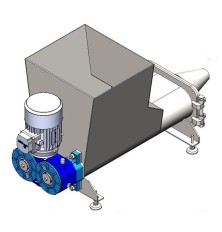

Impeller pump MINI

Monoblock pumps with an integrated frequency converter. We offer many different types of pumps, if you need any advice on which pump to choose, feel free to send us the request.┬Ā

This innovative Mini variable speed impeller pump offers outstanding performance flexibility with exceptional value for money.

The Mini impeller pump is available in two models, the Mini 3/4" and the Midex 1"1/4. The Mini offers capacities between 270 and 1620 liters per hour, and the Midex offers capacities between 1200 and 5760 liters per hour. The variability of the Miniverter range provides a pump that can be used for a wide variety of tasks, reducing the need for expenditure on multiple different sized pumps.

Single phase electrical motors provide speeds between 285rpm and 1400rpm, providing the capability for use at lower speeds with more delicate produce. Stainless steel impeller housings offer cleanliness, high performance and reliability. A range of impeller types in varying flexibilities mean the pumps can be used to transfer a range of products. We offer these pumps with a range of connectors and fittings available - providing full flexibility allowing the pumps to fit straight in to existing production systems.

Pumps in this range can include an optional trolley for ease of transportation, along with a range of other optional extras including radio remote control. Exceptional value offering high performance and reliability.

Mini Impeller pump - Key Features:

- Variable speed for use in a range of situations and with a range of products

- Excellent priming action even at low revolutions, allowing for the transfer of fragile products

- A range of impeller types for use with a range of products

- A range of fittings available to suit individual requirements

- Smooth pumping action without pressure spikes, providing even flow rate

Our impeller pumps are widely used in the:

- OENOLOGICAL field (wine, must and stemmed grapes)

- FOOD processing (beer, fruit pulp and juice, honey, liquid sugar, syrups, glucose, milk, melted butter, yoghurt, liquid eggs, oil, tomatoes pulp and juice , brine, etc.),

- CHEMICAL INDUSTRY (starch, water based glues, emulsions, glycerine, wax, detergents, rubber latex, photographic processing liquids, polyelectrolyte, paints, ink, industrial discharges, etc.),

- COSMETIC and PHARMACEUTICAL production (liquid soap, cleaning lotion, cream, shampoo, etc.).

The rotary pumps are suitable for transfer of delicate, fragile and viscous fluids, also with solid parts in suspension.

Impeller pump - PROCESSES:

- transfer┬Ā

- filling

- emptying

- recycling and mixing

- filtering and separation

- metering

Variable speed impeller pump principle

The flexible impeller vanes deform slightly to pump the liquid inside the pump and move it to the discharge port at a steady flow rate. This principle combines gentle pumping with a high self-priming action.

- Self-priming┬Ā(automatic priming of the product up to 6 m even from dry start-up).

- Reversible operation (the pump can operate in both rotation directions, which permits return of excess liquid without any manual intervention, and also allows easy emptying of pipes on completion of liquid transfer).

- Excellent priming action┬Āeven at a low revolutions, which allows the transfer of soft and fragile fluids with viscosities up to 50.000 cp, or with solid particles in suspension, without causing air-locking, avoiding emulsifying or damaging particles.

- Smooth steady pumping action┬Āof the product without pressure spikes (even flow rate ideal for filling, dosing or filtration).

- The pump can work in all mounting positions.

The easy mounting principle, the multiple choice of production materials and the Quality System procedure applied throughout production, allow us to offer a wide, versatile and customized product range. Every pump range can be produced with different impeller types, mechanical gasket, couplings and in numerous executions, which are: bare shaft pump; coaxial motorized pump (with electric or orbital hydraulic motor); with gearmotor; with pulley (on trolley or base); with mechanical speed variator or with a frequency converter.

- Principle of operation: Continuous mode

You might also like

One of advantages of this glandless pump is very high durability and efficiency in operation in very demanding conditions. We offer glandless pump with different power variations.

