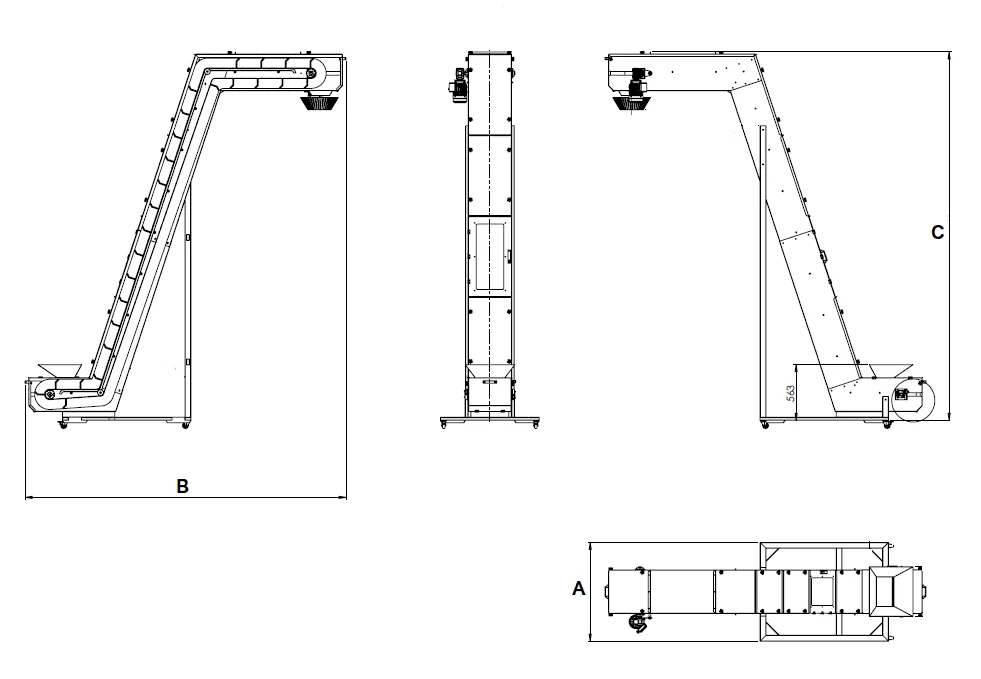

Z-shaped Conveyor MBC 300

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. The price depends on the product as well as the size of the conveyor.

Z-shaped small conveyor are frequently used to discharge small products but also bulk products from production and packaging equipment and for filling into tanks or delivering to other processes.

Depending on the measurements and customerŌĆÖs needs, different base frames, drive system and belt materials are possible to provide an optimal adaptation to the specific projects.

Z- shaped conveyors are used in a diverse applications:

- Ergonomic help for the staff: incline will help eliminate the need for bending or reaching)

- Hoppers or bowl feeders: customized declines could be implemented for feeding the goods into hoppers

- Hight changes

- Packaging

- And many others

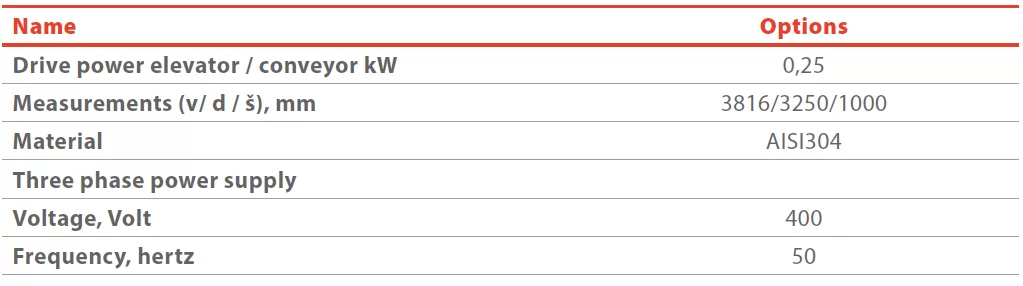

Technical specifications:

- modular PVC food industry conveyor with drivers

- Working width of the belt 300 mm

- height of the partition - 100 mm (curved profile at an angle of 45 ┬░)

- spacing between dividers - 250 mm

- mobile version

- AISI304 stainless steel construction material and hopper

- Covering the conveyor from above or from the below

- Frequency converter - Speed control of the belt

- Start/Stop system from the packing machine

- converter switch communicates with level sensor of the packing system

- Belt speed approx. 15m / min.

