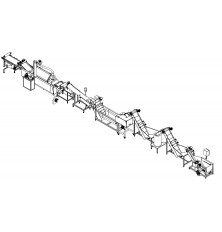

Condensed Milk Production Line

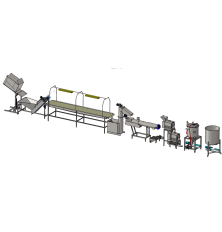

The concentration and thickening line line has been especially designed for industrial dairy production facilities with a small surplus of milk or smaller milk processing businesses that want to expand their product range. It has an estimated productivity of up to 50-120 kg/hour during continuous operation.

- Professional industrial technology with compact dimensions

- A large number of additional equipment and options to choose from

The production of sweetened condensed milk can be carried out according to various technologies and recipes; however, most manufacturers rely on GOST standards, which set strict production requirements and clearly defined procedures. Therefore, our company has specially designed a mini production line that, even with low capacity, fully complies with and replicates the GOST technology for producing sweetened condensed milk from standardized whole milk.

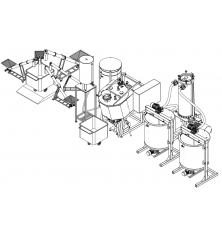

The milk concentration and condensation line, which can be equipped with various options, allows a wide range of processes, including:

|

|

|

|

|

Stewing and caramelization |

Advantages

- Professional industrial technology with compact dimensions

- Wide range of additional equipment and optional features available

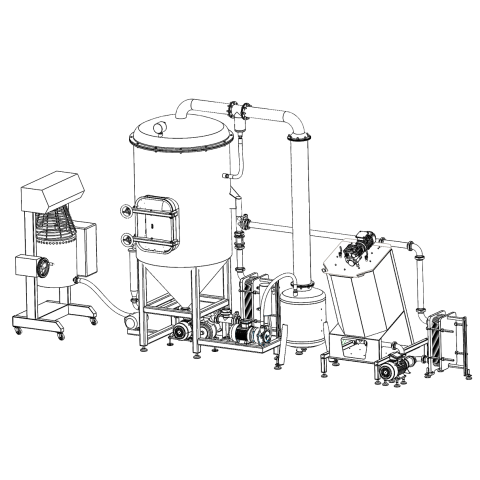

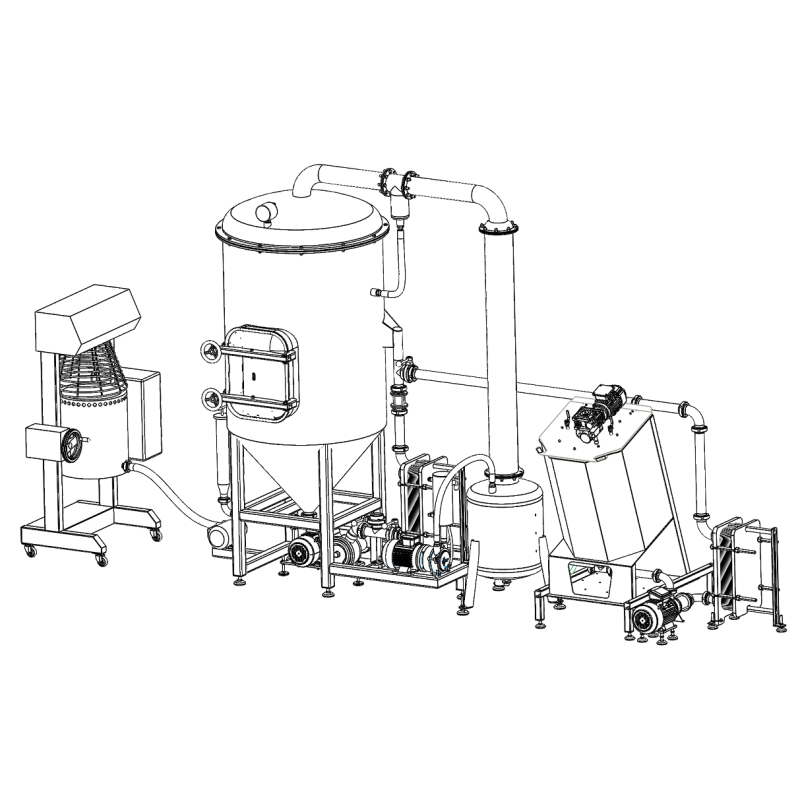

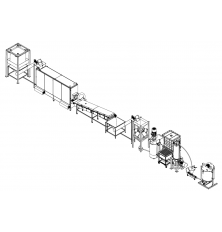

Basic version

The vacuum evaporating unit is the main device for evaporating water from milk at low temperature and reduced pressure. The unit consists of a triple-jacketed conical vacuum reactor with thermal insulation and a polished stainless steel casing. It is equipped with a circulation loop and pump for dense and viscous products and an external plate heat exchanger heated by steam (approx. 3 bar). Hot pasteurized milk (95ā98 Ā°C) enters tangentially into the reactor, spreading into a thin layer. Due to the vacuum, water evaporates quickly at about 60 Ā°C. The secondary steam is discharged through a trap into a condenser connected to a chilled-water source. The process is cyclic ā the milk circulates through the heat exchanger and back to the reactor until the desired density is reached. The density of the final product is typically 1061ā1063 kg/mĀ³. The installation includes a vacuum generation system, product pump control, and a temperature regulator for heating adjustment.

