Double Z sigma arm mixer

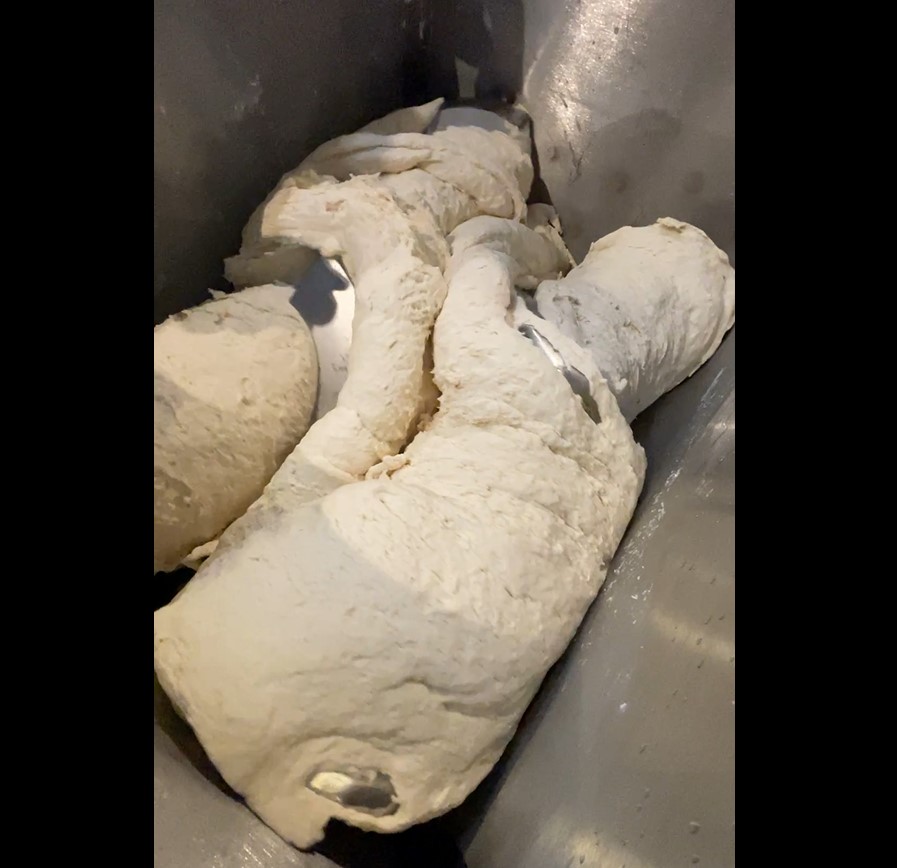

The Z-Sigma Arm paddle mixer is designed for intensive mixing, stirring, kneading and plasticizing products with high and very high viscosity, such as chewing gum base, stiff dough with low water content, toffee mass, soap base, adhesives.

