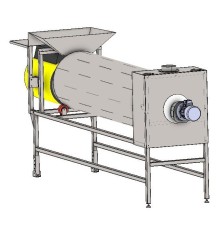

Rotary drum cooling machine

The rotary drum cooler is designed for efficient pre-cooling, stopping the cooking process, and cooling of boiled, blanched, fried, baked, or thermally processed foods. The rotating perforated drum ensures uniform cooling together with the additional water supply.

- Uniform cooling

- Adjustable drum speed

- Made entirely out of stainless steel

- Suitable for a wide range of food products

The rotary drum cooler is an effective solution for quickly reducing the temperature of foods after boiling, blanching, frying, or baking.

The inclined rotating drum gently moves the product, allowing it to cool evenly during rotation, removing excess heat and surface moisture. Depending on requirements, the unit can operate with cold or iced water and can be equipped with a fine-mesh screen for fine-grained products such as grains, legumes, and others.

Cooling is achieved by circulating water in a rotating drum. This makes the drum cooler ideal for stabilizing product quality, cooling faster, stopping thermal processes, preserving texture, and preparing the product for packaging or further processing.

Ideal for cooling vegetables and plant-based products after blanching and cooking, such as:

|

|

|

|

|

|

|

|

|

As well as protein products:

|

|

|

|

|

|

|

|

|

|

|

|

And other products requiring rapid stabilization after heat treatment.

Advantages

- The frame, drum, and legs made entirely out of stainless steel

- Perforated drum optimized for rapid heat dissipation

- Drum geometry ensures smooth yet efficient product movement

- Drum speed adjustment via an electronic frequency converter

- Inlet and outlet chutes included

- Optional discharge conveyor for a smooth workflow

- Efficient water use and additional filtration for recirculation

- Capable of cooling both large and small batches

Basic version

Includes a stainless steel frame supporting a perforated drum with a drive. The unit is equipped with a water inlet and outlet system, the drum angle can be adjusted by adjusting the height of the support structure's legs to control the speed of product flow through the cooler.

Operating principle

Product is fed into the rotating drum manually or via an optional inlet conveyor. As the drum rotates, the product is gently mixed and moved to the discharge outlet. Cold water is supplied to the unit, which, after spraying the product through a perforated drum, flows out into a drain for disposal.

The cooled product is unloaded manually or using an optional height-adjustable conveyor. Continuous water exchange ensures consistent cooling efficiency, while perforations allow warm water and excess surface moisture to drain away.

Technical specifications

- Drum drive power: 1.1 kW

- Dimensions (H x W x D): 1900 x 1150 x 1680 mm

- Drum diameter x length: 606 x 1420 mm

- Weight: 311 kg

Additional options

- Optional infeed/outfeed conveyor (height-adjustable)

- Fine-mesh stainless steel insert for small products (peas, grains, small pasta, nuts)

- Variable frequency drive for drum speed control

- Water spray system (spray bar)

- Water recirculation and filtration system

- Full integration into cooling or blanching lines

The unit is also offered as a fruit and vegetable washing machine or as a drum filter for separating small particles.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 1,1

You might also like

Air cooling conveyor with MULTI AIR KNIFE is a system for┬Ā intensive┬Āremoving excess water or oil and preliminary cooling.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 500 mm

Convective rotary drum dryers are used for drying granular, loose and bulk materials. They can be used for drying salt, coffee, various granules, powders, grain, nuts, seeds, fruit/vegetable bagasse, and many other products. When used in other industries, the dryer allows for the drying of salt, sand, expanded clay granules, and other similar non-flammable substances. For more information, send us a request.

The drum dryer can be configured to operate with either electric heating or gas heating (which can offer a lot more power), depending on your specific requirements and preferences.

Warning: It is not recommended to use the gas heating option for drying substances that are highly flammable, as doing so could pose a significant fire risk.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Lowering the temperature and humidity protects the product even without chemical treatment. The device is also used for continuous air cooling after heat treatment.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The modular cooling conveyor is produced as a standard tabletop version with a section length of 1000 mm; in addition to it, you can order a stainless table or a frame supporting structure. The air cooling conveyor can be sectionally increased in length by the required number of sections.

