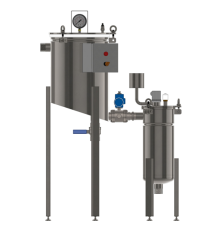

Cyclone dust collector

The cyclone dust collection system is ideal for food processing facilities looking to prevent contamination by airborne particles, reduce product loss, and maintain a cleaner work environment.

Cyclone Dust Collection System for Food Processing Applications

A cyclone suction system is a high-efficiency dust removal solution designed for the food industry, where fine, powdery ingredients can become airborne during processing. The cyclone dust collector has a dual-stage filtration system, it effectively captures and separates dust particles, ensuring cleaner air and improved hygiene in production environments. The built-in filter ensures that the air is purified, while the collected dust is stored in an easy-to-empty container.

Ideal for Processing Powdered Foods

This cyclone dust collector is particularly beneficial for facilities handling finely milled or lightweight food powders, such as:

- Flour & starches (wheat flour, cornstarch, rice flour)

- Dried dairy products (milk powder, whey protein, casein)

- Ground spices & seasonings (paprika, cinnamon, cocoa powder)

- Sugar & sweeteners (powdered sugar, dextrose)

- Nutritional supplements (plant-based protein powders, vitamin blends)

These types of ingredients are prone to becoming airborne during mixing, grinding, sifting, or packaging, leading to potential cross-contamination, product loss, and increased cleaning efforts. The Cyclone Extraction System helps mitigate these issues by efficiently capturing and collecting fine particles before they spread through the production area.

How the Cyclone Filtration Works

The system utilizes a cyclonic separation process to remove dust before the air reaches the primary filter:

- Cyclone Chamber: As dust-laden air enters, a high-speed circular airflow forces heavier particles toward the walls, where they lose momentum and fall into a collection bin.

- Primary Filtration: Finer dust that remains suspended is captured by a high-efficiency filter, preventing it from entering the work environment.

- Clean Air Output: The purified air is then safely expelled, reducing airborne contamination and improving overall air quality.

Features & Benefits

- Dual-Stage Filtration ŌĆō Combines cyclonic separation with a high-efficiency filter.

- Easy Dust Collection & Disposal ŌĆō Collected material is stored in a removable container.

- Designed for the Food Industry ŌĆō Prevents contamination and ensures a clean work environment.

- Efficient Dust Collection ŌĆō Compact design with a 550 W motor and an airflow rate of 15 m┬│/min.

- Versatile Applications ŌĆō Ideal for bakeries, spice grinding facilities, powder processing, and dry food packaging lines.

Technical Specifications

- Airflow Capacity: 15 m┬│/min

- Suction Power: 2.9 kg/h

- Filter Dimensions: 320 ├Ś 600 mm

- Filtration Area: 4.42 m┬▓

- Minimum Particle Size Captured: 8 ╬╝m

- Power Consumption: 550 W

- Electrical Connection: 230 V

- Dimensions (W├ŚH├ŚD): 590 ├Ś 1165 ├Ś 480 mm

- Weight: 36 kg

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 220-230V

You might also like

Convective rotary drum dryers are used for drying granular, loose and bulk materials. They can be used for drying salt, coffee, various granules, powders, grain, nuts, seeds, fruit/vegetable bagasse, and many other products. When used in other industries, the dryer allows for the drying of salt, sand, expanded clay granules, and other similar non-flammable substances. For more information, send us a request.

The drum dryer can be configured to operate with either electric heating or gas heating (which can offer a lot more power), depending on your specific requirements and preferences.

Warning: It is not recommended to use the gas heating option for drying substances that are highly flammable, as doing so could pose a significant fire risk.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Flow type magnetic separator for liquid mixtures with a manual cleaning.

- Material: Stainless steel

- Country of origin: Slovakia

Hops filters for dry hopping using pellets for seasoning and additional bitter flavour to the beer.

- Material: Stainless steel

- Volume: 60l/

The sorption filter 3000l refers to non-pressure equipment of periodic action for filtering liquids using bulk filtering agents and different sorbents.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Volume: 3000

Honey filter - an effective solution for filtering honey from various inclusions and impurities at an industrial scale.

- Material: Stainless steel

- Type of the equipment: Optional equipment

A honey processing machine with preheating and filtering, suitable for industrial honey processing facilities.

- Material: Stainless steel

- Voltage: 220-230V

A hot oil filter for continuous industrial tabletop fryers allows you to quickly and effectively filter oil immediately after the frying process.

- Hot oil filtration - oil temperature up to 200 ┬░C.

- Optional filter material - paper, stainless steel

- Material: Stainless steel

- Country of origin: Slovakia

The cyclone filter effectively separates particles and contaminants from air or gas streams, ensuring product quality and maintaining equipment efficiency, particularly important in the food industry.

- Material: Stainless steel

- Volume: 150l

Flow frying oil filter CFC offers a combined solids recovery option, as well as additional filtration support.

- Material: Stainless steel

- Principle of operation: Continuous mode

Compact and easy to use filtration system for oil is used for the purification of oil which allows to extend it's use.

- Material: Stainless steel

- Type of the equipment: Individual machine

The AISI 304 stainless steel oil drain system is suitable for use with most deep fryers. It allows you to filter the oil directly when draining it from the fryer.

- Material: Stainless steel

- Weight: 13,5

The rotary drum cooler is designed for efficient pre-cooling, stopping the cooking process, and cooling of boiled, blanched, fried, baked, or thermally processed foods. The rotating perforated drum ensures uniform cooling together with the additional water supply.

- Uniform cooling

- Adjustable drum speed

- Made entirely out of stainless steel

- Suitable for a wide range of food products

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 1,1

Strainer filter protect product or production machines from mechanical damage, keep undesirable particles away from your product to help to prevent production downtimes.

- Material: Stainless steel

- Country of origin: EU

Electric continuous flow heaters in different designs and performance parameters.

- Heating: Electricity

- Material: Stainless steel

- Country of origin: Slovakia

- Type of pump: sealless pump

Compact food filtration equipment with 12 filtering units. Unique filtration purifies products to very high standard- all materials used are perfectly compatible with liquids for human consumption.

- Engine power, kW: 0,34

- Principle of operation: Continuous mode

- Weight: 16

The drum washer is designed for washing potatoes and other roots as well as for seeds, nuts and grains.

- Material: Stainless steel

- Engine power, kW: 1,1

- Principle of operation: Continuous mode

- Country of origin: Slovakia

A filter designed for continuous fine filtration of conveyor fryers using vegetable oil, and other frying fats.

- Material: Stainless steel

- Operation mode: Automatic

- Type of the equipment: Optional equipment

- Working Area Width: 400 mm