Flow type magnetic separator SMP

Flow type magnetic separator for liquid mixtures with a manual cleaning.

Flow type magnetic separator

Magnetic separators SMP are flow-type separators (so called ŌĆ×magnetic filtersŌĆ£) characterized by manual cleaning. They are the most common types of separators used in separation of magnetic impurities in liquid mixtures and liquids transported in the industrial pipeline systems in discontinuous operations.

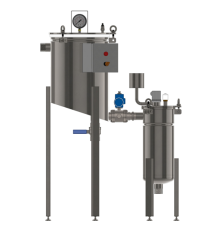

Separated medium flows through the separator, either using a free flow without a pressure, or based on a forced flow in a pressure pipeline. SMP separators are designed for both vertical and horizontal pipeline directions. SMP separator design system is characterized by closed magnetic cores in the covering pipes. This way the protection of magnetic cores against negative action of aggressive environments is provided.

In general, SMP magnetic separators are suitable for using in all industrial areas where the cleaning medium is a liquid or, respectively, liquid material mixtures with common flowing parameters.

Applications

- Liquid cooling systems in all industrial areas,

- Machine engineering, ceramics and porcelain industry, chemical industry,

- Food industry ŌĆō liquid products and intermediate products,

Separation aimed at technological protection in operations

Separation aimed at technological protection is focused on removing of ferromagnetic impurities from a medium, purposed at a protection of technological devices (pumps, filters, etc.) against their damaging. The separator is situated already within the medium processing, namely before the technological units that need to be protected against damaging and/or wear and tear by Fe particles. From the output point of view, grate magnetic cores are equipped with strong NdFeB magnets, and their composition (or, in other words, core assembly, is made to catch medium-size, fine to smaller impurities (from the size of 1.0 mm) that could damage subsequent technological devices.

Separation aimed at the product cleanliness┬Ā

This separation is aimed at the own product cleaning from the ferromagnetic impurities, focused on achieving as good as possible product cleanliness. In this case, the separator is situated especially in the end of the manufacturing process, or within its course, on more places. This is the most efficient technique. . From the output point of view, grate magnetic cores are equipped with strong NdFeB magnets, and the magnetic core composition is made to catch medium-size, fine to smaller impurities (from the size of 1.0 mm).

Flow-type separator: design and functioning┬Ā

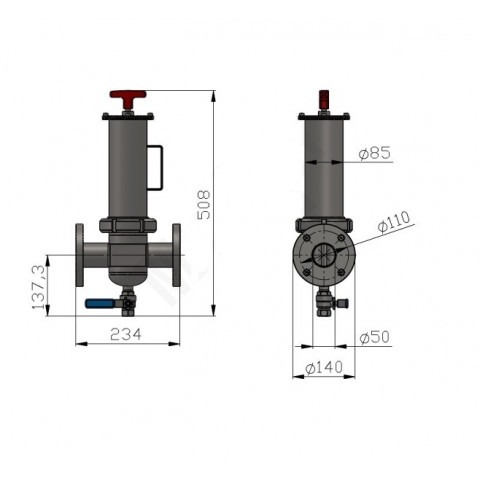

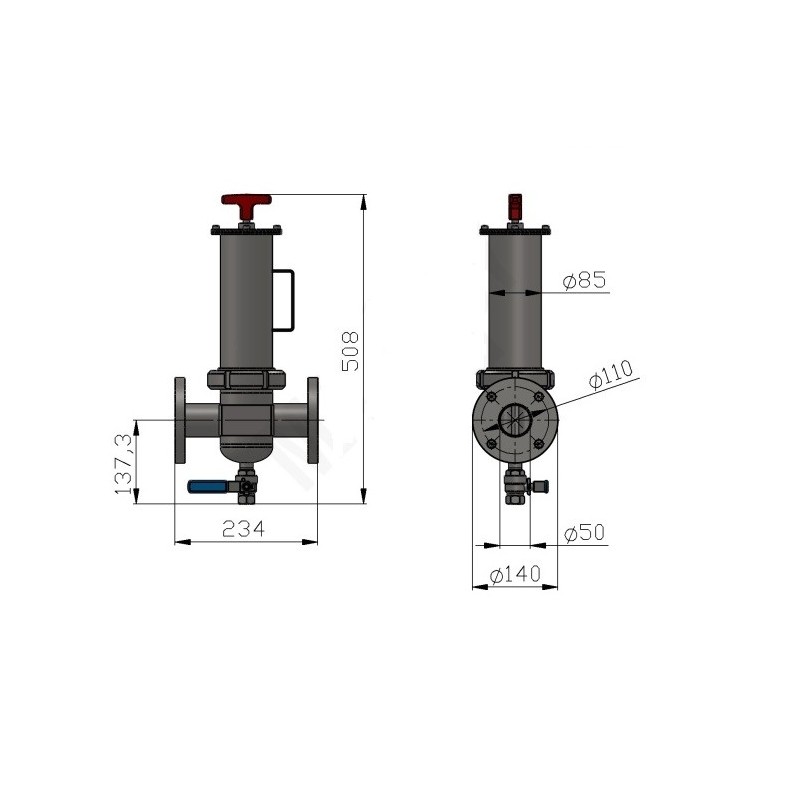

The main elements of this magnetic separator are the separator body, separator component and connecting elements. The pipe-like body is mounted firmly to the material pipeline using connecting elements. The body is a separation space. The body size is given by the size (clearance) of the separated material pipeline, and it is designed in a manner that the separator as such does not reduce the separated material flow rate, and the operational conditions are not changed.

Body material dimension is always such that it respects operational conditions of the separated material pipeline (pressure resistance, welds). The component is removable, and it consists of the covering pipes, sliding magnetic cores and sliding mechanism including a pull bar.

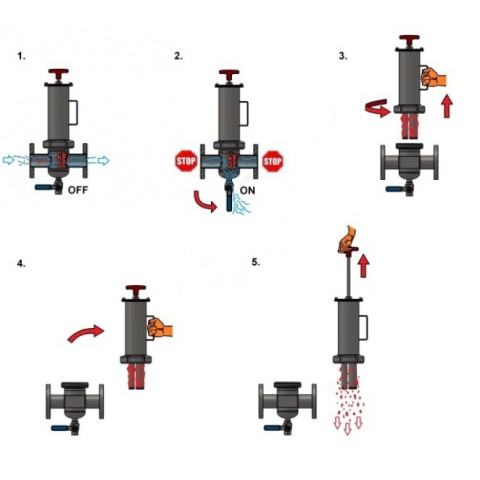

During the own separator cleaning process, the component is removed from the separator body in order to perform the cleaning as such out of the material flow. Using the sliding mechanism, the cores are moved to the component upper part. This way, the pipes become demagnetized and Fe particles caught can be removed from the covering pipes easily.

Magnetic cores in the pipes form a magnetic field in which magnetic particles, impurities are induced and attached to the pipes surface. They remain caught there, mainly on the side opposite to the medium flow direction. MF separator is installed into the separated material pipeline system as needed ŌĆō in the vertical or horizontal position.

- Material: Stainless steel

- Country of origin: Slovakia