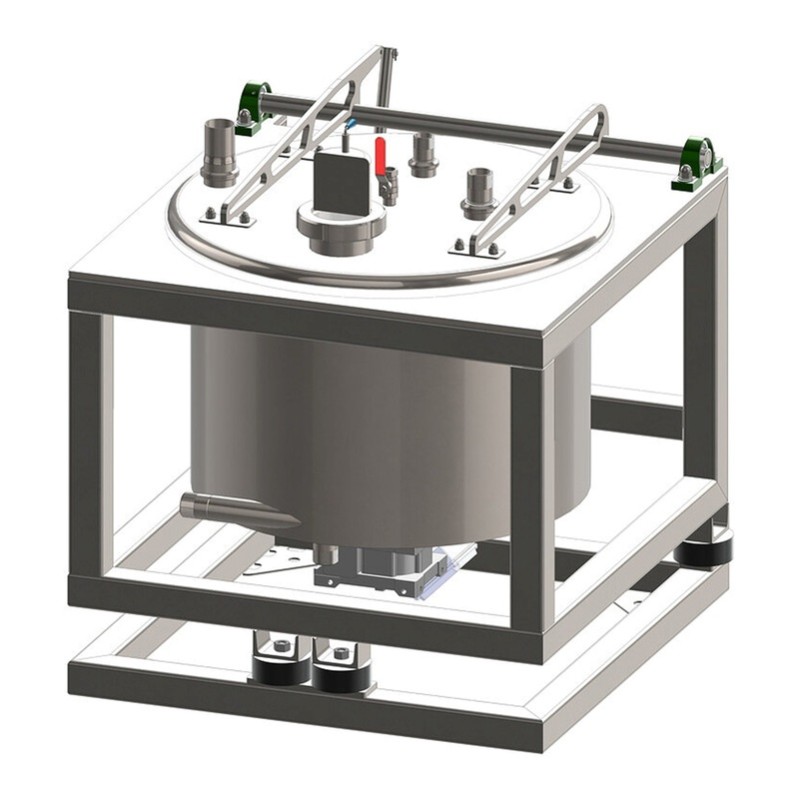

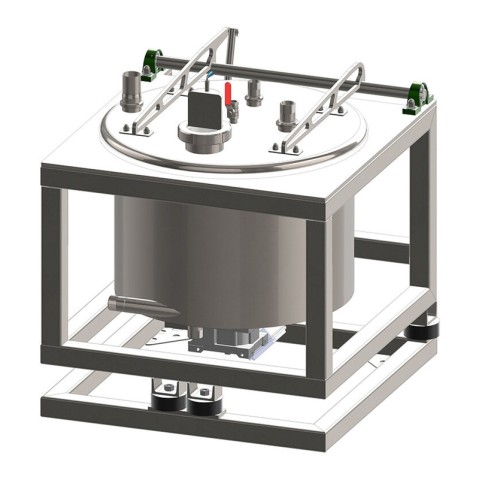

This separating installation allows you to perform the following functions:

- Pre-washing

- Washing

- Filtration

The principle of operation is based on the ability of the equipment to dissolve crushed electrolyte in a special basket by supplying special solutions. The equipment also makes it possible to wash the precious metals in the basket and filter them out by centrifugal force.

The technological process can depend on the specific product as well as the processing technology.

The product is loaded into the basket through the installation hatch above. The working fluid is fed from above and at an angle for better distribution and atomization of the working fluid, the outlet is equipped with a tangential outlet for fast and intensive draining of the working fluid while the working basket is rotating.

