Continuous automatic frying oil filter

A filter designed for continuous fine filtration of conveyor fryers using vegetable oil, and other frying fats.

Continuous filtration allows to clean the frying fat/oil from product particles, breading or lezon, which ensures not only the best taste of the product itself, but also a longer oil life.

The oil, after fine filtration through a filter belt, retains its color and taste longer, does not darken, does not discolor after repeated use. Filtration is carried out fully automatically without any participation of the operator. For filtration, a special disposable filter in rolls is used. The used filter material is wound on an empty cardboard roller, which after work is easily dismantled and replaced with a new one.

This equipment is widely used as an additional option to fryers for frying seafood, frozen and chilled semi-finished products. The unit can be used as fine cold or hot oil filtration.

Oil is loaded using an external pump, the filtration temperature depends, first of all, on its type, when using a special pump for hot oil, the operating temperature of filtration can be up to 200 degrees, which allows you to start cleaning the oil almost immediately after frying. With cold filtration - you must wait until the oil cools down.

The principle of filtration is gravitational, when oil is poured through the filter cloth belt due to its own gravity, the filter cloth replaces the conveyor, which carries the decomposition products in the oil from the installation.

The installation is made entirely of stainless steel, the width of the filter cloth is 400 mm.

- Material: Stainless steel

- Operation mode: Automatic

- Type of the equipment: Optional equipment

- Working Area Width: 400 mm

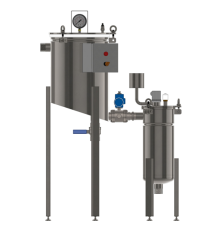

The sorption filter 3000l refers to non-pressure equipment of periodic action for filtering liquids using bulk filtering agents and different sorbents.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Volume: 3000

Hops filters for dry hopping using pellets for seasoning and additional bitter flavour to the beer.

- Material: Stainless steel

- Volume: 60l/

The drum washer is designed for washing potatoes and other roots as well as for seeds, nuts and grains.

- Material: Stainless steel

- Engine power, kW: 1,1

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Flow type magnetic separator for liquid mixtures with a manual cleaning.

- Material: Stainless steel

- Country of origin: Slovakia

Compact and easy to use filtration system for oil is used for the purification of oil which allows to extend it's use.

- Material: Stainless steel

- Type of the equipment: Individual machine

A hot oil filter for continuous industrial tabletop fryers allows you to quickly and effectively filter oil immediately after the frying process.

- Hot oil filtration - oil temperature up to 200 ┬░C.

- Optional filter material - paper, stainless steel

- Material: Stainless steel

- Country of origin: Slovakia

A honey processing machine with preheating and filtering, suitable for industrial honey processing facilities.

- Material: Stainless steel

- Voltage: 220-230V

The AISI 304 stainless steel oil drain system is suitable for use with most deep fryers. It allows you to filter the oil directly when draining it from the fryer.

- Material: Stainless steel

- Weight: 13,5

Strainer filter protect product or production machines from mechanical damage, keep undesirable particles away from your product to help to prevent production downtimes.

- Material: Stainless steel

- Country of origin: EU

Honey filter - an effective solution for filtering honey from various inclusions and impurities at an industrial scale.

- Material: Stainless steel

- Type of the equipment: Optional equipment

Flow frying oil filter CFC offers a combined solids recovery option, as well as additional filtration support.

- Material: Stainless steel

- Principle of operation: Continuous mode

The rotary drum cooler is designed for efficient pre-cooling, stopping the cooking process, and cooling of boiled, blanched, fried, baked, or thermally processed foods. The rotating perforated drum ensures uniform cooling together with the additional water supply.

- Uniform cooling

- Adjustable drum speed

- Made entirely out of stainless steel

- Suitable for a wide range of food products

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 1,1

The cyclone dust collection system is ideal for food processing facilities looking to prevent contamination by airborne particles, reduce product loss, and maintain a cleaner work environment.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 220-230V

Electric continuous flow heaters in different designs and performance parameters.

- Heating: Electricity

- Material: Stainless steel

- Country of origin: Slovakia

- Type of pump: sealless pump

The cyclone filter effectively separates particles and contaminants from air or gas streams, ensuring product quality and maintaining equipment efficiency, particularly important in the food industry.

- Material: Stainless steel

- Volume: 150l

Compact food filtration equipment with 12 filtering units. Unique filtration purifies products to very high standard- all materials used are perfectly compatible with liquids for human consumption.

- Engine power, kW: 0,34

- Principle of operation: Continuous mode

- Weight: 16