Oil drainage and filtration system

The AISI 304 stainless steel oil drain system is suitable for use with most deep fryers. It allows you to filter the oil directly when draining it from the fryer.

With the drain system, you can easily filter the oil out from the fryer right as you're draining it from the working tank into a storage container.

Made entirely out of AISI 304 stainless steel, it consists of a removable filter mesh, a 1" M stainless steel AISI 304 ball valve, 4 wheels, 2 of which rotate, equipped with a brake, and a stainless steel handle for easy carrying.

The basic set includes:

- Removable filter mesh

- 4 wheels, 2 of which rotate and have a brake

- 50 l container

- Stainless steel carrying handle

- Material: Stainless steel

- Weight: 13,5

You might also like

We offer different capacity grease and oil traps.

- Material: Stainless steel

- Engine power, kW: 1,5 /

Electric continuous flow heaters in different designs and performance parameters.

- Heating: Electricity

- Material: Stainless steel

- Country of origin: Slovakia

- Type of pump: sealless pump

Compact and easy to use filtration system for oil is used for the purification of oil which allows to extend it's use.

- Material: Stainless steel

- Type of the equipment: Individual machine

The price is set for the basic fryer version without additional modules. If purchasing the fryer together with both of the additional conveyor modules ŌĆō the double conveyor fryer and the paddle conveyor fryer ŌĆō we offer a discount of 300 EUR.

The versatile modular conveyor fryer with a single conveyor belt is used for the continuous frying of a variety of products with a low moisture content, that do not require forced immersion beneath the surface of the oil for even frying.

- Adjustable frying time from a few seconds up to an hour!

- Ability to use the unit as a continuous blancher or boiler for cooking products with a delicate structure

- Modular system, expanding functions with each new module

- Compact, desktop version

- Possibility of periodic frying of products with automatic unloading

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Oil volume: 60l

- Voltage: 380-400V

In the production of condensed milk, a refractometer is used to accurately determine the solids content of the product, which is essential for meeting production standards and ensuring compliance with legal regulations.

- Type of the equipment: Optional equipment

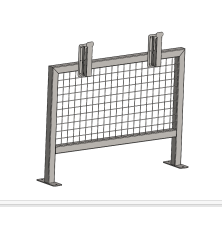

This rack is typically used as car mat holders at car washes. It can also serve as a universal stand for use in other enterprises.

- Material: Stainless steel

The working surface is made out of food-grade stainless steel, on top of which the deep fryer can be installed. It is quipped with wheels for ease of movement.

- Material: Stainless steel

Set of 4 height adjustable legs+/- 100 mm.

- Material: Stainless steel

- Type of the equipment: Optional equipment

A hydraulic crane hoist with a hook is a mechanical device designed to lift and move heavy machinery or engines, commonly used in industrial settings as well as automotive repair for safe and efficient handling of heavy loads.

- Type of the equipment: Optional equipment

The durable single gas stove serves a versatile purpose, suitable for heating large cooking kettles. 7 kW.

- Heating: Gas

- Heating power, kW: 7

A thermometer is a precision tool used to measure product temperature in food processing, ensuring accurate control during cooking, mixing, and other food production processes. It helps to maintain consistency, optimize processing conditions, and meet safety standards in industrial food processing equipment like cooking kettles, blanchers and fryers.

- Material: Stainless steel

- Type of the equipment: Optional equipment

Compact, reliable, and easy to use. The frequency converter ensures smooth starting and stopping of the device's motor, reducing inrush currents, and adjusting the motor speed. It can also be connected to your smartphone via Bluetooth for convenient configuration and parameter adjustment.

Key benefits:

- Precise digital control at the touch of a button.

- Application macros.

- Switch between Industrial, Pump, and Fan modes for optimized operation.

- It is used and mounted directly on the equipment, eliminating the need for electrical cabinets. It can also be wall-mounted.

We also offer programming and installation of the frequency converter to ensure seamless integration and optimal functionality for your equipment.

- Type of the equipment: Optional equipment

Compact and powerful gas stove with 3 rings designed for the connection to standard LPG cylinders. Ideal for heating large volumes of liquid, cooking soups or sauces in cooking kettles, and maintaining meal temperatures during preparation or service. The sturdy, open-frame design ensures excellent stability and high load capacity for everyday use in catering and food processing.

The set consists of 20 shelves from AISI304 stainless steel.┬ĀAdditional option for MAK DRYER 7-14.

- Material: Stainless steel

- Type of the equipment: Optional equipment

Additional option for the VMG laboratory vacuum homogenizer 20/50.

- Type of the equipment: Optional equipment

A set of additional paddles for transporting and unloading the product from the working area of ŌĆŗŌĆŗthe universal 400/1100/12 fryer.

A large three-section basket for vacuum fryers, cooking kettles and other batch processing equipment.

- Material: Stainless steel

- Type of the equipment: Optional equipment

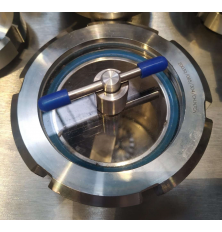

A hot oil filter for continuous industrial tabletop fryers allows you to quickly and effectively filter oil immediately after the frying process.

- Hot oil filtration - oil temperature up to 200 ┬░C.

- Optional filter material - paper, stainless steel

- Material: Stainless steel

- Country of origin: Slovakia

A frequency converter is an electrical device that adjusts the frequency of an input power source to control the speed and torque of electric motors, commonly used in industrial applications like pumps, fans, and conveyor systems.

- Power: 0.75 kW

- Input Voltage: 1 phase, 230 V, 50/60 Hz

- Rated Output Current: 4.5 A

- Output Frequency: 0 to 999.9 Hz

- Protection Rating: IP65

- Type of the equipment: Optional equipment

- Voltage: 380-400V

Stainless steel baskets for cooking kettles, autoclaves, pasteurizers.

- Material: Stainless steel

- Principle of operation: Batch mode