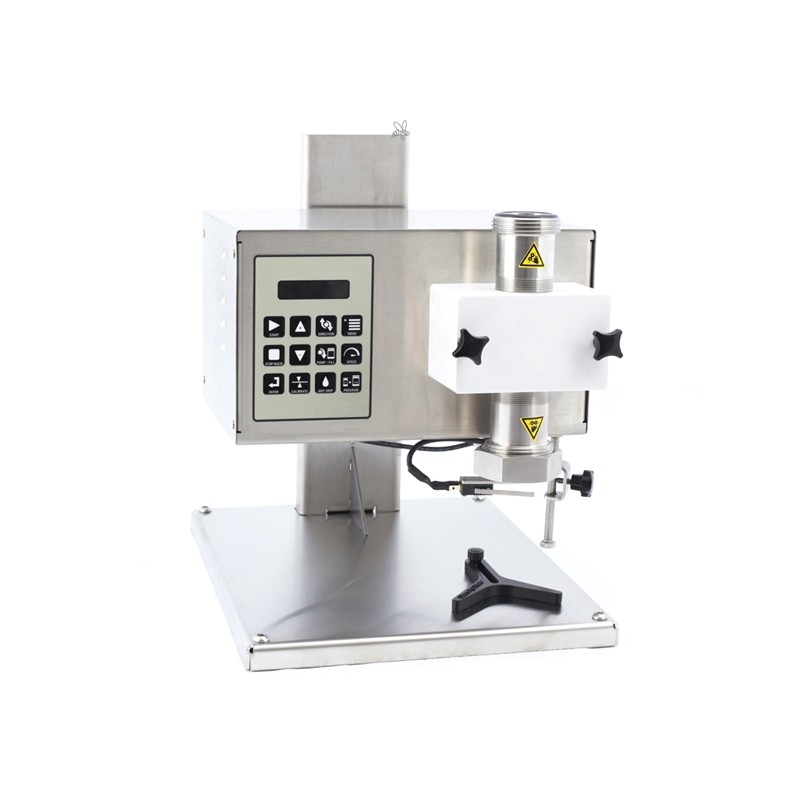

Automatic filling machine DS - 1000

The honey dosing machine is a precise filling machine with a gear pump, it is easy to use and is suitable for filling honey as well as a large number of other different liquids - ranging from thinner ones such as drinking yogurt, to high-viscosity products such as mustard.

- Fast operation

- Easy to use

- Easy to clean

- Accuracy

- Compact design

A complete filling station combined with a filling table in one unit.

Working principle:

The automatic DS-1000 is a filling machine based on a gear pump. A powerful low-voltage DC motor drives the gear pump via a screw gearbox. The motor is controlled electronically. The filling machine has 20 filling programs with settings for weight, calibration factor and other filling parameters. The machine works accurately and is easily programmable for different substances. Just like the pump, the machine works in both directions and can be set to different speeds. All parts that come into contact with the product are made out of food-grade plastic or stainless steel and are easy to disassemble and clean during maintenance.

Empty jars are placed on the table surface and then automatically transported along the rail to the wire switch. As soon as the jar touches the wire switch, the table stops and the filling machine begins to fill the container. As soon as the jar is full, the table starts rotating again until the next jar arrives at the wire switch. The rail is very easy to adjust to different jar sizes.

The filling machine can be adjusted both horizontally and vertically to suit different jar sizes.

Advantages:

- Fast operation - with a filling speed of up to 200 liters per hour, you save a lot of time compared to manual filling.

- Easy to operate - the unit stores 20 programs with different filling parameters, which makes it easy to maintain uniformity of filling from one filling to the next.

- Easy to clean - the computer's drip-proof function keeps the countertop clean, and every part of the machine that comes into contact with your product is made out of food-grade material which is dishwasher safe.

- Accuracy - the machine has a high degree of accuracy.

- Compact - takes up so little space that it can be placed on a regular worktop.

Supplied unassembled. Assembly instructions are included, which usually takes about 30 minutes.

- Productivity: 200 l

A simple mobile filler is an economically advantageous solution for filling barrels. We also offer barrel top filler.

- Material: Stainless steel

This semi-automatic filling machine is used for filling honey as well as other products. We offer many different kinds of filling machines for different applications.

- Material: Stainless steel

- Operation mode: Semi-automatic

The pneumatic piston filler for pastes and liquids is a semi-automatic dispenser designed for dosing various liquids with a low, medium or high viscosity.

- Tabletop compact model

- Includes a built-in 26 l conical storage tank

- A wide dosing range from 300-2500 ml

- Can also be used for products with a high degree of viscosity

- High dosing speed

- Possibility of working in manual or automatic mode

- Material: Stainless steel

- Principle of operation: Continuous mode

- Volume: 300-2500 ml

- Voltage: 220-230V

Keg washing and filling machine used for washing and filling kegs and barrels for beer, cider, wine and other beverages.

