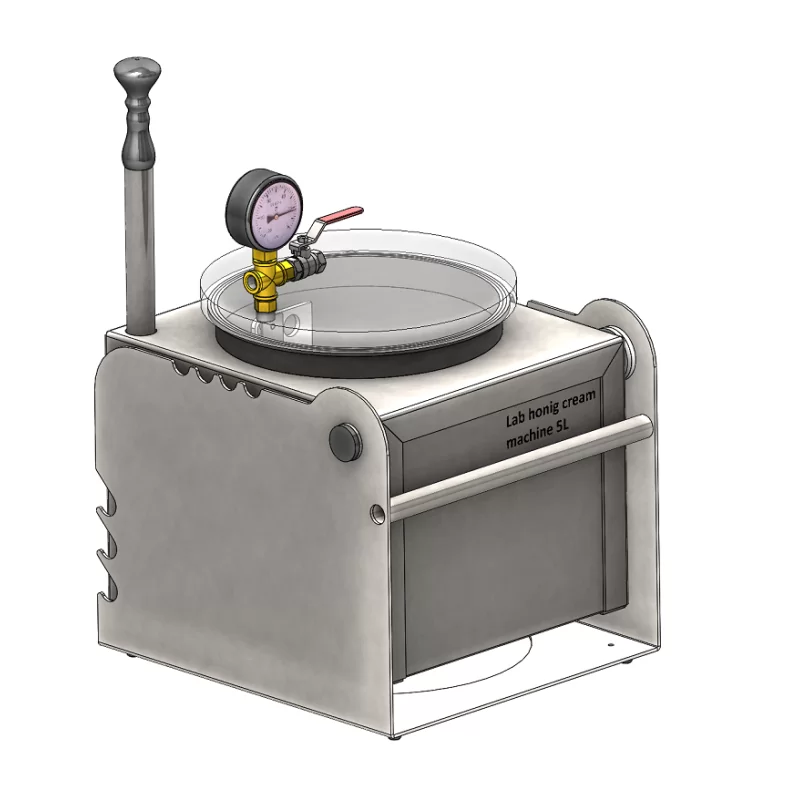

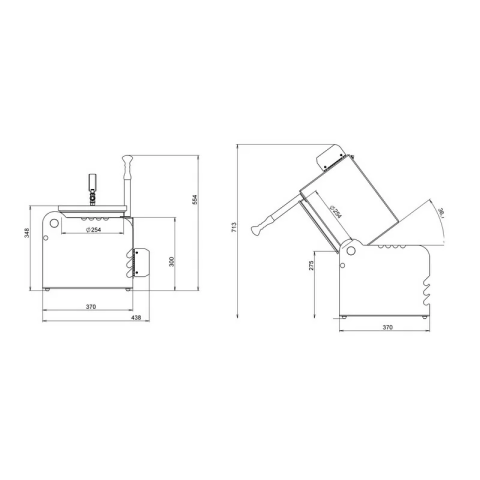

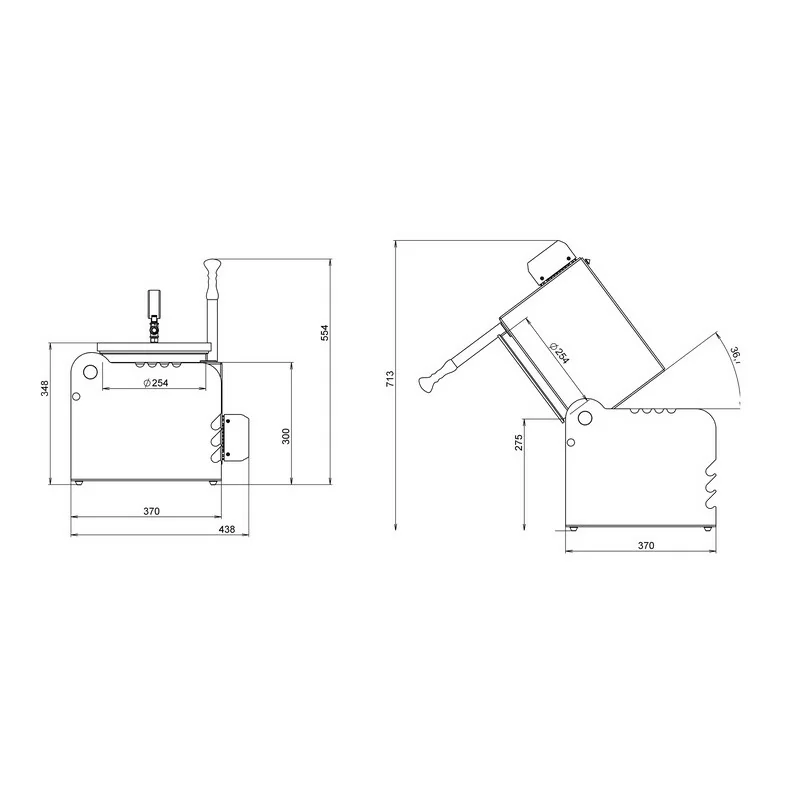

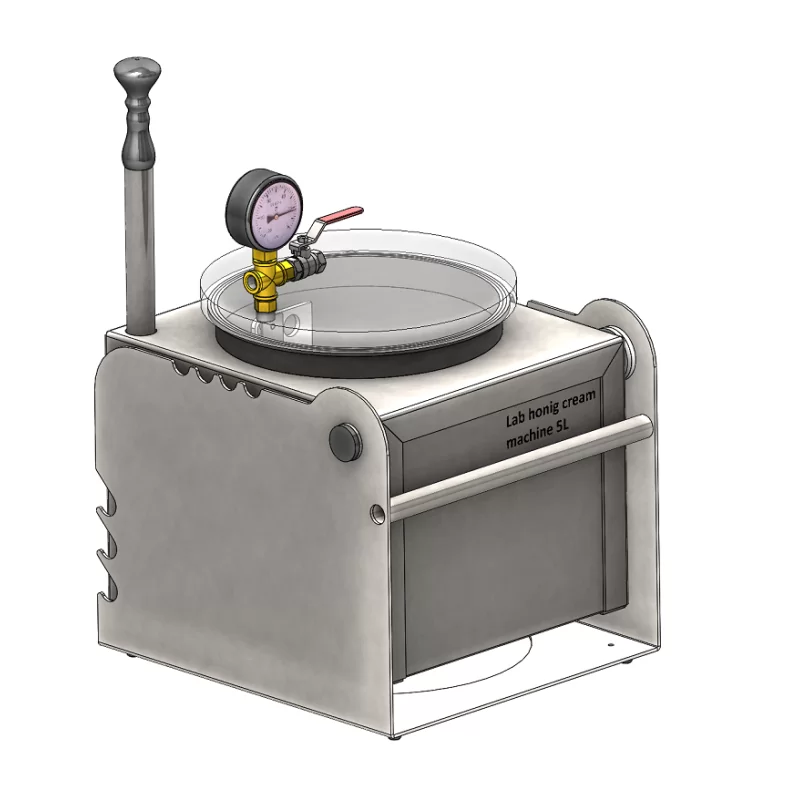

Small pilot vacuum processing plant MINI5

Multifunctional vacuum unit MINI5 - is ideal for cooking, drying, concentrating, mixing and much more. Suitable for laboratories and small-scale production.

- Processing heat-sensitive products at lower temperatures

- Ideal for making creamed honey

- Possibility of vacuum drying honey

Suitable for both laboratory as well as small-scale production applications.

This installation can produce a large number of different food products, for example:

|

|

|

|

|

|

|

|

Advantages:

- Ideal for making creamy honey.

- Suitable for the vacuum concentration of various products.

- Possibility of the vacuum drying of honey.

- Designed for the production of sugar paste and for sugaring under vacuum.

