stainless steel

- Heating power, kW: 6/

- Principle of operation: Continuous mode

- Voltage: 380-400V

Pneumatic fruit presses are intended for smaller winemakers who want to produce high quality wine. Price depends on your production parameters.

- Material: Stainless steel

- Principle of operation: Continuous mode

The belt press is designed for pressing fruit or vegetable mass. Price depends on your production and product.

- Productivity: 700 kg/h 1500 kg/h/ 3000 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

This open tank is intended for washing the juice tanks. Kapacity 250L.┬ĀFor more information, send us a request.┬Ā

- Material: Stainless steel

- Volume: 250l/

Pasteurizers are used for the heat treatment (pasteurization) of juice before it is filled into bottles, containers or other types of packaging. Its compact, space-saving design and simple operation make it suitable for various production facilities.

- Productivity: 400 l

- Material: Stainless steel

- Heating power, kW: 36

- Country of origin: EU

- Voltage: 380-400V

Washing tank with wheels with conveyor belt for fruits and vegetables.

- Material: Stainless steel

- Engine power, kW: 2,4/

- Principle of operation: Continuous mode

- Country of origin: EU

- Working Area Width: 330 mm

- Voltage: 380-400V

Vibrating conveyors suitable for arranging the product before further processing.

- Working Area Width: 720 mm

- Voltage: 380-400V

CAC Air cooling conveyors are designed for intensive cooling and removal of excess water or oil (air knife section) from products after frying, cooking or blanching.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 500 mm

- Voltage: 380-400V

The conveyor is made out of strong and highly-resistant stainless steel. It is also additionally reinforced for reliability during operation.

- Material: Stainless steel

- Principle of operation: Continuous mode

Air cooling conveyor with MULTI AIR KNIFE is a system for┬Ā intensive┬Āremoving excess water or oil and preliminary cooling.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 500 mm

Variable belt conveyor with wide use not only in the food industry. The length of the conveyor can be selected from 2 to 6 m. The width of the belt is 200 and 400 mm.

- Engine power, kW: 0,75

- Principle of operation: Continuous mode

The bucket elevator is designed for transporting loose bulk materials, such as grain and seeds in a vertical position. It's an ideal solution for transporting various products for the baking industry as well as animal feed and other granular productions.

- Principle of operation: Continuous mode

The screw conveyor with heating is a device designed for the transportation of material using a screw mechanism, while heat is applied to the product to facilitate easier transfer. This type of conveyor is often used to simplify the transfer of various bulk materials.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. Price depends on the product and size of the conveyor.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: EU

The sorting and transporting table or conveyor is suitable for manually sorting and delivering products to the next processing stage.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Width: 530 mm

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. Price depends on the product and size of the conveyor.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. Price depends on the product and size of the conveyor.

- Material: Stainless steel

- Engine power, kW: 0,25

- Weight: 100

An air cooling conveyor is used to rapidly cool products in food processing industries by circulating cool air over them as they move along a conveyor belt. This efficient cooling process helps preserve product quality and reduce the time between processing stages, facilitating smoother production workflows.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

Optional module for the 400/1100/12 universal tabletop Modular Fryer - Pressure Conveyor for frying foods that require forced immersion in oil.

- Material: Stainless steel

The incline screw conveyor is used for transporting a wide range of bulk, powdery, fine-grained, and dusty products in food, chemical, construction, or agro-industries.

- Material: Stainless steel

- Engine power, kW: 0,75 1,1/ 1,5 / 2,2

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. Price depends on the product as well as size of the conveyor.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia