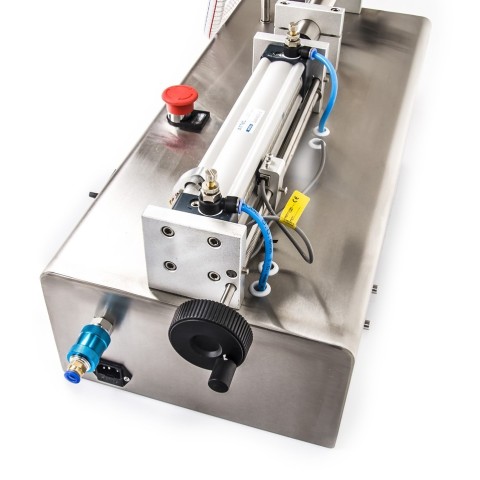

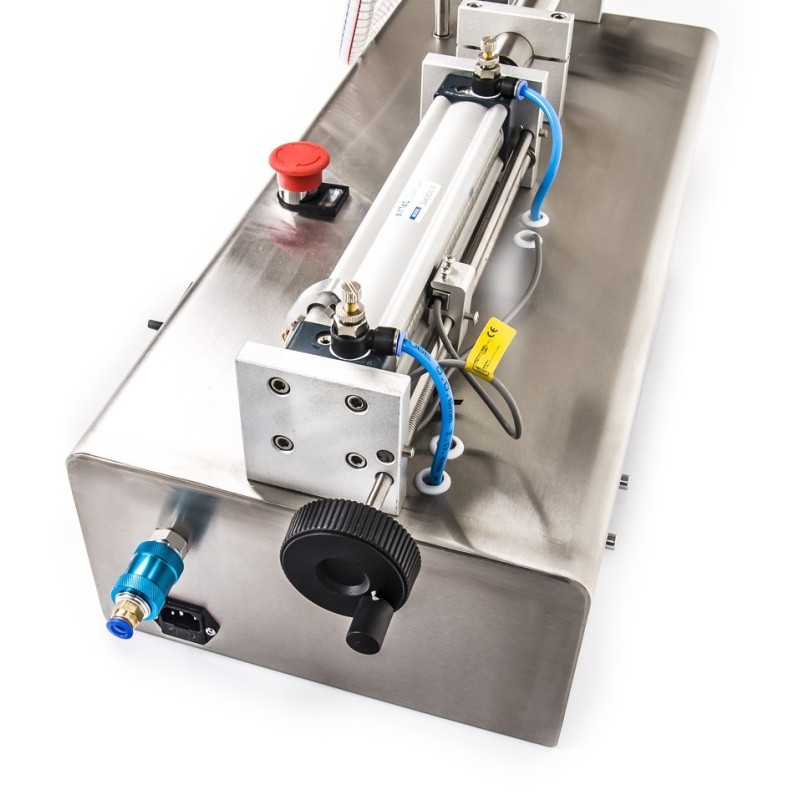

Piston filler for liquids 10-100 ml

The piston-operated pneumatic liquid dispenser is a semi-automatic filler used for dispensing various low viscosity liquids ranging from 10 to 100 ml in volume.

- Compact tabletop installation

- Simple control with two operating modes: manual and semi-automatic

- Suitable for liquid products with low viscosity (from water to oil)

- Optional compressed air compressor available

A volumetric dispenser for packaging liquid products with low viscosity and a small volume, it is often used in small production facilities in both the food and cosmetics industries.

Advantages

- The dispenser itself sucks in the dosed liquid through a piston, meaning there is no need to supply liquid under pressure, which is the main advantage of this dispenser.

- The dosing head is equipped with a blunt needle with an internal diameter of 4.6 mm and a length of 48 mm. The head can rotate freely on the stand. The maximum achievable distance between the center of the head and the dispenser body is 20 cm with the included stand.

- The container with the dispensed liquid can be placed on the floor under the dispenser or at the same height. It can also be placed above the dispenser. The maximum recommended hose length is 2-3 meters - depending on the slope.

- The delivery set includes a set of O-rings and hex keys.

Principle of operation

A piston dispenser operates on the principle of two one-way valves and a piston positioned between them. The piston pushes the liquid forward in one direction and draws the dosed liquid through the pipe upon its return. During extrusion, the outlet valve in the filling head opens pneumatically. This operation is controlled by an electromagnetic pneumatic switch within the device, directing compressed air to the main piston and valve. In one direction, it pushes the piston while simultaneously opening the valve; in the other direction, it pushes the piston to close the valve (T-hub).

The total volume of dispensed liquid is regulated by two electromagnetic sensors that track the piston's position. One sensor remains fixed at the piston's starting point, while the other can be adjusted along the piston's length to manage the piston's travel range and, consequently, the volume of liquid intake and dispensation. The dispensing volume can be adjusted within the range of 10-100 ml. While the dispenser can handle smaller doses such as 5 ml, the manufacturer recommends a minimum dose of 10 ml.

The dispenser can be used both for manual filling - using a foot pedal to start dosing, and in automatic mode, when the dispenser dispenses continuously at a speed depending on the time it takes to move the main piston. This method is suitable for example for a conveyor belt or an experienced operator who can fill at a high speed.

Basic version

The dispenser is made out of stainless steel and aluminum, the parts in contact with the liquid are made out of 304L and 316L stainless steel, which is widely used in the production of kitchen utensils, body piercing, watches, jewelry and is biocompatible. Therefore, there is no risk of contamination of the dosing material. The dispenser also includes a throttle valve as well as a condensate and dust separator (inside the chassis, easily accessible). The dosing liquid is supplied using a pressure hose with a diameter of 32/37 mm. The scope of delivery includes a transparent pressure hose approximately 150 cm long.

Technical requirements

- To operate the dispenser, a 230 V 1A power supply is required, the total consumption is only 10 W (control electronics).

- A source of compressed air with a pressure in the range of 0.4 - 0.6 MPa. The air is connected to the dispenser via a John Guest 5/16" 8mm hose flange. The flange allows you to disconnect the air by simply sliding the blue bushing. The pressure can be monitored using the built-in pressure gauge.

Options

- "Quiet" compressor - source of compressed air

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Continuous mode

- Voltage: 220-230V