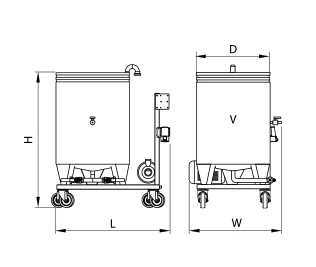

Open tank for washing juice tanks 250l

This open tank is intended for washing the juice tanks. Kapacity 250L. For more information, send us a request.

This open washing tank is intended for washing the juice tanks.

The open tank is used for the preparation of cleaning agent (water, detergent, etc.). It is equipped with a centrifugal pump, which helps to perform the washing system.

WASHING TANK - MAIN FEATURES:

- Entirely made of stainless steel.

- Total outlet at the bottom.

- Sampling cock in the middle.

- 3/4‚ÄĚ Inlet valve at the bottom.

- Return pipe.

- Centrifugal pump with switch.

- Mounted on trolley.

- Open tanks are very easy to clean

- Material: Stainless steel

- Volume: 250l/

You might also like

Clean-in-place (CIP) is a method of cleaning and disinfecting the internal surfaces of pipes, containers, water tanks as well as industrial equipment, filters, related fittings and other accessories without the need for disassembly.

- Material: Stainless steel

- Volume: 2x50 l/ 2x100 l/

The cylindrical conical tank is a designed for the fermentation of the beer and other beverages.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

The hot water tank is designed to catch the preheated water from the first stage of the wort cooling and then heat it to 80 ¬į C, the pump bowl is a part of the vessel.¬†

- Material: Stainless steel

- Type of the equipment: Individual machine

- Volume: 2000

These storage tanks are intended for fruit and vegetable juice storage and treatment. Price depends on your production process and the product.

For more information, send us a request.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 750 1000l/ 1500l 2000 2600 l/ 3000 4000 l/ 5000 l

The rotary drum cooler is designed for efficient pre-cooling, stopping the cooking process, and cooling of boiled, blanched, fried, baked, or thermally processed foods. The rotating perforated drum ensures uniform cooling together with the additional water supply.

- Uniform cooling

- Adjustable drum speed

- Made entirely out of stainless steel

- Suitable for a wide range of food products

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 1,1

Wheat washer, huller and separator is used for the preparation of grain for milling. Price depends on your production capacity.

- Productivity: 1500 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

Improve the cleaning process with the CIP-53, a mobile station designed for thorough sterilization and sanitation of vessels and pipelines. Ideal for breweries and the food industry, this comprehensive system with three 50 or 100 liter tanks ensures efficient cleaning of fermentation and storage tanks, offers digital temperature control and neutralization.

- Material: Stainless steel

- Voltage: 380-400V

- Productivity: 800 psc/h

- Material: Stainless steel

- Operation mode: Semi-automatic

Dimensions: 2000x1230x1600

Volume: 150 l

Performance: up to 3000 kg/hour

Price on request.

- Productivity: do 3000 kg

- Material: Stainless steel

- Principle of operation: Continuous mode

- Volume: 150l

- Voltage: 380-400V

- Dimensions, mm: 2000x1230x1600

Our tunnel container washers are designed to wash different kinds of plastic containers.

- Material: Stainless steel

- Heating power, kW: 15/ 20

- Principle of operation: Continuous mode

- Voltage: 380-400V

- Productivity: 300 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

The machine is used for brushing, cleaning as well as prewashing various root vegetables.

- Material: Stainless steel

- Engine power, kW: 2,2

Bubble washer for gentle washing and cleaning of fruits and berries, for example peaches, cherries, strawberries and other raw fruits prior to their further processing.

- Principle of operation: Continuous mode

- Country of origin: EU

- Working Area Width: 600 mm/ 800 mm/ 1000 mm

Vegetable washers are designed to clean and prepare vegetables for consumption or further processing.

We offer different types of vegetable washers.

- Material: Stainless steel

- Engine power, kW: 0,47 / 1,45 / 1,85

- Type of the equipment: Individual machine

- Country of origin: EU

- Volume: 160 l/ 300l/ 600l/

CIP-51: Equipment for cleaning and disinfection of vessels and pipelines in breweries and other food industries with one tank of 50 liters

- Material: Stainless steel

- Country of origin: EU

CIP station CIP-101 With a usable capacity of 1√ó100 liters, it is used for cleaning, sanitizing and sterilizing vessels and pipes in a brewery. This type of CIP station is recommended for cleaning and sanitizing tanks from 0 to 4000 liters.

- Material: Stainless steel

- Country of origin: EU

This machine is suitable for washing fresh fruits and vegetables. We offer 2 different capacities.

- Productivity: 1000 kg/h/ 3000 kg/h

- Material: Stainless steel

- Engine power, kW: 0,55/ 0,75

- Principle of operation: Continuous mode

- Voltage: 380-400V

The brush washer/scraper is an industrial device for washing and scraping root vegetables depending on the degree of contamination.

- Productivity: 300 kg/h

- Material: Stainless steel

- Engine power, kW: 1

- Voltage: 230 V/ 380-400V

CIP-202: Cleaning-In-Place - Machine for cleaning and disinfecting vessels and pipelines in breweries and other food processing plants with two 200 liter tanks.

- Material: Stainless steel

- Country of origin: EU

- Volume: 200l

Clean-in-place (CIP) is a method of cleaning and disinfecting the internal surfaces of pipes, containers, water tanks as well as industrial equipment, filters, related fittings and other accessories without the need for disassembly.

- Material: Stainless steel

- Volume: 2x50 l/ 2x100 l/