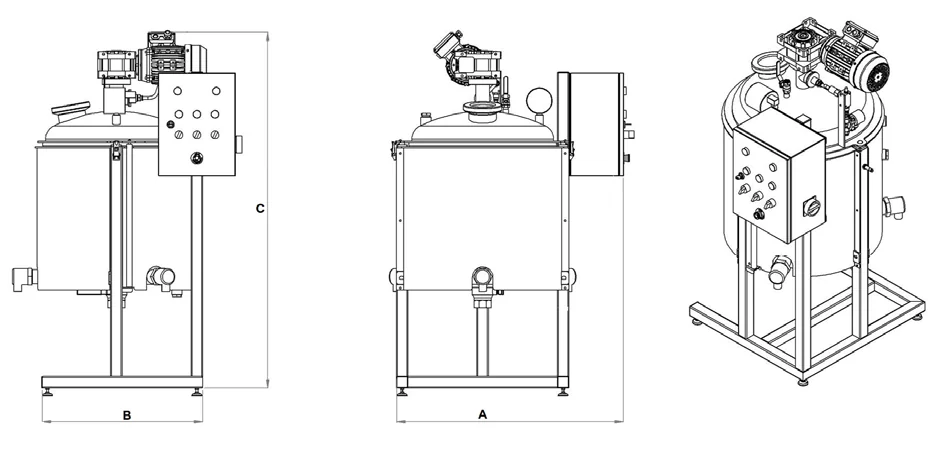

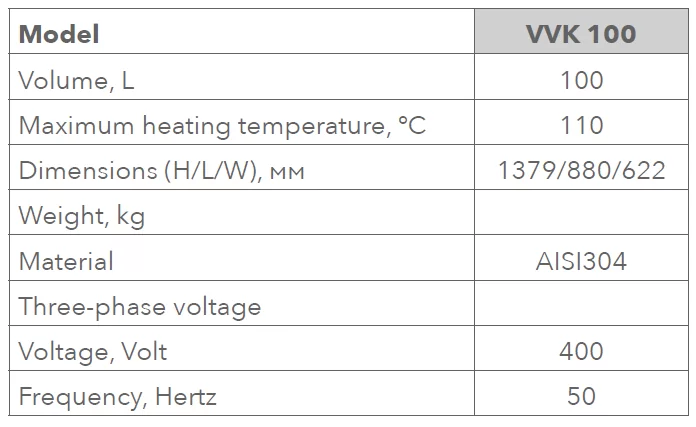

Vacuum cooker VVK 100

A Vacuum cooker is a versatile device used in culinary settings to cook food under vacuum conditions, enhancing flavors and textures while also reducing cooking times.

We offer various different cookers.

Cooking under vacuum allows you to cook with lower temperature which guarantees healthier products that retain its nutrients and flavor.

Suitable products:

- mayonnaise

- ketchup

- sauces

- jams

- many other products

Maximum retainment of vitamins

The Normit VVK Vacuum Cooker is a batch cooking equipment with heating and cooling jacket, a low-atmospheric pressure heating system that allows maximum retainment of beneficial substances and vitamins in processed products at minimum heat costs. The cooker is equipped with a special frame mixer with Teflon scraper, which allows processing of products with low or medium viscosity.

The VVK cooking kettle consists of:

a boiler with heating / cooling jacket on the load-bearing structure, equipped with a special mixer, heating system, vacuum system and control panel.

Universal use in many industries

The device is intended for use in sectors such as pharmaceutical, chemical, food and cosmetics, etc. The vacuum cooker may be equipped with a hopper and inlet shafts. There is a drain on the bottom of the product that removes the product.

What are the advantages of vacuum cooking?

The vacuum cooking technique can be used for any food product, which is cooked in a hermetically sealed environment and in its own juices, which preserves its natural flavor. It also greatly reduces loss of weight and volume, helps to keep aromas fresh and lengthens the shelf life of the food.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 380-400V

You might also like

The vacuum homogenizer is designed for whipping mayonnaise, ketchup, various sauces, confectionery pastes and fillings, condensed milk, jams and marmalades, canned goods, as well as similar liquid or pasty products with a homogeneous structure.

- Homogenizer in an external circulation loop

- Built-in vacuum generation and retention system

- Modular design with numerous options

- Possibility of automatic dosing of ingredients (optional)

- No additional pump required for loading/unloading

- Automatic top cover lifting system

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 13,5

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The vacuum cutter is intended for large processing enterprises dealing in the confectionery, fruit and vegetable processing industries. They are intended for processing food down to a homogenous mixture with minimal air content.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Voltage: 380-400V

Specialized vacuum cooking kettle for sweet masses, ideal for commercial applications and medium to large scale food production.

