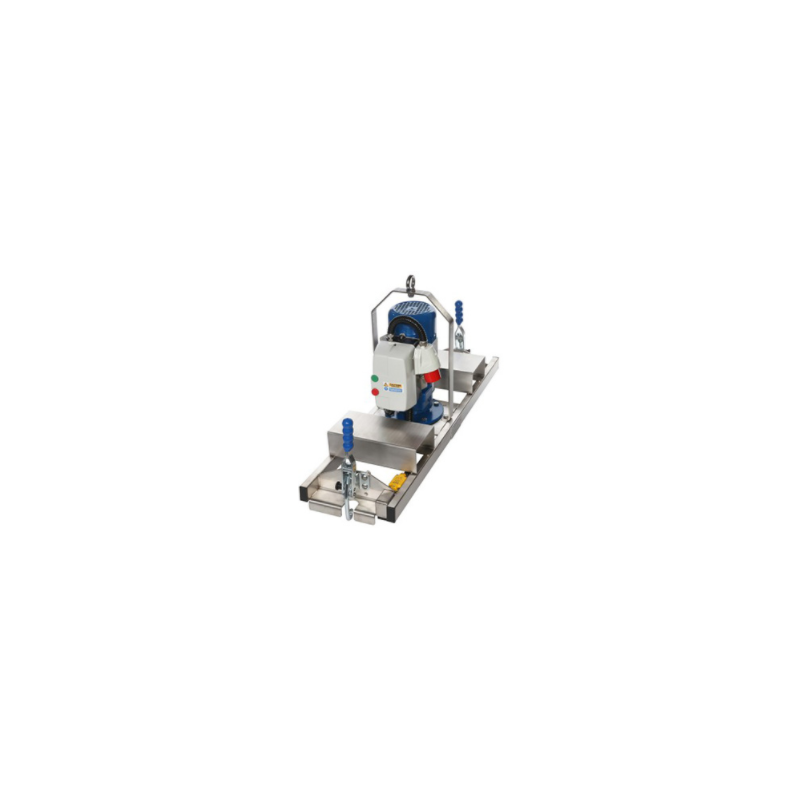

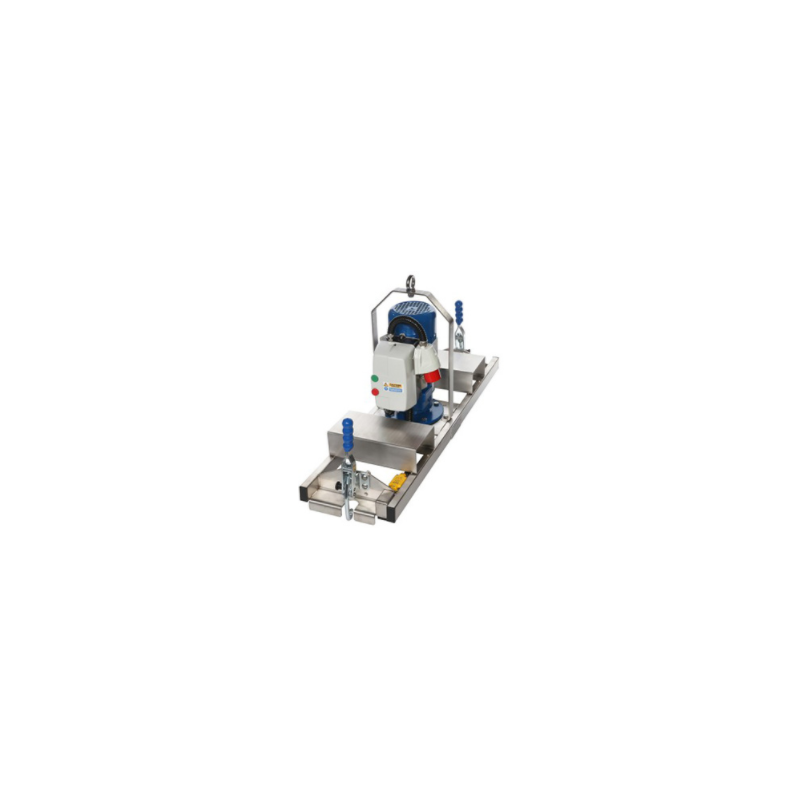

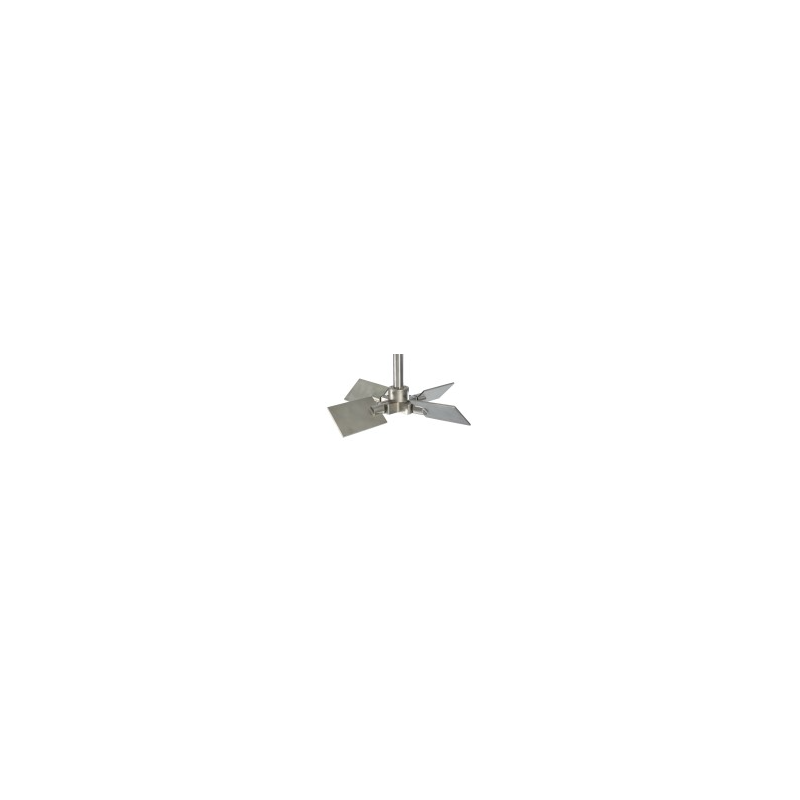

Barrel mixer 200 L

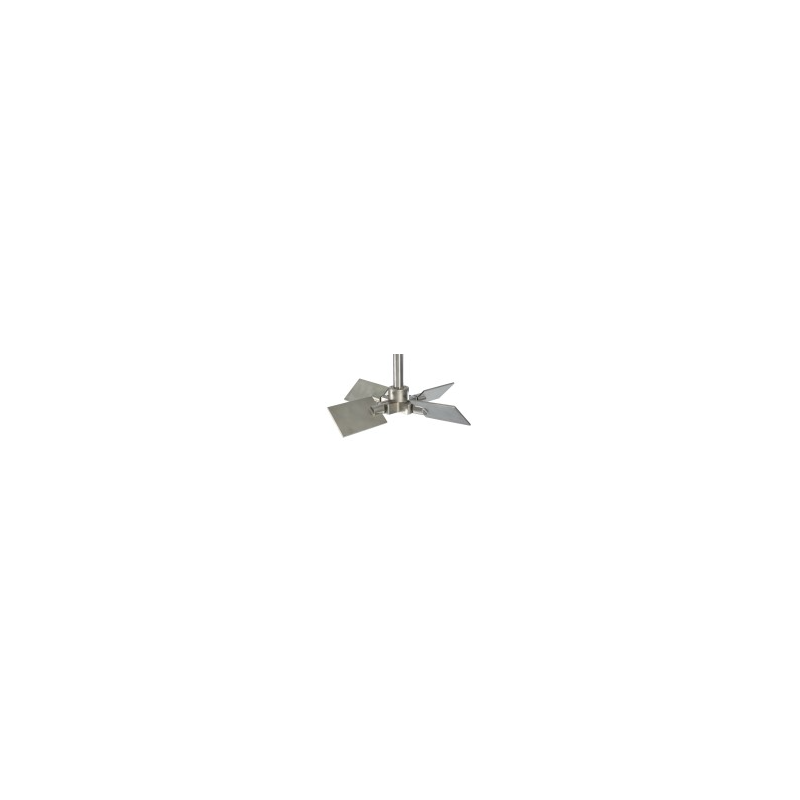

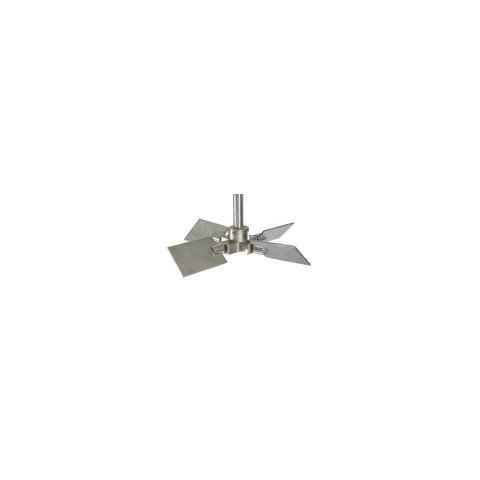

The appropriate mixing equipment for drum processing depends upon the properties of the products and with the available drum opening.

Barrel mixer/ Agitator provide an efficient cost-effective solution for product that need to be mixed before use.

Impellers have been developed for a wide range of application including blending viscous liquids, it can be used for dispersing powders.

Features

- Fully CE compliant

- Factory fully tested

- Different avaible type for lifting

Applications

A wide range of industries use product supplied in barrel that needs to be mixed before use to achieve consistent performance and quality including.