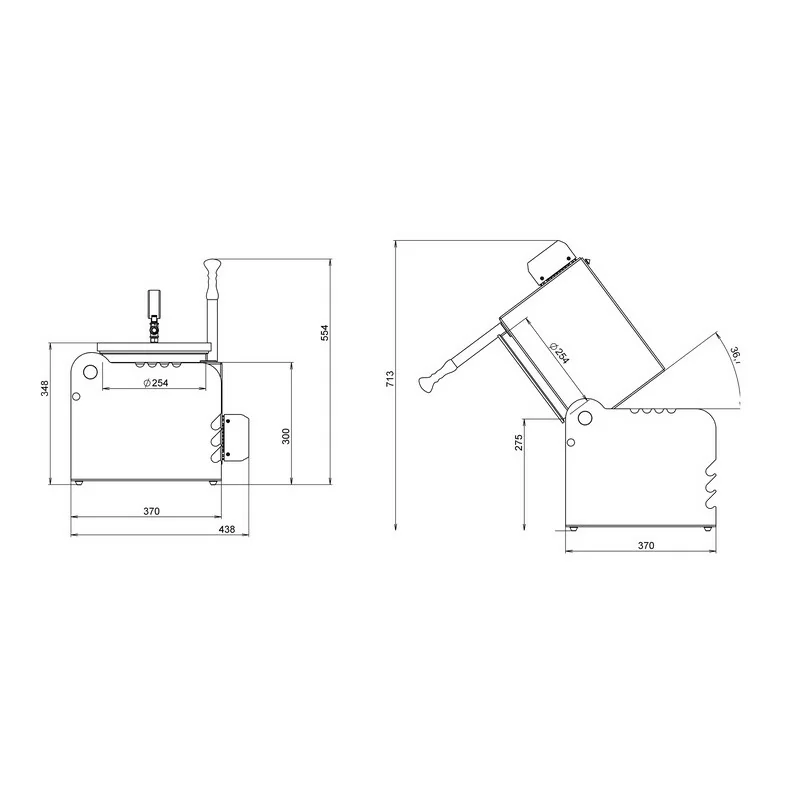

Basic version

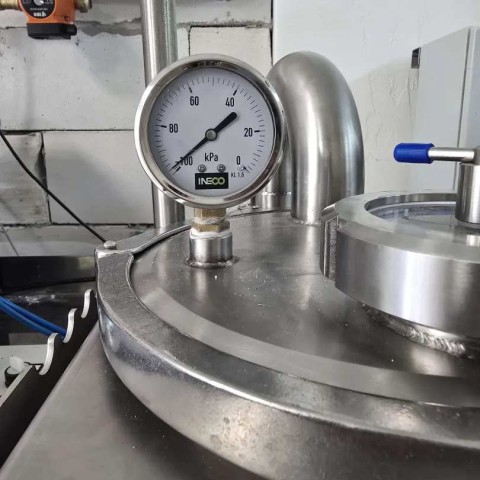

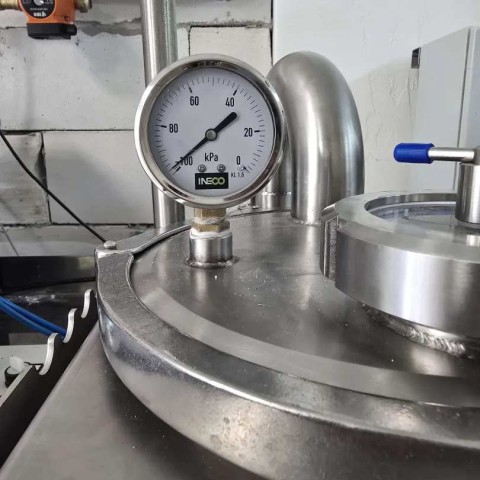

The laboratory vacuum unit is equipped with a mixing device with Teflon scrapers, a jacket for the coolant on the bottom and walls of the unit, a vacuum system and a transparent upper housing for visual monitoring of the cooking process.

Options:

- Secondary steam removal and condensation system

- Flow heater

- Chiller (cooling machine)

- Table on wheels

- Material: Stainless steel

- Engine power, kW: 0,12

- Country of origin: Slovakia

- Volume: 5l

You might also like

The price is set for the basic version of the installation without additional equipment.