For a price quote, send us a request.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 200l

- Dimensions, mm: 2055x1800x1980

It is ideal for cooking jams, marmalades, syrups, sauces, creams and other products.

Price depends on the chosen option.┬Ā

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 300l

- Geometric volume: 350 l

Double-jacket stainless steel cooker for marmalade and jam production.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24

- Principle of operation: Batch mode

- Volume: 100l/ 200l/ 300l

- Voltage: 380-400V

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

We offer different types of vacuum evaporation machines, this type is an affordable option for efficient evaporation in a stainless steel unit.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l

The VMG S 650P vacuum homogenizing unit can be used for making toothpaste as well as a variety of similar products with complex production requirements.

- The vacuum ensures effective air removal, eliminating the conditions for the development of bacteria and other pathogenic organisms.

- The special shape of the mixing device is tailored for the thickest and most viscous products.┬Ā

- The Ultra Shear submersible homogenizer creates a stable emulsion.

- The cavitation processes aid in activating hydrodynamic mixing.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 29

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 52

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The vacuum homogenizer is designed for whipping mayonnaise, ketchup, various sauces, confectionery pastes and fillings, condensed milk, jams and marmalades, canned goods, as well as similar liquid or pasty products with a homogeneous structure.

- Homogenizer in an external circulation loop

- Built-in vacuum generation and retention system

- Modular design with numerous options

- Possibility of automatic dosing of ingredients (optional)

- No additional pump required for loading/unloading

- Automatic top cover lifting system

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 13,5

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

This electric cooking pot has a volume of 60 liters and is used to prepare a large number of dishes. It is comfortable to use and easy to clean.

- Material: Stainless steel

- Volume: 60l/

- Voltage: 380-400V

The compact line of double-type vacuum cooking kettles comprises a complex of batch food cooking units designed for periodic thermal processing, vacuum mixing, and deaeration of various products under sub-atmospheric pressure.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 2x300l/ 2x600l

Chocolate heating pump is the perfect solution to upgrade your production line. You can easily connect the pump to any device (such as a chocolate enrobing machine).

- Principle of operation: Batch mode

- Voltage: 380-400V

MP cooker is a reliable and extremely functional solution for cooking, pasteurizing in the same tank thus saving equipment cost, space. All material are most reliable in European market so guarantee a long and trouble free operation

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

The price is indicated with a semi-automatic control panel

The vacuum cooking kettle is designed for use in public catering establishments (restaurants, hotels, catering companies) and small manufacturing businesses. This equipment enables boiling, blanching, frying, evaporation, pasteurization, mixing or stirring.

- A unique multifunctional device

- Possibility to cook/fry under atmospheric or vacuum conditions

- Laboratory version of a Vacuum Fryer

- Built-in condensation and secondary steam removal system

- Intense electric heating

- Sectional basket with a lid

- Built-in system for separating and removing excess liquid from the product

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Volume: 20l

- Oil volume: 8l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Stainless steel jam cooking pot with agitator 50l and electric stove 5kW, ideal and affordable cooking solution.

- Heating: Electricity

- Material: Stainless steel

- Engine power, kW: 0,18/

- Heating power, kW: 5

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

We sell many different types of cooking equipment, with a mixer or without, tilting cookers, with capacities from 100 - 350 liters.

- Material: Stainless steel

- Country of origin: EU

Atmospheric cookers ASC are designed for efficient mixing, heating and cooking products for food and cosmetic industries. Volume, l: 100 l.

- Heating: Electricity

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 100l

The cooking boiler is equipped with a jacket for heating as well as a heating system, an electrically driven stirrer (with a geared motor) and Teflon scrapers, which allow for the processing of products with low to medium viscosity. The cooking device is also equipped with a vacuum system.

- Productivity: 100l

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

Price depends on the chosen option. Please send us a request.┬Ā

- Heating: Electricity Steam

- Material: Stainless steel

- Engine power, kW: 2,2

- Volume: 300l

- Dimensions, mm: 1070x1120x1040

The Steam Cooking Pot allows you to cook large batches of your signature soups, stews and pasta as well as steaming and boiling of semi-finished products.

- Heating: Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 200l/ 300l/ 400l

A vacuum cooker is used in the food processing industry to cook ingredients under reduced pressure, typically in a vacuum environment. This method allows for precise temperature control and faster cooking times while preserving the quality and flavor of the ingredients.

We offer different vacuum cookers.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 2500 l

Unbeatable price for highest quality material, modern technology, cylinder design. We offer different capacity catering cookers, electric, steam or gas.

- Heating: Steam

- Material: Stainless steel

- Volume: 150l/ 200l

An evaporating unit is utilized to remove moisture from sweet substances through heating, transforming them into concentrated syrups or solutions.

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Voltage: 380-400V

- Geometric volume: 200 l