Transport inclined Z-shaped bulk conveyor - refers to the equipment of continuous action for lifting and transporting products for further processing, packaging. The equipment is intended for use in the food industry. The easily extended flat belt parts of Z-shaped conveyor allow small construction heights with no distress to the base frame.

- Material: Stainless steel

- Engine power, kW: 0,25

- Working Area Width: 300 mm

- Voltage: 380-400V

You might also like

The inspection conveyor is designed for inspection and manual removal of unsuitable pieces of root vegetables, fruits and berries.┬Ā

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

CAC Air cooling conveyors are designed for intensive cooling and removal of excess water or oil (air knife section) from products after frying, cooking or blanching.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 500 mm

- Voltage: 380-400V

Washing tank with wheels with conveyor belt for fruits and vegetables.

- Material: Stainless steel

- Engine power, kW: 2,4/

- Principle of operation: Continuous mode

- Country of origin: EU

- Working Area Width: 330 mm

- Voltage: 380-400V

Optional module for the 400/1100/12 universal tabletop Modular Fryer - Pressure Conveyor for frying foods that require forced immersion in oil.

- Material: Stainless steel

The screw elevator is intended for transporting grape marc / bagasse. It also suitable for processing olives. This type of an elevator is great for food production facilities focusing on fruit processing as well as wine and olive oil production. The machine is made in two models with 3000 and 4000 mm length.┬Ā

- Productivity: 2-10 ton/h

- Engine power, kW: 1,5 KW

- Principle of operation: Continuous mode

Adjustable conveyors made out of stainless steel construction with a large 100 L loading hopper suitable for the food industry.

- Material: Stainless steel

- Engine power, kW: 0,25

- Working Area Width: 300 mm

Washing tank with wheels with conveyor belt for fruits and vegetables.

- Material: Stainless steel

- Engine power, kW: 2,4/

- Principle of operation: Continuous mode

- Country of origin: EU

- Working Area Width: 330 mm

- Voltage: 380-400V

Variable belt conveyor with wide use not only in the food industry. The length of the conveyor can be selected from 2 to 6 m. The width of the belt is 200 and 400 mm.

- Engine power, kW: 0,75

- Principle of operation: Continuous mode

The paddle module for the 400/1100/12 Universal Tabletop Modular Fryer is a conveyor with specially curved paddles for gentle frying of fragile and light foods.

- Material: Stainless steel

- Type of the equipment: Optional equipment

Vibrating conveyors suitable for arranging the product before further processing.

- Working Area Width: 720 mm

- Voltage: 380-400V

It is intended for pre-cooling after cooking or frying vegetables and fruit, meat, fish and seafood and other products.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 600 mm

CAC Air cooling conveyors are designed for intensive cooling and removal of excess water or oil (air knife section) from products after frying, cooking or blanching.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 500 mm

- Voltage: 380-400V

The incline screw conveyor is used for transporting a wide range of bulk, powdery, fine-grained, and dusty products in food, chemical, construction, or agro-industries.

- Material: Stainless steel

- Engine power, kW: 0,75 1,1/ 1,5 / 2,2

A universal conveyor with a PVC belt with horizontal sections, a volumetric storage, adjustable in height and angle of inclination, which can easily be adapted to existing installations for lifting the product to a certain height. The conveyor has its own independent drive, the speed of which can be adjusted using an inverter (optional).

- Lightweight: the supporting structure of the conveyor is made out of aluminum profiles

- Hopper made out of food grade stainless steel

- Bearing frame on wheeled supports with position locks

- High sidewalls made out of stainless steel

- White PVC tape for transporting products with temperatures of up to 80 degrees

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 500 mm

- Volume: 50l/

The sorting and transporting table or conveyor is suitable for manually sorting and delivering products to the next processing stage.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Width: 530 mm

The inspection conveyor is designed for inspection and manual removal of unsuitable pieces of root vegetables, fruits and berries.┬Ā

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

An air cooling conveyor is used to rapidly cool products in food processing industries by circulating cool air over them as they move along a conveyor belt. This efficient cooling process helps preserve product quality and reduce the time between processing stages, facilitating smoother production workflows.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. Price depends on the product and size of the conveyor.

- Material: Stainless steel

- Engine power, kW: 0,25

- Weight: 100

The bucket elevator is designed for transporting loose bulk materials, such as grain and seeds in a vertical position. It's an ideal solution for transporting various products for the baking industry as well as animal feed and other granular productions.

- Principle of operation: Continuous mode