- Compact, easy to install on any work surface

- Features a fine-grained stainless steel mesh for high temperatures and small-sized products

- Easily combined in line with a tabletop fryer 400/1100/12

- Easy maintenance and cleaning

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Width: 400 mm

Milk cooler tank designed for cooling milk and other dairy products. The tank is available in 13 different capacities, covering a range from 50 liters all the way up to 2,500 liters, capable of meeting the needs of all dairy & cheese production facilities. We offer 2 or 4 milking options. Prices are displayed for the milk cooling tank with 4 milking.

- Material: Stainless steel

- Principle of operation: Batch mode

ACM mixing tank is intended for efficient cooling, heating, tempering and storing of mayonnaise, sour cream, chocolate, oil and similar products after their production.

- Material: Stainless steel

- Principle of operation: Batch mode

The new line of TCAEY compact cooling units is suitable as a cooling source for industrial applications. It's a reliable chilling device for cooling┬Ādifferent kinds of liquids.┬Ā

- Principle of operation: Continuous mode

- Country of origin: EU

Vacuum homogenizer VMG M is the ideal solution for the production of pilot batches and the industrial production of a wide range of products of small and medium production. The price depends on the production capacity.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Max vacuum: -0,8 Bar

- Working volume: 50-80l

CAC Air cooling conveyors are designed for intensive cooling and removal of excess water or oil (air knife section) from products after frying, cooking or blanching.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 500 mm

- Voltage: 380-400V

Cooling tunnel with a length of 15.2 meters. The standard design consists of 13 sections with removable top. For more information, send us a request.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Width: 400 mm

The modular cooling conveyor is produced as a standard tabletop version with a section length of 1000 mm; in addition to it, you can order a stainless table or a frame supporting structure. The air cooling conveyor can be sectionally increased in length by the required number of sections.

- Compact, easy to install on any work surface

- Features a fine-grained stainless steel mesh for high temperatures and small-sized products

- Easily combined in line with a tabletop fryer 400/1100/12

- Easy maintenance and cleaning

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Width: 400 mm

Lowering the temperature and humidity protects the product even without chemical treatment. The device is also used for continuous air cooling after heat treatment.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

An air cooling conveyor is used to rapidly cool products in food processing industries by circulating cool air over them as they move along a conveyor belt. This efficient cooling process helps preserve product quality and reduce the time between processing stages, facilitating smoother production workflows.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

Heating: electric and steam - combination

- Material: Stainless steel

- Principle of operation: Continuous mode

A chiller is a cooling machine that removes heat from a liquid through vapor compression and absorption in a cyclic manner.

- Principle of operation: Continuous mode

- Cooling performance l/h: 100 / 200 l/ 300

Air cooling conveyor with MULTI AIR KNIFE is a system for┬Ā intensive┬Āremoving excess water or oil and preliminary cooling.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 500 mm

It is intended for pre-cooling after cooking or frying vegetables and fruit, meat, fish and seafood and other products.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 600 mm

The vacuum crystallizer-cooler is specifically designed for sweetened condensed milk. Crystallization with cooling is one of the most important stages in the production of condensed milk according to GOST and is necessary before dosing and packing the finished product.

- After crystallization, condensed milk has a delicate structure with small crystals

- Condensed milk has a homogeneous shape and attractive consumer properties

- The shelf life of condensed milk is extended without changing the quality of the product

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 300l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

An air cooling conveyor is a system that uses moving belts and airflow to cool down products as they are transported along the conveyor line.

For additional information or a price quote, send us a request.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Width: 500 mm

The stated price does not include the steam generator

The unique sectional cooking kettle is intended for high-performance cooking/blanching/frying of a wide range of products with subsequent cooling to avoid damaging their structure. An essential part of this technology is the efficient cooling section, necessary for halting the cooking process after unloading. This function is also necessary when processing vegetables to the "aldente" state, when vegetables retain their structure and natural color after thermal treatment. This model provides heating by direct injection of purified steam into the heating section (steam generator - option).

- Suitable for cooking small-sized products

- Fast and intense heating due to direct steam injection

- Intensive hydro-stirring

- Automatic basket lifting system

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 2x250l/ 3x250l

- Voltage: 380-400V

- Working volume: 2x175l/ 3x175l