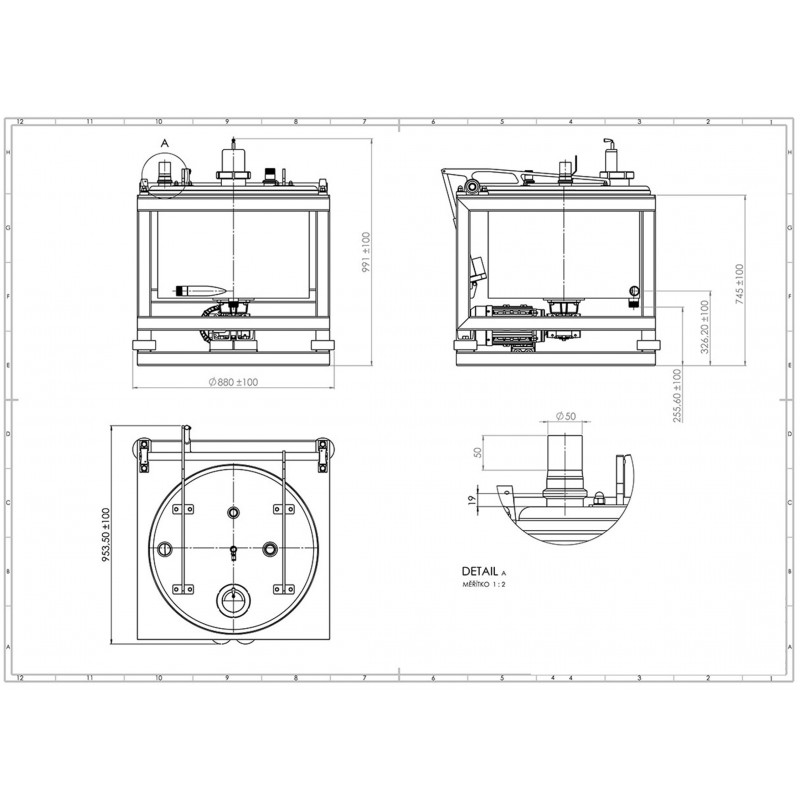

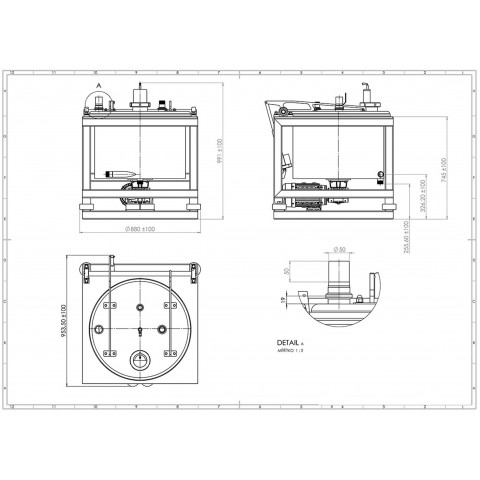

The system's technical parameters:

| Volume - working capacity, l | 150 |

| Basket working volume, l | 20/80 |

| Centrifugal unit drive - power, kW | 2,2 |

| Maximum load, kg | 15 |

| Rotation speed, rpm | 580 |

| Dimensions (H/L/W), mm | 991/954/880 |

| Weight, kg | 220 |

| Material* | AISI316/304 |

The imensions of connections and the outlet for the working fluid, DN 32

Three-phase power supply:

| Voltage, Volt | 400 |

| Frequency, Hertz | 50 |

Additional options:

- CIP wash heads to choose from (regular or rotary)

- Material: Stainless steel

- Engine power, kW: 2,2

- Volume: 150l

- Voltage: 380-400V

You might also like

The destoner lift machine is designed for pre-washing and transporting root vegetables such as potatoes, carrots, beets, and other similar vegetables. After rinsing, the auger destoner separates floating particles like leaves and stems in the receiving hopper, while the product is conveyed up to the discharge height using a screw lift.

- Allows you to separate stones, leaves from root vegetables

- Pre-washing of root vegetable crops

- Two functions in one unit: washing and transporting

- Spacious hopper/tub for loading the product

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The machine is used for brushing, cleaning as well as prewashing various root vegetables.

- Material: Stainless steel

- Engine power, kW: 2,2

Fruit washer is designed for washing and cleaning products such as fruit or vegetables before processing, especially apples.

If you're looking for any other fruit and vegetable washers, send us a request.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

The washer-elevator-mill machine is designed for washing, transporting and milling whole fruit or vegetable before further processing.

- Productivity: 1000 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

This machine is suitable for washing fresh fruits and vegetables. We offer 2 different capacities.

- Productivity: 1000 kg/h/ 3000 kg/h

- Material: Stainless steel

- Engine power, kW: 0,55/ 0,75

- Principle of operation: Continuous mode

- Voltage: 380-400V

Essential oil distiller with a volume of 130l. It is used for distilling essential oils from different types of plants.

- Material: Stainless steel

- Engine power, kW: 0,55

- Heating power, kW: 9/

- Volume: 130l

- Voltage: 380-400V

Flow type magnetic separator for liquid mixtures with a manual cleaning.

- Material: Stainless steel

- Country of origin: Slovakia

The semi-closed separator for purification, normalization and separation of whole milk into cream and skim milk.┬Ā

- Engine power, kW: 2,2

- Principle of operation: Continuous mode

The equipment is designed for centrifuging and separating different types of products and raw materials.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

The vegetable spin dryer has been designed for drying leafy vegetables rapidly and efficiently, both raw and boiled, prepared in medium-large sized professional kitchens and in food industries.

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Batch mode

- Voltage: 220-230V

Fast, sleek, quiet, user-friendly, safe, smooth-running commercial salad dryer, designed to efficiently dry up to 6 Kg.

- Engine power, kW: 0,55

- Principle of operation: Batch mode

For caterers it is very important to dry any kind of vegetable within a few seconds, keeping unaltered the natural freshness and without damaging the most delicate leaves. We offer 3 different capacities.

- Material: Stainless steel

- Engine power, kW: 0,37/ 1,1

- Principle of operation: Batch mode

- Country of origin: EU

- Weight: 56/ 100

- Voltage: 230 V/ 380-400V

An open-type cream separator with a capacity of 1,000 l/h is designed for continuous separation of whole milk into cream and skim milk. The separator allows the purification of milk from impurities and milk mucus.

- Productivity: 1000 l

- Engine power, kW: 0,55

- Principle of operation: Continuous mode

- Weight: 71

- Voltage: 380-400V

Used for blanching products in water, it is suitable for processing various vegetables, legumes, grains, mushrooms and other products. This versatile machine also functions as a water separator centrifuge which is activated after the blanching processes.

- Productivity: 30l/ 90l

- Material: Stainless steel