Screw Destoner / Vegetable Washer DEH

The destoner lift machine is designed for pre-washing and transporting root vegetables such as potatoes, carrots, beets, and other similar vegetables. After rinsing, the auger destoner separates floating particles like leaves and stems in the receiving hopper, while the product is conveyed up to the discharge height using a screw lift.

- Allows you to separate stones, leaves from root vegetables

- Pre-washing of root vegetable crops

- Two functions in one unit: washing and transporting

- Spacious hopper/tub for loading the product

The screw destoner is designed for pre-washing and removing debris from root crops, such as:

|

|

|

|

|

|

|

Advantages

- Treats the product with care

- Both washing and removing stones in one compact machine

- Ease of operation and maintenance

- Made from high quality stainless steel

- Adjustable auger speed using a frequency converter

The basic version consists of a rectangular hopper for water intake and a vertical pipe with a discharge conveyor screw.

Principle of operation

The product to be destoned is placed in the water hopper and carefully lifted with the water into the pipe by rotating the auger. The rotating motion lifts the product and allows water to drain from the walls of the auger. Heavy parts that cannot be lifted to the surface by water remain at the bottom of the bunker. Clean product (with no stones) comes out of the top of the auger lift.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The rotary drum cooler is designed for efficient pre-cooling, stopping the cooking process, and cooling of boiled, blanched, fried, baked, or thermally processed foods. The rotating perforated drum ensures uniform cooling together with the additional water supply.

- Uniform cooling

- Adjustable drum speed

- Made entirely out of stainless steel

- Suitable for a wide range of food products

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 1,1

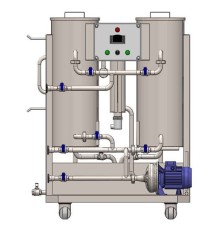

CIP-52: Clean-In-Place - Machine for cleaning and the disinfection vessels and pipelines in breweries and other food processing plants with two 50 liter tanks.

- Material: Stainless steel

- Country of origin: EU

The machine is used for brushing, cleaning as well as prewashing various root vegetables.

- Material: Stainless steel

- Engine power, kW: 2,2

The container washer for canned food is a specialized washing system designed to thoroughly clean containers used for canning food products, ensuring hygiene and sanitation standards are met within your food processing facility.

This equipment model has been discontinued from serial production and is available only as a custom project upon request.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Our tunnel container washers are designed to wash different kinds of plastic containers.

- Material: Stainless steel

- Heating power, kW: 15/ 20

- Principle of operation: Continuous mode

- Voltage: 380-400V

Fruit washer is designed for washing and cleaning products such as fruit or vegetables before processing, especially apples.

If you're looking for any other fruit and vegetable washers, send us a request.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

Keg washing and filling machine used for washing and filling kegs and barrels for beer, cider, wine and other beverages.

- Material: Stainless steel

- Engine power, kW: 0,75

- Operation mode: Manual

- Voltage: 220-230V 380-400V

The drum washer is designed for washing potatoes and other roots as well as for seeds, nuts and grains.

- Material: Stainless steel

- Engine power, kW: 1,1

- Principle of operation: Continuous mode

- Country of origin: Slovakia

CIP-51: Equipment for cleaning and disinfection of vessels and pipelines in breweries and other food industries with one tank of 50 liters

- Material: Stainless steel

- Country of origin: EU

- Productivity: 800 psc/h

- Material: Stainless steel

- Operation mode: Semi-automatic

This machine allows washing and sterile rinsing with dry steam of cans and cups before filling them with product.

- Productivity: 6000 psc/h

- Material: Stainless steel

- Principle of operation: Continuous mode

Vegetable washers are designed to clean and prepare vegetables for consumption or further processing.

We offer different types of vegetable washers.

- Material: Stainless steel

- Engine power, kW: 0,47 / 1,45 / 1,85

- Type of the equipment: Individual machine

- Country of origin: EU

- Volume: 160 l/ 300l/ 600l/

This open tank is intended for washing the juice tanks. Kapacity 250L.┬ĀFor more information, send us a request.┬Ā

- Material: Stainless steel

- Volume: 250l/

CIP-202: Cleaning-In-Place - Machine for cleaning and disinfecting vessels and pipelines in breweries and other food processing plants with two 200 liter tanks.

- Material: Stainless steel

- Country of origin: EU

- Volume: 200l

Bubble washer for gentle washing and cleaning of fruits and berries, for example peaches, cherries, strawberries and other raw fruits prior to their further processing.┬Ā

- Principle of operation: Continuous mode

- Country of origin: EU

- Working Area Width: 600 mm/ 800 mm/ 1000 mm

The brush washer/scraper is an industrial device for washing and scraping root vegetables depending on the degree of contamination.

- Productivity: 300 kg/h

- Material: Stainless steel

- Engine power, kW: 1

- Voltage: 230 V/ 380-400V