Fillers have been designed and constructed to supply any kind of product in the following industries: food, chemical, pharmaceutical and cosmetic industry.

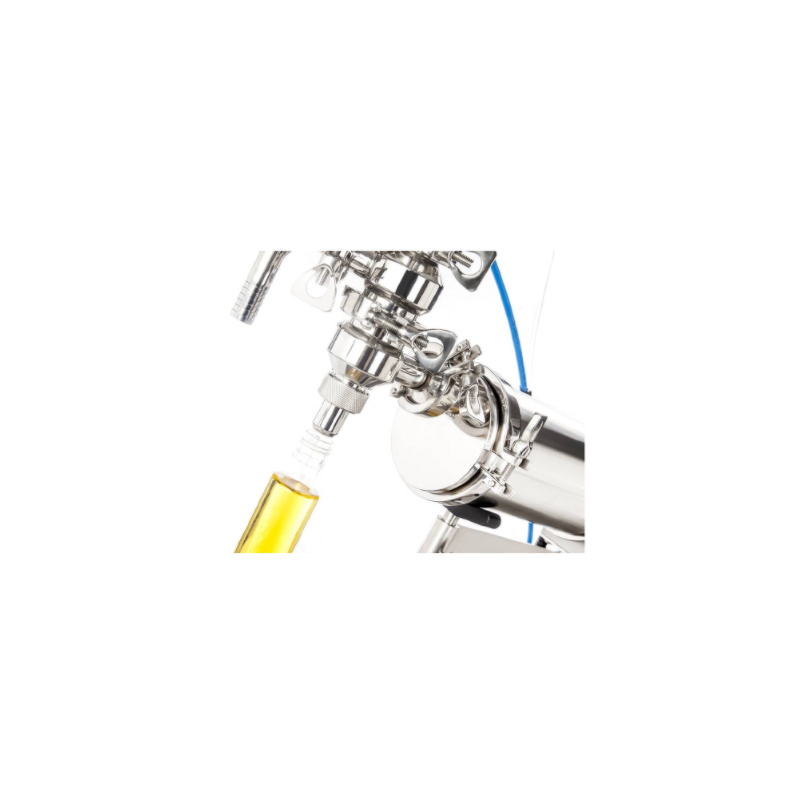

The product is introduced through the suction system into the dosing chamber. Once the desired amount has been reached, the piston begins to push the product out through the outlet valve and nozzle.

Depending on the product in which the chamber is filled, different valves can be changed on the machine. On the back of the filler there is a manual control wheel that determines the volume of the product, for this model the range is between 50 and 1300 ml. O-rings and gaskets are manufactured in food grade PTFE and silicone for food products or in PTFE S / steel, FKM or, EPDM for chemicals and cosmetics. All other parts in contact with the product are made of AISI 316 L with stainless steel.

All joints are equipped with a triple clamp as they are used in the pharmaceutical industry. For this reason, the operator does not need any tool for dismantling the cleaner or technical inspection. The sieve and dosing speed can be controlled by 2 air regulators. All our machines are CE certified

The machine is completely pneumatic and needs compressed air 6 bar (we also recommend 80/100 liters air compressor)

Available models and filling ranges:

- 0-38 ml

- 2-100 ml

- 2-260 ml

- 20-680 ml

- 50-1300 ml

- 200-5000 ml

- Material: Stainless steel

- Operation mode: Manual

- Type of the equipment: Individual machine

You might also like

Semi automatic packaging machine for filling and capping jars.

- Material: Stainless steel

4 Heads vacuum bottle filling machine serves as a professional semi-automatic filling and dosing machine for filling glass bottles with various fluids.

- Material: Stainless steel

- Operation mode: Manual

- Type of the equipment: Individual machine

Semi-automatic dosing machine, designed for filling and capping different spouted pouches with various liquids.

- Material: Stainless steel

- Operation mode: Semi-automatic

The piston-operated pneumatic liquid dispenser is a semi-automatic filler used for dispensing various low viscosity liquids ranging from 10 to 100 ml in volume.

- Compact tabletop installation

- Simple control with two operating modes: manual and semi-automatic

- Suitable for liquid products with low viscosity (from water to oil)

- Optional compressed air compressor available

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Continuous mode

- Voltage: 220-230V

The manual bottle filler is designed to fill liquids in glass bottles.┬Ā

- Productivity: 650 psc/h

- Material: Stainless steel

- Operation mode: Manual

We sell many different filling machines for different products.

- Material: Stainless steel

- Country of origin: EU

Filling machine is designed for pumping and filling high viscosity liquids, such as jams, confiture, sauces, dressings, syrups, and like products.

- Productivity: 200ŌĆō600 bottles per hour

- Material: Stainless steel

- Principle of operation: Continuous mode

Automatic Bag-in-Box filler intended for filling the bag-in-box bags with finished products (both hot and cold) - with a bag volume of 3 to 20 liters.

- Productivity: 180 -240 psc/h

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Continuous mode

- Voltage: 220-230V

The device is designed for filling Bags In Boxes. Suitable for filling hot non-viscous products. The device can be purchased separately or with additional options - trolley and magazine.

- Material: Stainless steel

- Operation mode: Automatic

This semi-automatic filling machine is used for filling honey as well as other products. We offer many different kinds of filling machines for different applications.

- Material: Stainless steel

- Operation mode: Semi-automatic

We offer different types of meat stuffing machine for domestic and commercial use.

- Weight: 10 / 12

- Dimensions, mm: 630 x220x230 / 820x220/230

Compact digital filling machine for accurate dosing of viscous liquids such as honey, pastes, sauces, and oils. Designed with food-grade materials, easy-to-clean components, and precise digital control, it is ideal for small production, workshops, and laboratories.

- Operation mode: Semi-automatic

The honey dosing machine is a precise filling machine with a gear pump, it is easy to use and is suitable for filling honey as well as a large number of other different liquids - ranging from thinner ones such as drinking yogurt, to high-viscosity products such as mustard.

- Fast operation

- Easy to use

- Easy to clean

- Accuracy

- Compact design

- Productivity: 200 l

Normit AP tensometric filling machine is a weight-based system for filling honey into barrels.┬Ā

- Material: Stainless steel

- Country of origin: Slovakia

The pneumatic piston filler for pastes and liquids is a semi-automatic dispenser designed for dosing various liquids with a low, medium or high viscosity.

- Tabletop compact model

- Includes a built-in 26 l conical storage tank

- A wide dosing range from 300-2500 ml

- Can also be used for products with a high degree of viscosity

- High dosing speed

- Possibility of working in manual or automatic mode

- Material: Stainless steel

- Principle of operation: Continuous mode

- Volume: 300-2500 ml

- Voltage: 220-230V

We offer different types of sausage filling and stuffing machines. This version is a simple tabletop filling device with hydraulic filling.

- Material: Stainless steel

- Engine power, kW: 0,18/

- Country of origin: EU

- Weight: 46

- Volume: 15 l

- Dimensions, mm: 320 x400x1260

Filling and capping machine designed for the filling and capping of liquid or semi-liquid products into flexible doypack bags with a spout.

- Material: Stainless steel

- Voltage: 220-230V

A range of pneumatic vertical filling machines for dosing liquids with viscosity is similar to water.

- Type of the equipment: Individual machine

Designed for accurate feeding and packaging of liquids under pressure.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 80l/

Dosing tank for filling and measuring oil designed as an oil reservoir with the ability to adjust the required volume.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l

- Working volume: 80 l