The sugar syrup cooking station is used to prepare syrup for mixing with milk. It consists of a 60-liter kettle operating on thermal oil, used for dissolving sugar during syrup production. The temperature of the thermal oil in the jacket can reach up to 150 Ā°C. The kettle is equipped with lockable wheels, thermal insulation, and an upper safety spiral above the mixing device. Sugar syrup is prepared by mixing crystalline sugar with hot water at 60ā70 Ā°C. After cooking, the mixture must be cooled to 90ā95 Ā°C. It is recommended to prepare syrups with a sugar concentration of 65ā70 %. The syrup is cooked under atmospheric conditions simultaneously with milk concentration and added at the end of the milk boiling process to achieve the desired consistency.

In some recipes, sugar is added directly into the vacuum evaporating unit together with milk. This technology simplifies the production process, shortens the boiling time, and improves the energy efficiency of the process. Adding sugar directly into milk is often used in the production of skimmed sweetened condensed milk. However, this method may have disadvantages depending on sugar quality. When adding dry sugar into pasteurized milk, various microorganisms may enter the mixture. Therefore, in the production of condensed preserved foods, a pre-prepared sugar syrup is usually used. It is also important not to store the prepared syrup for longer than 20 minutes before mixing it with condensed milk in the vacuum evaporating unit. After cooling, the syrup may undergo structural changes, thicken, or crystallize. As a result of sucrose hydrolysis, chemical changes may occur, leading to sucrose decomposition into glucose and fructose. The station can be equipped with an independent control panel or, depending on the model, integrated temperature and mixer speed control on the vacuum evaporatorās main control panel.

The milk pasteurizer ā a batch pasteurization unit used before concentration ā consists of a tank equipped with a jacket for thermal fluid, which allows steam or hot water supply from an external source. This batch pasteurizer serves as an optional device for customers who do not have a pasteurization unit in their production line. Before being fed into the evaporating unit, the milk must reach at least 95 Ā°C. The circulation heating loop of the evaporating unit can also be used for milk heating, depending on the configuration.

The vacuum crystallizer provides controlled sugar crystallization and ensures the desired texture of the final product. It serves for controlled crystallization of the condensed milk-sugar mixture, a key phase affecting product quality. The unit features an external circulation loop with a heat exchanger and a screw pump for cooling the dense mixture without air exposure.

After rapid cooling from 30ā35 Ā°C to about 20 Ā°C, a seed ā usually lactose (0.2 % of weight or milk from previous batches) ā is added. This process triggers lactose crystallization and ensures a fine, dense, and homogeneous structure of the product.

A source of chilled water is required to cool both the crystallizer jacket and the remote heat exchanger. The basic version of the vacuum crystallizer-cooler includes a vacuum reactor with a cooling jacket, a vacuum generation system, and speed regulation for the mixer equipped with fluoroplastic scrapers.

The cooled condensed milk is then transferred into a storage tank, where it is kept for a period to consolidate the crystallization results.

The equipment also enables secondary thermal processing during crystallization.

The cooker-crystallizer is designed for slow cooking of condensed milk under vacuum or slight overpressure (up to 0.5 bar). Heating is performed through the vessel jacket using steam or hot water from an external source. The unit is suitable for final thermal treatment and crystallization of the product.

Product pumps ā ensure the circulation of viscous masses and syrups between devices.

Refractometer (optional) ā measures dry matter content in real time during the concentration process.

Steam generator (optional) ā serves as a steam source for the heat exchanger.

Chilled-water unit (optional) ā provides cooling for the condenser and during product crystallization.

Operating principle

The vacuum evaporating unit operates with a triple-jacketed reactor and forced circulation through an external heat exchanger. Pasteurized milk (95ā98 Ā°C) is tangentially fed into the reactor, where water evaporates rapidly under vacuum at about 60 Ā°C. The secondary steam is directed to a condenser that requires chilled water. The process runs cyclically ā the milk circulates until the desired density is achieved. Mixing of syrup and milk occurs either within the evaporator or after concentration, depending on the recipe.

Crystallization takes place in the vacuum crystallizer with intensive cooling and seed addition (lactose or condensed milk), resulting in a smooth texture. The cooled product is stored in a tank for stabilization.

Optional equipment

- Refractometer ā inline dry-matter sensor with display, no sampling required

- Stainless-steel inline filter for syrup cooking station

- Syrup sprayer

- Steam generator

- Chilled-water unit

- Filter and pump for syrup

- Control panel for the station

In production lines for sweetened condensed milk with a capacity of 285 kg/h, we also offer inclined models of vacuum evaporating units that can be equipped with a jacket and electrically driven agitator.

Technical parameters

- Material: stainless steel

- Material: Stainless steel

- Principle of operation: Continuous mode