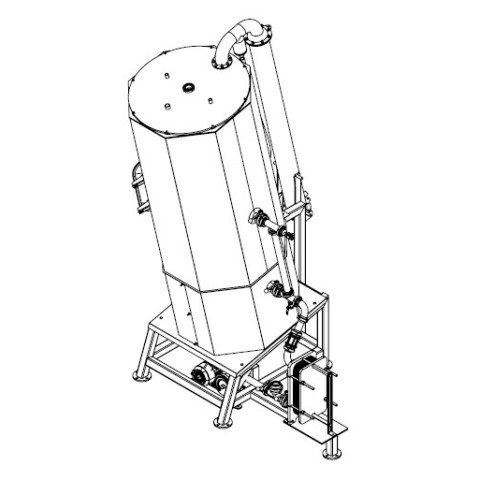

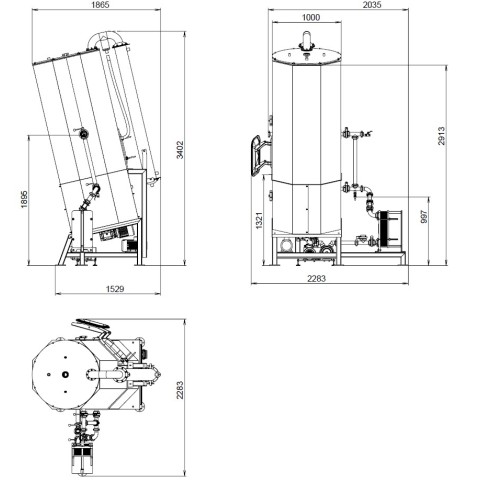

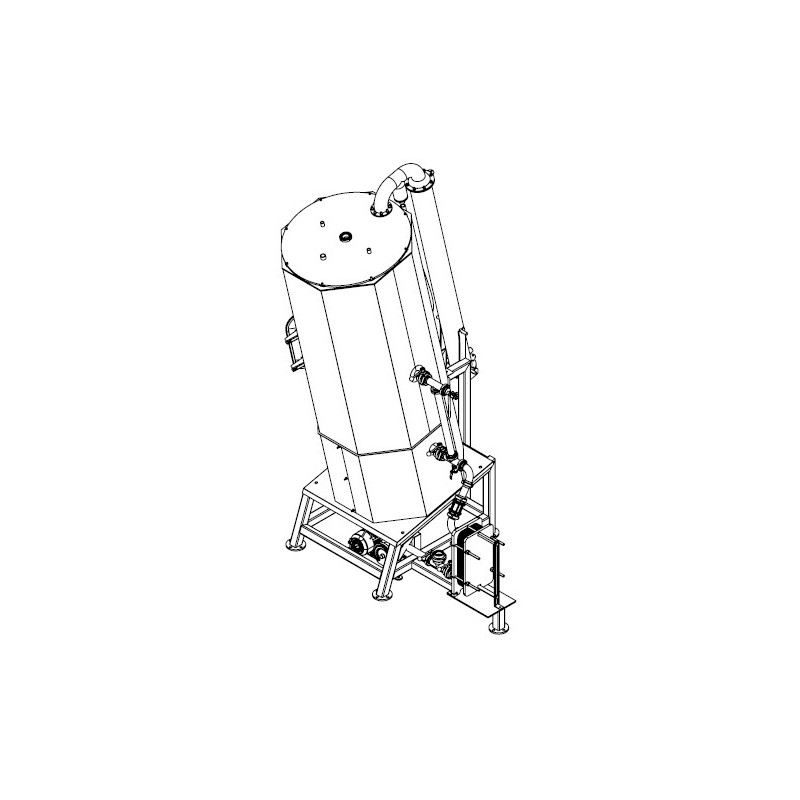

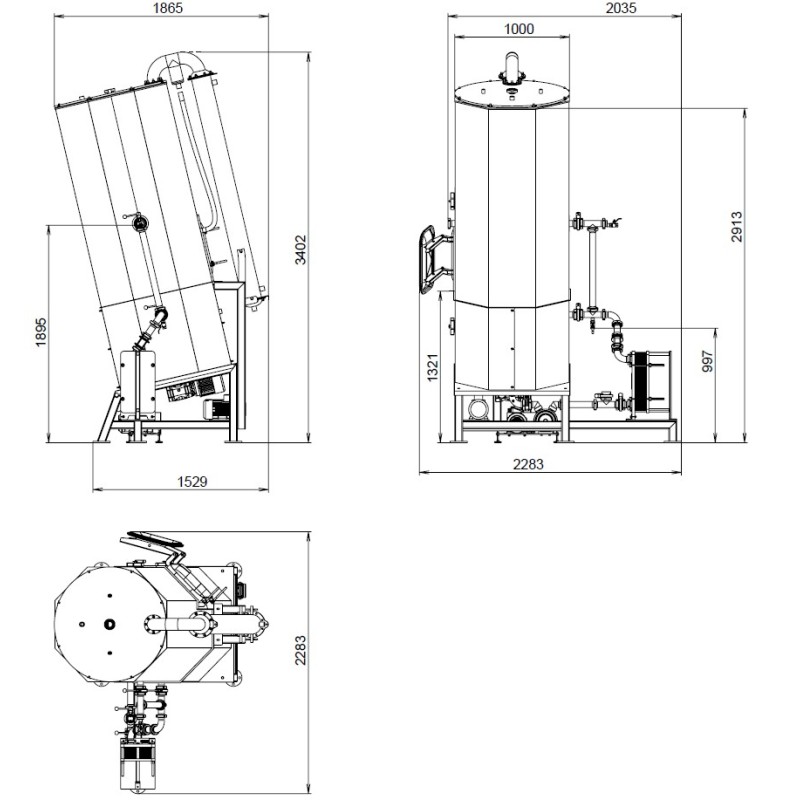

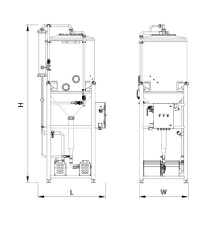

Vacuum evaporation plant circulation-type 1750/1500/15

A circulation-type vacuum evaporator refers to a combined version of an evaporator that also takes advantage of other types to improve evaporation efficiency particularly by reducing concentration time and when processing heat-sensitive products such as milk.

- The external circulation circuit with heating intensifies the cyclic evaporation process.

- The forced circulation system ensures a decrease in the risk of localized product overheating.

- The condenser enables a deep vacuum and maintains a low evaporation temperature.

- Utilizing a mixing device with a spray system facilitates product evaporation in a thin layer, mimicking a film-type evaporator.

Evaporation systems are extensively utilized not only in the food industry but also in the chemical, pharmaceutical, and cosmetics sectors. Concentration serves not only as the primary process but also as an intermediate step before drying various liquid, flowing products. The evaporation process involves thickening liquid masses by extracting a solution from them in the form of steam, which is then removed from the working chamber of the equipment. While water evaporation is typical, the chemical industry may involve the evaporation of other types of solutions.

Vacuum evaporation plants in the food and other industries are necessary for processing products such as:

|

|

|

|

|

|

|

|

|

|

Vacuum evaporation units can also be used as basic cookers in the confectionery or dairy industry for cooking products under vacuum conditions. A vacuum allows you to reduce the boiling point of various mixtures, prevent changes in the molecular structure, the possible caramelization of sugars in raw materials being processed as well as to preserve the natural color and taste of the product. Many vitamins and useful minerals get destroyed by high temperatures, so in the production of various nutritional supplements and natural medicine tinctures, it is necessary to concentrate the ingredients exclusively under a vacuum.

Vacuum evaporators can operate on various principles, typically leveraging the advantages of their respective types. While there are numerous classic versions of vacuum evaporator units, advancements in improving and modernizing their operation continue to progress.

Our evaporation system is a new hybrid version of a single-effect vacuum evaporator, incorporating the most effective and beneficial features from various types of concentrators.

Advantages:

- The slanted design of the evaporator's working reactor guarantees maximum emptying of the tank, with the outlet valve installed at the lowest hydraulic point of the vessel. There is no need to install expensive bottom valves, to ensure 100% unloading of various masses of products and reduce product losses to a minimum.