- Principle of operation: Continuous mode

Stainless steel low-speed rotary pumps with flexible impeller; particularly suitable for transfer of delicate, fragile and viscous fluids, also with solid parts in suspension.

- Principle of operation: Continuous mode

Centrifugal impeller pumps are ideal for various industrial applications such as food processing, manufacturing, washing and surface treatment of metal pieces, boxes, containers, glass jars and vessels. These pumps are also suitable for dishwashers, bottle washing lines, painting processes, and pumping liquids into various chambers.

- Principle of operation: Continuous mode

The circulation pump for the heating system is a mandatory component for the operation of a flow-through heating system used for heating the water serving as a heat transfer medium inside the duplicator of industrial cooking boilers, mixers, reactors, and vacuum evaporators in food production. It is selected based on the required parameters of the heating system (volume). Our specialists will be happy to assist you in selecting the appropriate pump if you provide the technical specification requirements. This pump is an essential additional component for the flow-through water heater┬Āup to 110┬░C.

- It can be used to circulate water at temperatures up to 110┬░ C

- High efficiency with low power consumption

- Also suitable for central heating systems, heated floors and even for solar systems

- Small connections allow the use of flexible pipes with a smaller diameter

- Type of the equipment: Optional equipment

Stainless steel low-speed rotary pumps with flexible impeller; particularly suitable for transfer of delicate, fragile and viscous fluids, also with solid parts in suspension.

- Principle of operation: Continuous mode

The portable vertical pump is designed for pumping fluent or viscous liquids in the range from 1-2300 m2/s at a temperature of around 25┬░C. The pump cannot be used in potentially explosive atmospheres.

- Material: Stainless steel

- Engine power, kW: 0,25

- Voltage: 380-400V

Designed for pumping hot thermal oil in frying circulation and filtration systems, for oil loading and unloading, in "hot" continuous oil filtration systems with a maximum temperature of up to 200 degrees.

- Material: Stainless steel

- Engine power, kW: 0,55

- Country of origin: Slovakia

Centrifugal impeller pumps are ideal for various industrial applications such as food processing, manufacturing, washing and surface treatment of metal pieces, boxes, containers, glass jars and vessels. These pumps are also suitable for dishwashers, bottle washing lines, painting processes, and pumping liquids into various chambers.

- Principle of operation: Continuous mode

Twin-screw extruder is designed for effective extruding, homogenization, pumping over of plastic masses (butter, margarine, honey, curd products, confectionery mixtures), and forming it into bars and rolls.

- Productivity: 400 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Weight: 115 kg

Vane pumps are used for pumping high viscosity products such as syrups, honey, mayonnaise, sauces, cream and many other products.

- Material: Stainless steel

- Engine power, kW: 2,2

- Type of pump: rotary vane

We offer a wide variety of different pumps for all kinds of liquids, semi-liquid products in various applications.

- Principle of operation: Continuous mode

The screw pump is used for transferring "un-pumpable" products. A great choice for those who work with hard to move liquids and need to move them as quickly as possible.

- Material: Stainless steel

- Voltage: 380-400V

This system is specifically designed for facilitating the direct transfer of pulp to a press.

- Productivity: 2000 kg/h

- Engine power, kW: 0,37

- Weight: 28

- Type of pump: Volumetric, self-priming

We offer different types of pumps for different processes.

- Engine power, kW: 0,37

- Dimensions, mm: 230x190x120

Progressive cavity pumps are used to transfer low and high viscosity products as well as products containing soft particles. They are available in three sizes.

- Material: Stainless steel

- Engine power, kW: 3/ 4

Elliptical rotor pump (three power range models available).

- Material: Stainless steel

- Engine power, kW: 1,8/ 4/ 5,5

- Principle of operation: Continuous mode

Centrifugal pump designed for pumping low viscosity food and aggressive liquids.

- Principle of operation: Continuous mode

We offer different types of pumps for different applications.

- Principle of operation: Continuous mode

Stainless steel low-speed rotary pumps with a flexible impeller; We offer two versions. On base or trolley.

- Principle of operation: Continuous mode