- Chemical Industries

- Inks

- Adhesives

- Paint and varnish

- Cosmetics industry

- Water treatmend chemicals

- Food and beverages

NOTICE: Atex certified mixers are supplied without a starter for wiring ib site but can be optionally supplied with ATEX safety Switch

- Type of the equipment: Individual machine

- Voltage: 230 V/ 380-400V

Industrial churning machine available in two capacities. Simple production of butter.

- Geometric volume: 30 l/ 70 l

This is a 400 l capacity heating boiler, we offer different capacity commercial cooking boilers.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 25

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 400l

- Voltage: 380-400V

The industrial planetary mixer is mainly used in the confectionary industry. Available in three different sizes: 120, 140 and 170 L.

- Engine power, kW: 5,5

- Voltage: 380-400V

Universal cooking kettle with a built-in mixer, used for cooking and stirring a variety of food products, cosmetic emulsions, creams and much more.

- Easily removable self-adjusting scrapers

- Lid opening sensor for safe stirrer maintenance

- Hygienic temperature sensor for the product

- Large diameter outlet valve

- Safe steam outlet on top of the boiler lid

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

The coating machine is designed for uniform application, impregnation of oil and fat mixture, dyes and flavors, enzymes, vitamins and other additives, various products with a high level of hygiene.

- Material: Stainless steel

- Engine power, kW: 2,2

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 281 kg

- Volume: 500l

The home cheese making unit is a simple and compact solution for producing homemade cheeses right in your kitchen or for small-scale food production, it can also be used as a laboratory unit for testing new cheese recipes in industrial factories. The unit is designed for processing milk and producing various cheeses and cheese-based products.

- Options to choose electric or gas heating (additional options)

- Special stirrer for automatic mixing, which prevents possible burning of milk

- Visual control during operation thanks to a special safety grid on the upper sectional opening hatch

- Quick-release lid with a stirrer for easy unloading of the product or cleaning of the unit

You can also choose a version of the cooking kettle with a thermometer and an outlet valve, making it suitable for milk pasteurization as well.

- Material: Stainless steel

- Engine power, kW: 0,12 0,18/ 0,25

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Diameter, mm: 400/ 500/ 600

Homogenizer for the production of whipped cream, ice cream, and much more. It allows you to obtain stable liquid emulsions of food mixtures.

- The homogenizer can be installed directly into the container with the product

- High productivity - in just 8 minutes, it is possible to whip up to 60 liters of milk mixture

- The peripheral speed of the knives is 16 m/s

- Material: Stainless steel

- Engine power, kW: 0,37/ 2,2

- Country of origin: EU

- Voltage: 380-400V

A vacuum diffuser is a device used in the food industry to remove oxygen from a product under vacuum conditions, primarily employed for enhancing the preservation of food by reducing oxidation and extending shelf life.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Volume: 200l/ 1000l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Suitable for mixing a small amount of dough or meat as well as other thick mixtures.

- Material: Stainless steel

- Engine power, kW: 0,55

- Principle of operation: Batch mode

- Volume: 10l/ 20l

A vacuum evaporator is a device used to evaporate liquids at lower temperatures by creating a vacuum environment, which reduces the boiling point of the liquid and enables efficient evaporation without thermal degradation of sensitive materials. Working volume up to, l: 1900 l.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: up to 1900 l

This versatile 300 liter planetary mixer is a professional food processing equipment used for mixing, kneading, and blending ingredients in various culinary applications. It features a unique mixing action where the beater rotates on its axis while also revolving around the bowl, ensuring thorough and consistent mixing of ingredients.

A rotating drum unit designed for continuous coating and seasoning operations as well as product saturation with spices and flavor additives, utilized in production lines for chips, snacks, and various semi-finished products.

- Adjustment of the Drum Tilt Angle

- Hygienic design and execution: mirror-polished inner surface of the drum

- Various blade options for gently turning the product (optional)

- Dispensers for dry and wet flavorings (optional)

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 0,25

- Voltage: 380-400V

The vacuum cooking and mixing tank is used to boil products at low temperatures, which helps preserve the natural color, taste and nutrients in the product.

Vacuum equipment is used for cooking premium-quality jams, sauces, fruit and vegetable concentrates.

- Inclined design

- Efficient emptying

- High hygiene standards

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

Grinding mill for continuous grinding of meat and ingredients such as seeds, small bones and cartilages that are unwanted in the final product.

- Engine power, kW: 3

- Principle of operation: Continuous mode

- Voltage: 380-400V

ACM mixing tank is intended for efficient cooling, heating, tempering and storing of mayonnaise, sour cream, chocolate, oil and similar products after their production.

- Material: Stainless steel

- Principle of operation: Batch mode

Butter churner with a volume of 50 L and a usable volume of 25 L for the traditional production of butter from cream.

- Material: Stainless steel

- Engine power, kW: 0,55

- Geometric volume: 50 l