- Double Z-shaped blade

- Very high shear force

- Minimum gap between z blades and the working container

- Independent electric drive for each blade

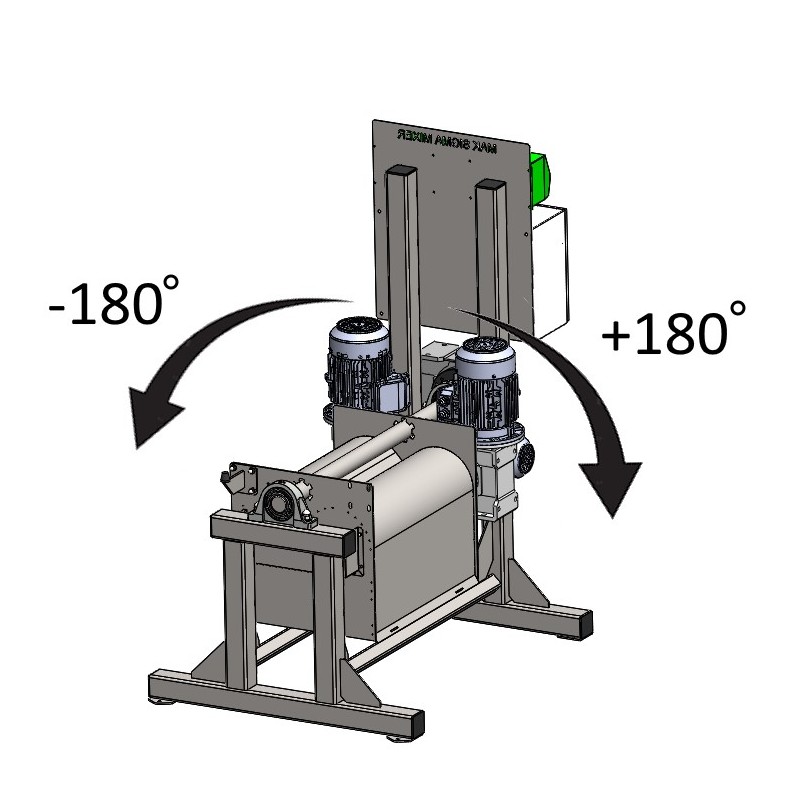

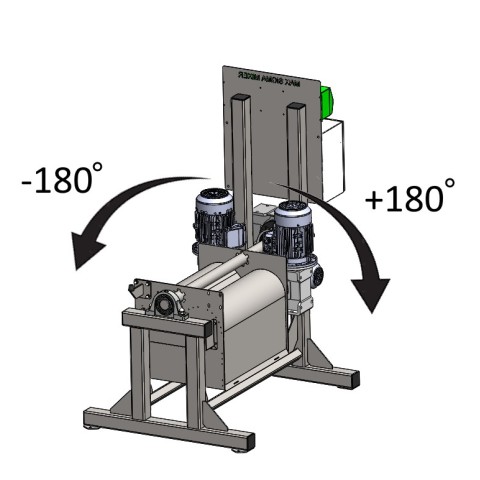

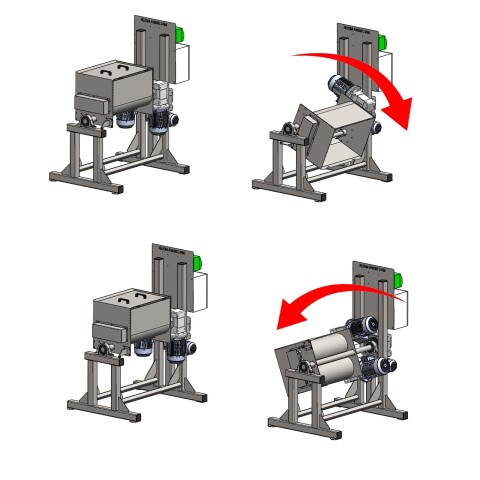

- Electric tilting for automatic unloading up to 180 degrees

- The mixer is made entirely out of food grade stainless steel AISI304

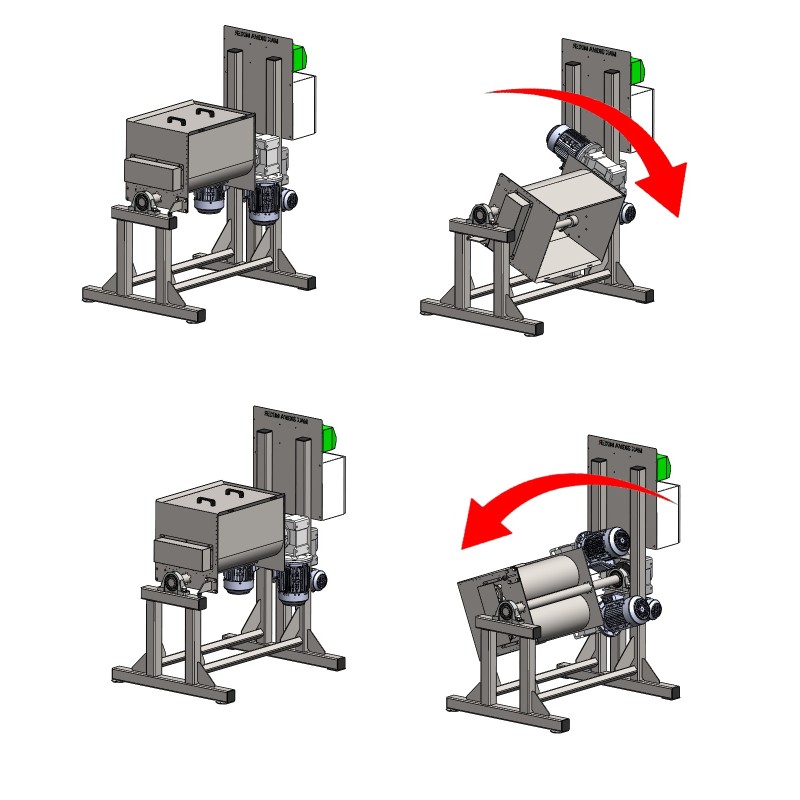

- Possibility to choose the side of tilting and unloading

The multifunctional Z-shape double blade mixer is widely used in various industries: food, chemical, pharmaceutical, cosmetics and many others, where it is necessary to mix complex, heavy, thick and viscous products with a high degree of homogenization. Mainly, double z mixers are used for kneading thick, stiff dough in the confectionery industry as well as in the production of raw, muesli and protein bars, where it is necessary to obtain a thick, homogeneous mixture of cereals, honey, nuts, dried fruits, fondant and so on.

Best for mixing viscious pastes.┬Ā

The Z blade mixer can be used to process and produce products such as:

|

|

|

|

|

|

|

|

|

|

Advantages:

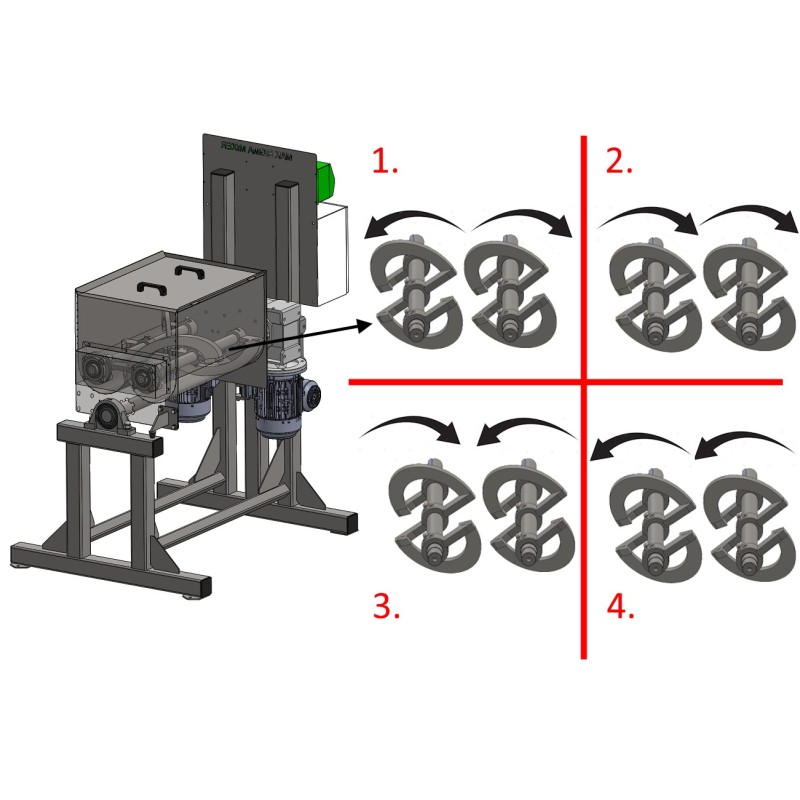

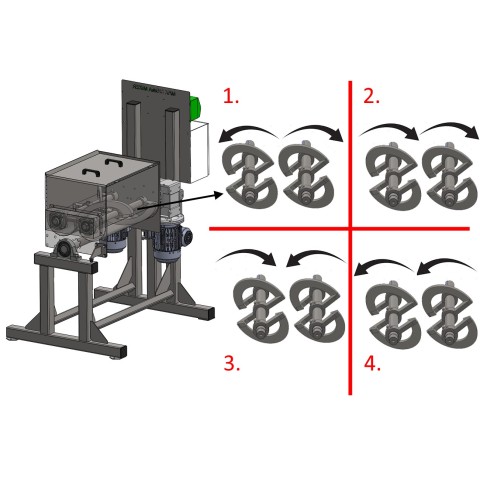

- Independent drive for each Z-shaped blade with the ability to adjust the speed and direction of rotation. For each type of product it is possible to choose its own mixing diagram; each Z blade shaft can rotate in its own direction and at its own speed.

- The ability to choose the side of product unloading, the control system includes both tilting options up to 180 degrees.

- The control is located directly on the mixer; the basic version provides a semi-automat (semi-automatic control panel) with the possibility of individual settings for each system. As an option, an HMI touch screen with semi-automatic control can be installed on the side of the control panel. The HMI panel can be equipped with a memory module for creating and saving recipes.

- The special shape of the working container in the form of a small Greek letter Žē allows for a minimum gap between the walls and the edge of the mixing device blade for highly efficient mixing, including bulk and powder products.

- High degree of safety: lid opening sensors and a working container position sensor, which guarantee safety for operator maintenance.

- Massive supporting structure for the stability of the mixer during operation and reduction of vibration.

- The mixer is made entirely out of food grade stainless steel AISI304; a stainless steel control panel can also be installed as an option.

- Automatic tilting system for the working container, depending on the volume and model, the tilt drive can be electric or hydraulic. Tilting is performed using a joystick mounted on the control panel, up to a maximum tilt angle of 180 degrees.

- Highly economical: mixers with two Z-shaped blades are the optimal choice for both small production and industrial-scale production, as they allow large volumes of product to be efficiently processed in a relatively small area.

- Hygienic design, easy maintenance and cleaning of equipment.

Basic version

The modification of the basic configuration includes a working container suspended on a supporting structure, inside of which special 2 Z-shaped blades, and a mixing device with an independent adjustable electric drive are installed. The working container is equipped with a lid and a control panel. The basic version includes a semi-automatic control panel (semi-automat), which allows you to adjust the direction, speed of rotation of the shafts with z-shaped blades, and automatically tilt the working bowl. In the basic configuration, tilting and unloading can be done in both directions.