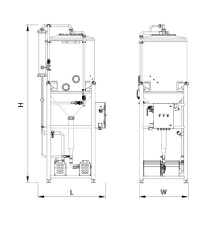

The vacuum homogenizer is designed for a wide range of processes such as for the production of mayonnaise, ketchup, various sauces, confectionery pastes and fillings, liquid or paste like products with a homogeneous structure. It is also suitable for the production of various creams, gels, shampoos and other products in the cosmetic industry.

- Built-in Ultra Shear bottom homogenizer

- Mixing device with movable scrapers

- Tilting version for easy unloading

- Wide range of applications

- Entirely made of food grade stainless steel AISI304/ AISI316 - option

- Compact design

- Lots of additional options to choose from

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 20l/ 50l

- Total power, kW: 2,3/ 2,4

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

A circulation-type vacuum evaporator refers to a combined version of an evaporator that also takes advantage of other types to improve evaporation efficiency particularly by reducing concentration time and when processing heat-sensitive products such as milk.

- The external circulation circuit with heating intensifies the cyclic evaporation process.

- The forced circulation system ensures a decrease in the risk of localized product overheating.

- The condenser enables a deep vacuum and maintains a low evaporation temperature.

- Utilizing a mixing device with a spray system facilitates product evaporation in a thin layer, mimicking a film-type evaporator.

- Heating: Steam

- Material: Stainless steel

- Operation mode: Semi-automatic

- Country of origin: Slovakia

- Total power, kW: 2,4

- Voltage: 380-400V

Compact vacuum evaporation machine with an external circulation heat exchanger for the production of test batches of products, development of new recipes and technological maps.

- Compact installation

- Capable of replicating all processing techniques used in industrial vacuum evaporation units with circulation

- Preserves the natural taste, aroma and color of the product

- Can be used to produce small batches of products

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Volume: 20l

Vacuum evaporator with remote circulation using a heat exchanger is one of the most efficient evaporation methods. This evaporation system is suitable for boiling and concentrating heat-sensitive products such as milk, cream, etc.

- No mixing device required, the product has forced circulation!

- Modular system: possibility to choose the vacuum generator, power and heat exchanger type

- Inclined design and bottom valve for 100% product discharge without losses and blind spots

- Insulated upper hatch of the unit for heat retention and safety

- Tangential product inlet into the vacuum vessel for guaranteed evaporation in a thin layer

- Material: Stainless steel

- Volume: 50l/ 100l/ 300l

Price depends on the capacity and product.┬Ā

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

The Atmospheric Evaporating Pan efficiently concentrates liquids by evaporating them on a large surface area, while also being suitable for various cooking methods including braising, cooking, and roasting.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

An evaporating unit is utilized to remove moisture from sweet substances through heating, transforming them into concentrated syrups or solutions.

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Voltage: 380-400V

- Geometric volume: 200 l

We offer different types of vacuum evaporation machines, this type is an affordable option for efficient evaporation in a stainless steel unit.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l

Small 3L vacuum unit with a stirring device for the production of non-alcoholic wine.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Volume: 5l

An evaporator concentrator-crystallizer is a multifunctional unit that concentrates liquids by evaporating water and inducing crystallization for the production of concentrated solutions or crystalline products.

- Material: Stainless steel

- Working volume: up to 6000 L

- Geometric volume: 6500 l

A circulation-type vacuum evaporator refers to a combined version of an evaporator that also takes advantage of other types to improve evaporation efficiency particularly by reducing concentration time and when processing heat-sensitive products such as milk.

- The external circulation circuit with heating intensifies the cyclic evaporation process.

- The forced circulation system ensures a decrease in the risk of localized product overheating.

- The condenser enables a deep vacuum and maintains a low evaporation temperature.

- Utilizing a mixing device with a spray system facilitates product evaporation in a thin layer, mimicking a film-type evaporator.

- Heating: Steam

- Material: Stainless steel

- Operation mode: Semi-automatic

- Country of origin: Slovakia

- Total power, kW: 2,4

- Voltage: 380-400V

A vacuum evaporator is a device used to evaporate liquids at lower temperatures by creating a vacuum environment, which reduces the boiling point of the liquid and enables efficient evaporation without thermal degradation of sensitive materials. Working volume up to, l: 1900 l.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: up to 1900 l

Compact vacuum evaporation machine with an external circulation heat exchanger for the production of test batches of products, development of new recipes and technological maps.

