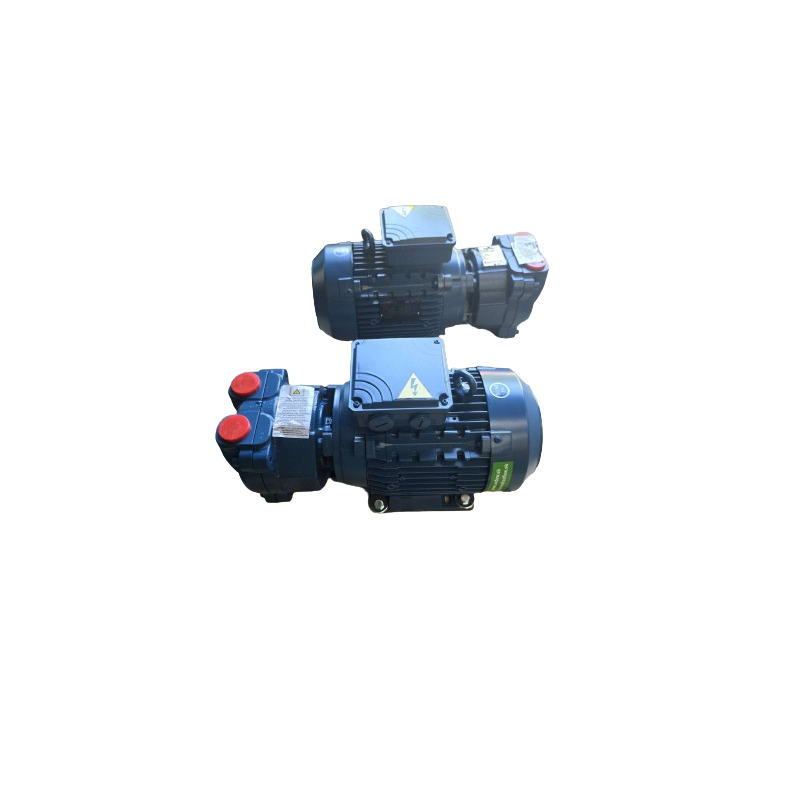

Liquid ring vacuum pump

This pump is a monoblock single-stage liquid ring vacuum pump suitable for low, medium, and high vacuum applications. It is an economical pump with exceptional performance and reliability.

The new hydraulic profile design enables a performance increase of 10% to 20% compared to previous series, enhancing efficiency and reducing operational costs throughout the pump's lifespan.

Compared to the previous series, this pump is 10% lighter and boasts a 10-20% smaller volume, facilitating faster and more cost-effective installations.

Maximum flexibility for handling sealing liquid is achieved. Under standard conditions, this series requires up to 40% less sealing fluid flow than the previous series, leading to significant operating cost savings. For applications requiring the ability to aspirate large sealing liquid flows, pumps are supplied with enhanced higher sealing liquid flow capability.

Stainless steel port plate with laser-cut port profiles ensures wear-free performance and guarantees the execution of optimally designed profiles, enhancing pump working economy.

Innovative anti-cavitation system places the outlet close to the inlet port, improving operational vacuum levels and efficiency across the pump's vacuum range. This solution substantially reduces operational costs.

A series of pumps with different parameters and characteristics are produced.

- Productivity: 52 m3/h

- Principle of operation: Continuous mode

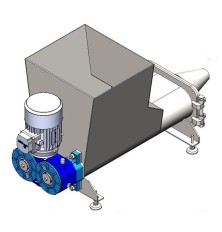

The fruit mash pump is designed for efficiently transporting mashed fruits from a crusher to a press for extracting juice.

- Productivity: 6000 kg/h

- Material: Stainless steel

- Engine power, kW: 1,85

- Voltage: 380-400V

Centrifugal impeller pumps are ideal for various industrial applications such as food processing, manufacturing, washing and surface treatment of metal pieces, boxes, containers, glass jars and vessels. These pumps are also suitable for dishwashers, bottle washing lines, painting processes, and pumping liquids into various chambers.

- Principle of operation: Continuous mode

The single-stage vacuum pumps are versatile, offering a wide range of applications when it comes to transporting liquids due to their simplicity, reliability, and robustness. The device operates with minimal vibrations, and its noise levels do not exceed the prescribed standards. Additionally, it ensures oil-free operation.

The pump provides a delicate straight-streaming┬Āpumping of a wide range of liquids with or without solid fragments with viscosity up to 150 Pa.s.┬Ā

- Material: Stainless steel

- Engine power, kW: 1,1

- Principle of operation: Continuous mode

Stainless steel low-speed rotary pumps with flexible impeller; particularly suitable for transfer of delicate, fragile and viscous fluids, also with solid parts in suspension.

- Principle of operation: Continuous mode

The lobe rotary pumps are designed for pumping both liquid and thick products. We offer┬Ālobe pumps in 2 versions with┬Ā1.5 kW is a standard for milk, cream and similar products,┬Āand 3 kW is for dense low-flow products such as honey, pastes, cottage cheese etc.┬Ā

- Engine power, kW: 1,5 / 3

Centrifugal pump designed for pumping low viscosity food and aggressive liquids.

- Principle of operation: Continuous mode

The homogenizer is designed to homogenize, mix and disintegrate / grind different fluids and components into small particles.

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

Progressive cavity pumps are used to transfer low and high viscosity products as well as products containing soft particles. They are available in three sizes.

- Material: Stainless steel

- Engine power, kW: 3/ 4

One of advantages of this glandless pump is very high durability and efficiency in operation in very demanding conditions. We offer glandless pump with different power variations.

- Principle of operation: Continuous mode

The portable vertical pump is designed for pumping fluent or viscous liquids in the range from 1-2300 m2/s at a temperature of around 25┬░C. The pump cannot be used in potentially explosive atmospheres.

- Material: Stainless steel

- Engine power, kW: 0,25

- Voltage: 380-400V

We offer different types of pumps for different processes.

- Engine power, kW: 0,37

- Dimensions, mm: 230x190x120

The screw pump is used for transferring "un-pumpable" products. A great choice for those who work with hard to move liquids and need to move them as quickly as possible.

- Material: Stainless steel

- Voltage: 380-400V

Twin-screw extruder is designed for effective extruding, homogenization, pumping over of plastic masses (butter, margarine, honey, curd products, confectionery mixtures), and forming it into bars and rolls.

- Productivity: 400 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Weight: 115 kg

Vane pumps are used for pumping high viscosity products such as syrups, honey, mayonnaise, sauces, cream and many other products.

- Material: Stainless steel

- Engine power, kW: 2,2

- Type of pump: rotary vane

We offer different types of pumps for different applications.

- Principle of operation: Continuous mode