- Gravity mixing is 50% more effective than classical mixing methods. This is especially important, for example, when mixing various ingredients into the bulk of the product or when combining sugar syrup with concentrated milk. The product flows into the lower part of the reactor, where it is picked up by the blade of the mixing device and moved upward to the center of the installation. When processing thick and viscous mixtures, it is recommended to install scrapers (optional), which help not only to mix the product but also to clean its residues from the walls of the installation. Thanks to this, the components are evenly distributed in the total mass of the product.

- A single-unit evaporation plant with a remote heat exchanger has a great advantage - high evaporation intensity without local overheating. The product pump ensures constant circulation of the product at a consistent speed through the heat exchanger, preventing the product from burning or overheating when passing through the heat exchanger. The choice of the type of a heat exchanger (plate or shell-and-tube) depends on the type of product being processed. All types of heat exchangers are designed to use steam as a coolant. This is the fastest and most efficient method of heating temperature-sensitive products.

- The hybrid nature of the evaporation unit ensures evaporation occurs in a thin layer, similar to film-type evaporation units. Upon entering the evaporation chamber, the liquid is dispersed into fine sprays inside the chamber due to the rotation of the mixing device (a special spray system can be installed as an option). The product, upon contact with the rarefied environment, is almost immediately cooled due to the intense release of steam (instant evaporation). Subsequently, a thin film forms along the heated walls of the container, facilitating further heating and evaporation.

- A special system (trap) with a bypass, installed in front of the condenser, allows you to reduce product losses from the container, especially when processing foaming products, such as milk. When choosing a suitable installation, it is recommended to select a chamber volume 50% larger than the calculated working volume.

- The two-level temperature control system practically prevents the possibility of overheating of the product. The coolant supply is regulated based on data from professional stainless steel temperature sensors in contact with the product in the working chamber, in the circulation flow. When the value of one of them increases, the system automatically turns off the coolant supply.

- The vacuum generation and maintenance system relies on a liquid ring vacuum pump and a large shell-and-tube condenser. Vacuum depth adjustment is automated through a contact vacuum gauge. To ensure proper operation of the liquid ring pump and condenser, it is essential to have a source of ice water with a temperature between 5 to 7 degrees Celsius.

- Visual control - there is an inspection window on the units body (depending on the configuration, it can be equipped with a backlight or a windshield wiper). On the condenser outlet pipe, there is a flow-through glass section that allows you to control the evaporation process (condensation of vapors and their removal from the installation).

Basic version

Our evaporation system comprises a 4-layer inclined vacuum reactor with a jacketed bottom and walls for the coolant (up to 0.5 bar), thermal insulation, and an external casing crafted from food-grade polished stainless steel. It is designed with thick walls at the bottom and upper body to ensure the vessel's stability under vacuum conditions. All components that come into contact with the product are made out of food-grade stainless steel or materials certified for use in the food industry. The mixing device is outfitted with a powerful industrial gear motor from a European manufacturer, alongside an external circulation circuit featuring a product pump and a heat exchanger. The choice of a suitable heat exchanger and the product pump type are tailored to the characteristics of the processed product. Additionally, the installation is equipped with a vapor removal and condensation system complete with a trap.

Semi-automatic control: allows for the regulation of heating temperature, rotation speed of the mixing device, vacuum creation, and product pump control. The system is equipped with both shut-off and regulating food-grade mechanical valves.

To clean the installation, CIP cleaning heads can be installed. The service hatch on the reactor can also be used for servicing and cleaning the mixing device. The hatch is equipped with an opening sensor, which ensures safe operation for the operator.

Technical conditions

- The working vacuum depth is -0.8 bar (0.2 bar residual), the steaming temperature at this vacuum value is 57-59 degrees C

- The minimum loading volume varies depending on the model and volume, it is recommended that the product covers the bottom of the mixer.

- Maximum loading volume┬Āranges from 50% to 75% of the total volume (depending on the product's foaming properties)

Options

- Scrapers for the mixing device made of Teflon, high-temperature material (PEEK) or stainless steel

- A set for -0.9 bar (40 degrees water evaporation temperature)

- Product spraying system inside the reactor

- CIP heads for cleaning

- Heating: Steam

- Material: Stainless steel

- Operation mode: Semi-automatic

- Country of origin: Slovakia

- Total power, kW: 2,4

- Voltage: 380-400V