- Compact installation

- Capable of replicating all processing techniques used in industrial vacuum evaporation units with circulation

- Preserves the natural taste, aroma and color of the product

- Can be used to produce small batches of products

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Volume: 20l

The compact line of double-type vacuum cooking kettles comprises a complex of batch food cooking units designed for periodic thermal processing, vacuum mixing, and deaeration of various products under sub-atmospheric pressure.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 2x300l/ 2x600l

Plant for evaporating, concentrating and crystallizing solutions. Vacuum evaporator ensures a complete separation of the solution into a solid fraction and pure water.

The price is set for the basic version of the vacuum evaporation unit with basic controls (mixer motor switch) and without additional options. The control unit is customized based on individual customer requirements. The pump is also selected separately depending on the product.

A compact vacuum evaporation unit that allows you to concentrate solutions, mixtures, and various products by evaporating the solvent. A modular version based on the basic version of the 110/100 vacuum reactor.

- Gravity mixing - 25% more efficient

- Reinforced agitator design with no blind spots

- Bottom ball valve with no dead zones

- Condensation and secondary vapor removal system

- Easy to disassemble mixing device

- Large heat exchange area

- Ability to measure and monitor condensate volume (optional)

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

- Working volume: 50-80l

- Condensing capacity, l/h: 45-55

- Steam consumption, kg/h: up to 150

The vacuum cooking and concentration unit is designed for concentrating products at low temperatures (about 60 degrees) in a reactor with a discharged environment to preserve the color, nutritional value and useful natural substances in present in food products. Evaporation and concentration units are often used when cooking jams, sauces, as well as fruit or vegetable concentrates. The vacuum concentrator allows you to boil and concentrate heat-sensitive products without damaging or destroying their structure or proteins, such as milk.

- Inclined design - allows for gravity mixing, which is 40% more efficient than usual

- Quick and 100% emptying of the tank thanks to the inclined design with the mixer on

- Heating/cooling jacket (duplicator) for the working tank and bottom

- High hygiene standard - the output valve is located at the lowest hydraulic point of the reactor

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l/ 500l/ 875l

This equipment model is a universal system, which can be used to produce extracts from products like carobs, as well as to boil them under vacuum conditions to obtain a thick syrup through a sequential circulation process.

- One system for all sequential technological processes of pekmez production: from soaking and obtaining an extract, cooling the finished mixture to its boiling phase in a vacuum.

- Boiling under vacuum allows you to preserve all the useful substances contained in the extract: vitamins of group A, B, E, microelements such as calcium, potassium, magnesium, iron and zinc.

- Highly efficient boiling process due to a special direct in the flow heating system installed in the circulation type vacuum evaporation unit

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 36

- Volume: 100l

- Condensing capacity, l/h: 45-55

Installations for the production of non-alcoholic wine are manufactured in various models and configurations starting from volumes of 100 liters. The systems operate on the principle of vacuum distillation, which allows for alcohol removal at low temperatures, resulting in a healthy product with minimal alcohol content.

- A wide range of models ŌĆö suitable both for small-scale production and large-scale industrial operations

- Capability to produce a "healthy product" while preserving all organoleptic properties of the beverage

- Depending on production capacity, the systems can be designed for batch or continuous operation

- Deep vacuum conditions allow for low evaporation temperatures, enabling especially gentle evaporation without thermal degradation of the flavor profiles of different types of wine

- Material: Stainless steel

- Country of origin: Slovakia

Vacuum evaporator with remote circulation using a heat exchanger is one of the most efficient evaporation methods. This evaporation system is suitable for boiling and concentrating heat-sensitive products such as milk, cream, etc.

- No mixing device required, the product has forced circulation!

- Modular system: possibility to choose the vacuum generator, power and heat exchanger type

- Inclined design and bottom valve for 100% product discharge without losses and blind spots

- Insulated upper hatch of the unit for heat retention and safety

- Tangential product inlet into the vacuum vessel for guaranteed evaporation in a thin layer

- Material: Stainless steel

- Volume: 50l/ 100l/ 300l