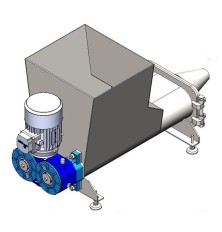

Rotary lobe pump

The lobe rotary pumps are designed for pumping both liquid and thick products. We offer lobe pumps in 2 versions with 1.5 kW is a standard for milk, cream and similar products, and 3 kW is for dense low-flow products such as honey, pastes, cottage cheese etc.

A lobe or a rotary lobe pump is a type of a positive displacement pump.

Lobe pumps are similar to external gear pumps in operation in that fluid flows around the interior of the casing. Unlike external gear pumps, the lobes don't make contact. The pump can be used as an independent unit or as a part of technological line.

It is suitable for pumping the following products:

1.5 kW pump:

- milk

- juice

- syrup

- cream

3 kW pump:

- honey

- heavy cream

- ice cream

- sour cream

- yoghurts

- fermented baked milk

- cottage cheese

- and other fermented milk products of a viscous consistency.

How the pump works

The product is supplied through the suction pipe. Then the product fills the space between the blades. When the rotors rotate, it flows in portions into the discharge pipeline. Reverse rotation of mechanisms is possible according to movement direction of the product. During pumping the structure and consistency of the mixture does not change.

- Engine power, kW: 1,5 / 3

You might also like

One of advantages of this glandless pump is very high durability and efficiency in operation in very demanding conditions. We offer glandless pump with different power variations.

- Principle of operation: Continuous mode

Stainless steel low-speed rotary pumps with flexible impeller; particularly suitable for transfer of delicate, fragile and viscous fluids, also with solid parts in suspension.

- Principle of operation: Continuous mode

Stainless steel low-speed rotary pumps with a flexible impeller; We offer two versions. On base or trolley.

- Principle of operation: Continuous mode

Vane pumps are used for pumping high viscosity products such as syrups, honey, mayonnaise, sauces, cream and many other products.

- Material: Stainless steel

- Engine power, kW: 2,2

- Type of pump: rotary vane

Centrifugal impeller pumps are ideal for various industrial applications such as food processing, manufacturing, washing and surface treatment of metal pieces, boxes, containers, glass jars and vessels. These pumps are also suitable for dishwashers, bottle washing lines, painting processes, and pumping liquids into various chambers.

- Principle of operation: Continuous mode

The homogenizer is designed to homogenize, mix and disintegrate / grind different fluids and components into small particles.

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

The pump provides a delicate straight-streaming pumping of a wide range of liquids with or without solid fragments with viscosity up to 150 Pa.s.

- Material: Stainless steel

- Engine power, kW: 1,1

- Principle of operation: Continuous mode

The portable vertical pump is designed for pumping fluent or viscous liquids in the range from 1-2300 m2/s at a temperature of around 25¬įC. The pump cannot be used in potentially explosive atmospheres.

- Material: Stainless steel

- Engine power, kW: 0,25

- Voltage: 380-400V

The circulation pump for the heating system is a mandatory component for the operation of a flow-through heating system used for heating the water serving as a heat transfer medium inside the duplicator of industrial cooking boilers, mixers, reactors, and vacuum evaporators in food production. It is selected based on the required parameters of the heating system (volume). Our specialists will be happy to assist you in selecting the appropriate pump if you provide the technical specification requirements. This pump is an essential additional component for the flow-through water heater¬†up to 110¬įC.

- It can be used to circulate water at temperatures up to 110¬į C

- High efficiency with low power consumption

- Also suitable for central heating systems, heated floors and even for solar systems

- Small connections allow the use of flexible pipes with a smaller diameter

- Type of the equipment: Optional equipment

This system is specifically designed for facilitating the direct transfer of pulp to a press.

- Productivity: 2000 kg/h

- Engine power, kW: 0,37

- Weight: 28

- Type of pump: Volumetric, self-priming

We offer different types of pumps for different processes.

- Engine power, kW: 0,37

- Dimensions, mm: 230x190x120

Elliptical rotor pump (three power range models available).

- Material: Stainless steel

- Engine power, kW: 1,8/ 4/ 5,5

- Principle of operation: Continuous mode

We offer a wide variety of different pumps for all kinds of liquids, semi-liquid products in various applications.

- Principle of operation: Continuous mode

Monoblock pumps with an integrated frequency converter. We offer many different types of pumps, if you need any advice on which pump to choose, feel free to send us the request.

- Principle of operation: Continuous mode

We sell many types of pumps for many applications and processes. For a free consultation, contact us by sending a request and we will try to recommend the right type of pump for your production.

- Material: Stainless steel

- Type of pump: Centrifugal Stainless Steel Pump

The screw pump is used for transferring "un-pumpable" products. A great choice for those who work with hard to move liquids and need to move them as quickly as possible.

- Material: Stainless steel

- Voltage: 380-400V

The fruit mash pump is designed for efficiently transporting mashed fruits from a crusher to a press for extracting juice.

- Productivity: 6000 kg/h

- Material: Stainless steel

- Engine power, kW: 1,85

- Voltage: 380-400V

This pump is a monoblock single-stage liquid ring vacuum pump suitable for low, medium, and high vacuum applications. It is an economical pump with exceptional performance and reliability.

- Productivity: 52 m3/h

- Principle of operation: Continuous mode