- Material: Stainless steel

- Engine power, kW: 0,75

- Operation mode: Manual

- Voltage: 220-230V 380-400V

Filling machine is designed for pumping and filling high viscosity liquids, such as jams, confiture, sauces, dressings, syrups, and like products.

- Productivity: 200ŌĆō600 bottles per hour

- Material: Stainless steel

- Principle of operation: Continuous mode

Semi-automatic dosing machine, designed for filling and capping different spouted pouches with various liquids.

- Material: Stainless steel

- Operation mode: Semi-automatic

Designed for accurate feeding and packaging of liquids under pressure.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 80l/

Semi automatic packaging machine for filling and capping jars.

- Material: Stainless steel

Vibrating conveyors suitable for arranging the product before further processing.

- Working Area Width: 720 mm

- Voltage: 380-400V

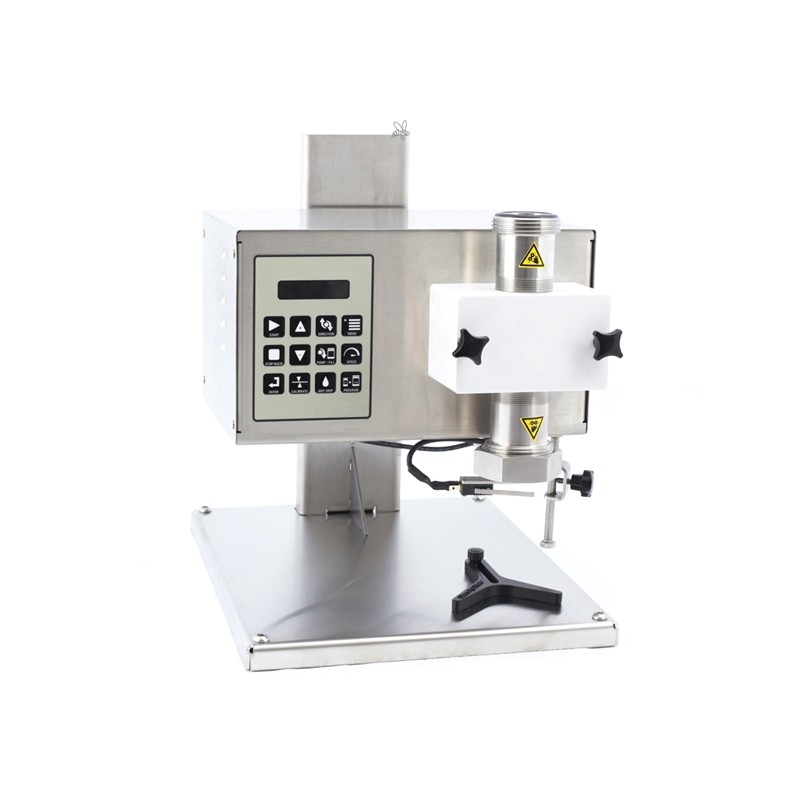

Compact digital filling machine for accurate dosing of viscous liquids such as honey, pastes, sauces, and oils. Designed with food-grade materials, easy-to-clean components, and precise digital control, it is ideal for small production, workshops, and laboratories.

- Operation mode: Semi-automatic

This head capping machine has a magnetic clutch, ribbed spindle. It is semi-automatic and closes bottles or jars with PFP aluminum caps, twist off caps or plastic screws. The price depends on the cap, product you are filling, and capacity.

Price depends on the lid, the product you are filling, and the container.

- Productivity: 400-700 psc/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 220-230V

Chocolate fountain attracts the attention of customers thanks to its stylish design, and can be used to top ice cream cones, to fill cups with hot chocolate drinks etc. Price is for the machine only. You can purchase additional mobile counter, covering rings or various nozzles.

- Material: Stainless steel

- Voltage: 220-230V

Dosing tank for filling and measuring oil designed as an oil reservoir with the ability to adjust the required volume.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l

- Working volume: 80 l

Mechanical vacuum filler, regulated by an electronic system, with a frequency converter.

We offer different hopper capacities.

- Material: Stainless steel

- Operation mode: Automatic

- Country of origin: EU

- Volume: 40/ 90/ 125 / 200l

VBF is a fast, robust, and versatile vacuum bottle filler.┬ĀThis is the filling machine you are looking for if you desire to increase the production volume of your homemade products, and professionalize the bottling of wine, oil, beer, fruit juices, or other products.

- Operation mode: Semi-automatic

- Principle of operation: Continuous mode