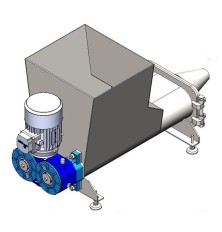

The forming device works on the rotary principle - however, the hopper is emptied 4 times faster than in conventional rotary molding machines.

The machine is optionally supplied with an automatic wire cleaning and cooling system - due to the fact that the system operates at 3000 rpm.

All contact surfaces are made of materials suitable for use in the food industry. The model is equipped with three safety elements for locking the device, so that you ensure safe operation.

The hopper, forming drum and conveyor are removable for easy cleaning.

Features

- Floor standing

- Easy to clean

- Easy to maintain

- Chilling system in the top to reduce product temperature rise

Specification

- Number of drums: 2

- Hopper, L: 200 - sealed┬Ā

- Hopper: 3 mm Stainless steel

- Paddle: 6mm Stainless steel - up to 5 time stronger than other rotary formers 250 nm against 50 nm

- Motor, kW: 1,5 with variable speed

Special attribute

A combination of different drum surface finishes and paddle configuration ensure possibility to make different form. Not only burger but also to produce and a range of vegetarian and ethnic food products i.e. Falafel, Aloo Tikki, Pakora and onion bhaji the Formatic On the machine you can also achieved equal success forming cookies, shortbread or novelty biscuits, Flapjack, health food bars and Xmas puddings in the bakery industry as well as Butter portions for the catering and ready meals industry

- Material: Stainless steel

- Principle of operation: Continuous mode

You might also like

The mixer is designed for mixing large quantities of dough as well as meat mixtures.┬Ā

- Material: Stainless steel

- Engine power, kW: 1,5 / 2,2

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 80l/ 140l

- Voltage: 380-400V

The hamburger production line is designed for the production of hamburgers, veggie burgers or soy-based burgers. The line produces from 2.000 up to 6.000 hamburgers per hour. Price depends on the production requirements.

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

- Voltage: 220-230V

Meatball production line comprises of a filler, automatic machine for making meatballs and batter-breading machine. Price depends on your production capacity.

- Productivity: 15 000

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 220-230V

The machine is suitable for forming minced meat, poultry, fish, potato and vegetarian, vegan patties. The price depends on your product specifics and production capacity.

- Productivity: 800 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 600 mm

- Voltage: 380-400V

Rotary molding machine for confectionery products: candies from paste-like masses, crushed fruit masses, protein candies and bars. Specially designed for molding candies from food masses.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 1,5

- Voltage: 380-400V

This cookie making machine is designed to produce an unlimited variety of cookies, cakes, and other pastry snacks. We offer five different types of cookie depositing machines, each tailored to various cookie types

- Engine power, kW: 2,4/ 2,5/ 3,3 3/

- Principle of operation: Continuous mode

- Voltage: 220-230V

The screw pump is used for transferring "un-pumpable" products. A great choice for those who work with hard to move liquids and need to move them as quickly as possible.

- Material: Stainless steel

- Voltage: 380-400V

The forming device guarantees accurate forming of a wide range of food mixtures. The FR 75 is suitable for various mixtures of different textures and consistencies.

Semi-automatic tying machines are designed for tying sausages and other meat products. Suitable for meat producers or small butchers.┬Ā

- Material: Stainless steel

- Weight: 42

This ground-breaking device allows for constant fine tuning of the roundness of the boilies thanks to its PLC control device. It is sold in two versions. The price depends on the options you choose.

We also offer a extruding machine suitable for this boilie machine.

- Material: Stainless steel

- Principle of operation: Continuous mode

The hamburger production line is designed for the production of hamburgers, veggie burgers or soy-based burgers. The line produces from 2.000 up to 6.000 hamburgers per hour. Price depends on the production requirements.

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

- Voltage: 220-230V

Twin-screw extruder is designed for effective extruding, homogenization, pumping over of plastic masses (butter, margarine, honey, curd products, confectionery mixtures), and forming it into bars and rolls.

- Productivity: 400 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Weight: 115 kg

Create natural shapes of nuggets, pieces that have the appearance of a "hand-formed" product.

- Material: Stainless steel

An automatic forming machine shapes food mixtures such as ground meat or plant-based alternatives into uniform portions. It automates portioning and shaping, and can also add a separation paper for easier handling before transferring the products with a conveyor. These machines reduce manual labor and increase output capacity for food processing facilities, butcher shops, and commercial kitchens.

- Material: Stainless steel

- Principle of operation: Continuous mode

SIPM 10 liter pasta mixer is designed for medium size commercial operations, ideal for medium-size restaurants to produce any kind of pasta such as spaghetti, taglia pasta, cannelloni, macaroni, conchiglie, rigatoni, penne and many others. The price includes a pasta cutter.

- Productivity: 8,4 kg/h

- Material: Stainless steel

- Engine power, kW: 0,75

Fully automatic machine for making kebab and brochettes by skewering meat on a stick with a maximum production capacity of 1500 pieces per hour.

- Productivity: 1500 psc/h

- Principle of operation: Continuous mode

- Weight: 120

- Voltage: 220-230V

The burger forming machine is a reliable solution for small to medium-scale food production. Burger formers are designed to automate the patty-making process, they ensure consistency in shape, size, and weight, making them ideal for restaurants, butcher shops, and small food processing businesses.

- Material: Stainless steel

- Principle of operation: Continuous mode

Croquettes production line for making and batter breading croquettes, preparing them for frying. Croquettes from 15 to 55 grams. Produces up to 12,000 pieces/hour. We also offer a range of fryers.

Price depends on your production capacity.

- Productivity: 12 000

- Material: Stainless steel

- Principle of operation: Continuous mode

Rotary molding machine for confectionery products: candies from paste-like masses, crushed fruit masses, protein candies and bars. Specially designed for molding candies from food masses.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 1,5

- Voltage: 380-400V

The machine is suitable for forming minced meat, poultry, fish, potato and vegetarian, vegan patties. The price depends on your product specifics and production capacity.

- Productivity: 800 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 600 mm

- Voltage: 380-400V