Models

| Geometric volume, l┬Ā ┬Ā ┬Ā | Working volume, l┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā | Maximum load, kg┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā┬Ā |

| 70 | 50 | 36-50 |

| 140 | 100 | 70 |

| 460 | 300 | 200 |

| 700 | 470 | 250 |

Options

- Control panel with a HMI panel (touch screen)

- Memory module with the ability to save recipes (when ordering the remote control option with an HMI panel)

- Control panel (electrical cabinet) made out of stainless steel

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 70l/ 140/ 300l/ 460/ 700l/

- Voltage: 380-400V

You might also like

A professional mixer for the production of mayonnaise, sauces, soups and other homogenized products. The price depends on your production capacity, as well as the technological requirements.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 200l

- Total power, kW: 6

The NORMIT drum mixers are designed for thorough mixing for products such as combined feed for animals, infant formulas, baby food, food concentrates and additives, sports supplements and nutrients, coffee, tea, pharmaceuticals and chemical products.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 50l/ 100l/ 150l/ 200l/ 500l

Barrel mixers are used to mix a wide range of loose and granular products in a shipping/barrel container. The available mixer models are suitable for the following volumes:

ConMix 20 - 20-30 liter standard drums with a diameter of 316 mm, adjustable frame structure height

ConMix 75 - 48-65 liter standard barrels with a diameter of 400 mm, adjustable frame structure height

- It is possible to use standard food containers ranging from 20-65 liters

- Easy control via a frequency converter as a stand-alone control panel

- Safe operation thanks to a roll bar with a position sensor

- Engine power, kW: 0,37/ 0,55/ 1,1

- Volume: 20l/ 75/ 100l

The NDM + drum mixer is designed for thorough mixing while retaining the structure of loose products without dead zones and with relatively low consumption and short mixing time. Made for mixing products such as coffee, tea, nutrients and supplements, baby food and many others.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 1000l

The salt dissolving equipment is designed for preparing high-quality marinades, brines with crystal salt, as well as various syrups with the addition of flavor enhancers and essences in small quantities.

