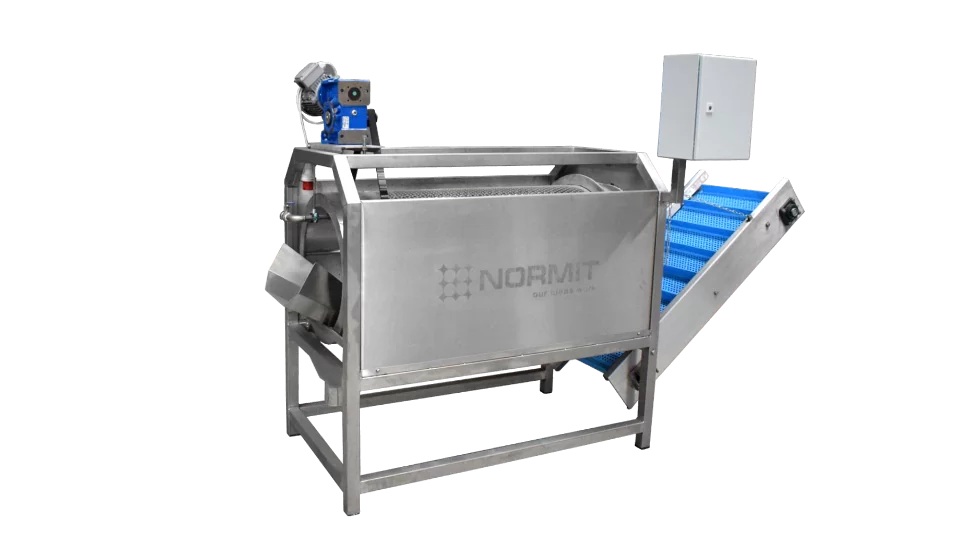

Rotary vegetable washer Drum Wash

The drum washer is designed for washing potatoes and other roots as well as for seeds, nuts and grains.

A washer is an effective solution for washing potatoes, carrots, beets, and other root vegetables, including highly dirty ones with a large amount of soil, clay and other impurities stuck to them.

It is also possible to equip the machine with a fine mesh to wash seeds, nuts, and grains.

The process of vegetable cleaning is carried out through friction between the product and the perforated walls of the drum, or between the vegetables themselves, and also through water rinsing.

Suitable products:

- potatoes

- eggplant

- zucchini

- carrots

- cucumber

- squash

- pumpkin

- radish

- turnip

- beetroot

- artichokes

- pumpkin seeds

- sunflower seeds

- grain

- nuts

- peanuts

How it works

The product is loaded into the washing machine mechanically, then during the washing/cleaning, the product will be brought forward the drum where finally discharge manually or with the help of an optional adjustable conveyor, that can be attached to the washer┬Āand adjusted in height.

Additional options:

- The drum washer can be equipped with an optional discharge conveyor.

- An optional stainless steel mesh sieve around the drum for processing very small products (Fine mesh for seeds, nuts or grains).

- Optional frequency converter to adjust the drum rotation speed (and/or the optional discharge conveyor)

In production lines, the drum washer is used as a machine for preliminary washing, soaking, and separation of dirt and stones (when processing a highly dirty product).

Advantages:

- Stainless steel frame, feet, and drum

- Perforated drum

- The drum has a special shape for easy cleaning

- Variable speed motor-gear unit with an electronic frequency converter

- Infeed and discharge chutes

- As an option -conveyor belt

- filtration and separation from stones and small vegetables

Technical specification:

- Drum drive power, kW: 1.1

- Dimensions (HxWxL): 1900x1150x1680┬Āmm

- Drum diameter x length: 606 x 1420┬Āmm

- Weight:┬Ā311 kg

- Material: Stainless steel

- Engine power, kW: 1,1

- Principle of operation: Continuous mode

- Country of origin: Slovakia

This machine allows washing and sterile rinsing with dry steam of cans and cups before filling them with product.

- Productivity: 6000 psc/h

- Material: Stainless steel

- Principle of operation: Continuous mode

Vegetable washers are designed to clean and prepare vegetables for consumption or further processing.

We offer different types of vegetable washers.

- Material: Stainless steel

- Engine power, kW: 0,47 / 1,45 / 1,85

- Type of the equipment: Individual machine

- Country of origin: EU

- Volume: 160 l/ 300l/ 600l/

We offer different types of washing equipment for various different fruits and vegetables.

- Productivity: 1500 kg/h

- Material: Stainless steel

- Engine power, kW: 3

- Weight: 200

Fruit washer is designed for washing and cleaning products such as fruit or vegetables before processing, especially apples.

If you're looking for any other fruit and vegetable washers, send us a request.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

The destoner lift machine is designed for pre-washing and transporting root vegetables such as potatoes, carrots, beets, and other similar vegetables. After rinsing, the auger destoner separates floating particles like leaves and stems in the receiving hopper, while the product is conveyed up to the discharge height using a screw lift.

- Allows you to separate stones, leaves from root vegetables

- Pre-washing of root vegetable crops

- Two functions in one unit: washing and transporting

- Spacious hopper/tub for loading the product

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Bubble washer for gentle washing and cleaning of fruits and berries, for example peaches, cherries, strawberries and other raw fruits prior to their further processing.┬Ā

- Principle of operation: Continuous mode

- Country of origin: EU

- Working Area Width: 600 mm/ 800 mm/ 1000 mm

This machine is suitable for washing fresh fruits and vegetables. We offer 2 different capacities.

- Productivity: 1000 kg/h/ 3000 kg/h

- Material: Stainless steel

- Engine power, kW: 0,55/ 0,75

- Principle of operation: Continuous mode

- Voltage: 380-400V

The washer with external loading conveyor UNI M is specifically designed for the efficient and high-performance washing of vegetables, potatoes, and fruits, using gentle exposure to water to ensure thorough cleaning without harming the product.

- Material: Stainless steel

The washer-auger-mill machine is designed for washing, transporting and milling whole fruit or vegetable before further processing.

Price depends on your product and the production capacity. For more information, send us a request.

- Productivity: 3000 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

This open tank is intended for washing the juice tanks. Kapacity 250L.┬ĀFor more information, send us a request.┬Ā

- Material: Stainless steel

- Volume: 250l/

The brush washer/scraper is an industrial device for washing and scraping root vegetables depending on the degree of contamination.

- Productivity: 300 kg/h

- Material: Stainless steel

- Engine power, kW: 1

- Voltage: 230 V/ 380-400V

Improve the cleaning process with the CIP-53, a mobile station designed for thorough sterilization and sanitation of vessels and pipelines. Ideal for breweries and the food industry, this comprehensive system with three 50 or 100 liter tanks ensures efficient cleaning of fermentation and storage tanks, offers digital temperature control and neutralization.

- Material: Stainless steel

- Voltage: 380-400V

Clean-in-place (CIP) is a method of cleaning and disinfecting the internal surfaces of pipes, containers, water tanks as well as industrial equipment, filters, related fittings and other accessories without the need for disassembly.

- Material: Stainless steel

- Volume: 2x50 l/ 2x100 l/

The CEP washing machine is a mobile cleaning station designed to efficiently clean various containers, including mixers and boilers, suitable for use in the food, chemical, and pharmaceutical industries.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 85

The washer-elevator-mill machine is designed for washing, transporting and milling whole fruit or vegetable before further processing.

- Productivity: 1000 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

CIP-202: Cleaning-In-Place - Machine for cleaning and disinfecting vessels and pipelines in breweries and other food processing plants with two 200 liter tanks.

- Material: Stainless steel

- Country of origin: EU

- Volume: 200l