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 200l/ 250l/

Paddle Mixer type is designed for fast and precise mixing for meat-mass production in meat processing factories. Can also be used for mixing products such as spices or tea.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 90/ 150l/ 200l/ 300l/ 400l/ 600l/ 850/ 2000 3000

Homogenizer for the production of whipped cream, ice cream, and much more. It allows you to obtain stable liquid emulsions of food mixtures.

- The homogenizer can be installed directly into the container with the product

- High productivity - in just 8 minutes, it is possible to whip up to 60 liters of milk mixture

- The peripheral speed of the knives is 16 m/s

- Material: Stainless steel

- Engine power, kW: 0,37/ 2,2

- Country of origin: EU

- Voltage: 380-400V

Equipment for mixing multi-component mixtures of products, such as vegetable salads with various dressings, including thick and viscous ones like mayonnaise, thick sour cream and other similar sauces.

- Hydraulic tilting system is included in the basic version

- The controls are located directly on the frame supporting structure

- Eccentrically offset working shaft for rotating/tilting the working tank

- Low loading height

- The installation is made entirely out of food grade stainless steel

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 600l/ 1000l

We offer different types of dryers for different products.

- Material: Stainless steel

- Engine power, kW: 2,2

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

Stainlees steel free standing mixer for meat and dough.

- Material: Stainless steel

- Engine power, kW: 0,75 1,1

- Principle of operation: Batch mode

- Volume: 40 60l/ 80l/ 120l

The vacuum cutter is intended for large processing enterprises dealing in the confectionery, fruit and vegetable processing industries. They are intended for processing food down to a homogenous mixture with minimal air content.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Voltage: 380-400V

These meat tumblers are designed for removing air and drawing moisture and marinade into the meat under the conditions of a vacuum.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 600l/ 900/ 1200l/ 2000 3000

A vacuum diffuser is a device used in the food industry to remove oxygen from a product under vacuum conditions, primarily employed for enhancing the preservation of food by reducing oxidation and extending shelf life.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Volume: 200l/ 1000l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

This mixing machine is intended for mixing┬Āsauerkraut with carrots, beets, salt, spices, also for salad, kimchi mixing etc.

- Material: Stainless steel

- Engine power, kW: 2,2

- Volume: 300l/ 600l/

Grinder is used for grinding both fresh meat and food products, such as cheese, fruits.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 380-400V

The vacuum cooking and mixing tank is used to boil products at low temperatures, which helps preserve the natural color, taste and nutrients in the product.

Vacuum equipment is used for cooking premium-quality jams, sauces, fruit and vegetable concentrates.

- Inclined design

- Efficient emptying

- High hygiene standards

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

Butter churner with a volume of 50 L and a usable volume of 25 L for the traditional production of butter from cream.

- Material: Stainless steel

- Engine power, kW: 0,55

- Geometric volume: 50 l

The twinscrew mixer with two horizontal shafts is designed for intensive mixing and kneading dough as well as chocolate, pralines and other similar products with medium or high viscosity.

- Material: Stainless steel

- Engine power, kW: 2,2

- Country of origin: Slovakia

- Weight: 281 kg

- Volume: 500l

The price is indicated with a semi-automatic control panel

The vacuum cooking kettle is designed for use in public catering establishments (restaurants, hotels, catering companies) and small manufacturing businesses. This equipment enables boiling, blanching, frying, evaporation, pasteurization, mixing or stirring.

- A unique multifunctional device

- Possibility to cook/fry under atmospheric or vacuum conditions

- Laboratory version of a Vacuum Fryer

- Built-in condensation and secondary steam removal system

- Intense electric heating

- Sectional basket with a lid

- Built-in system for separating and removing excess liquid from the product

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Volume: 20l

- Oil volume: 8l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar