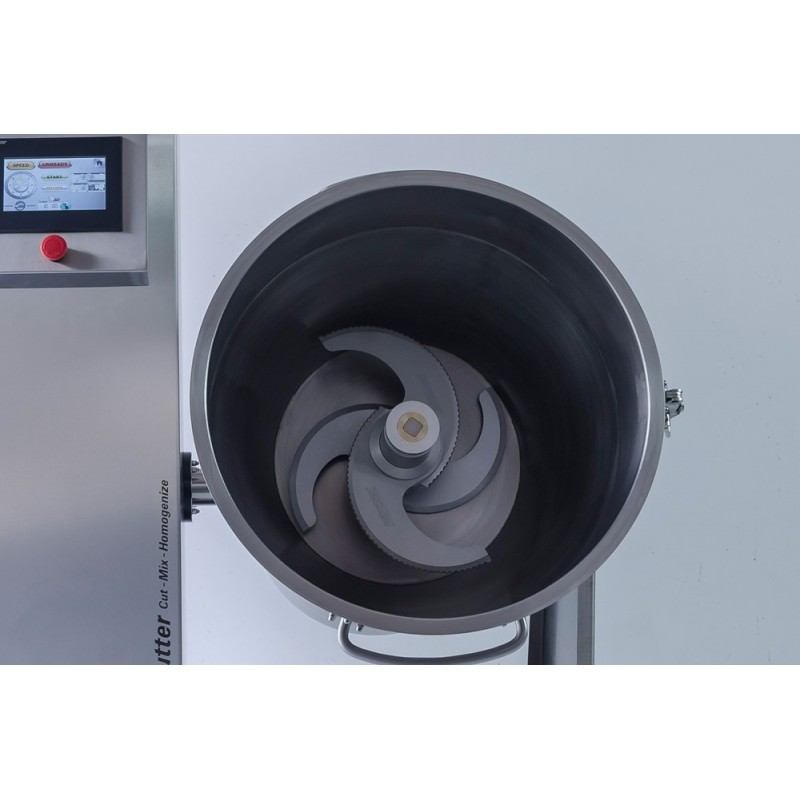

Professional cutter mixer MK 100, 120

100 and 120 liter cutter mixers have been designed for the food industry, pharmaceutical industry and test labs.

Professional cutters mixers for food industry

New models MK 100 and 200 cutters mixers allow our customers to achieve more with less. Allowing our customers to process tremendous amount of products in one batch. It is labor and time saving, fast and convenient.

- Heavy duty machine intended for industrial use

- Cut, mix and homogenize

- Interactive touch control panel

- Full automatic operation

- Removable bowl

Automated Operation Experience

An in-built touch screen is present in the hummus machine makes each operation effortless. The timer, the variable speed function, the reverse revolving function, the cover and tilting mechanism controls are all integrated into the touch panel.┬Ā

Safety standards

Operator safety is at maximum. The Cutter Mixer machine does not start if it does not detect the bowl. Also, the electronic panel of pesto machine runs on a low voltage being complied with the international standards.

Technical features:

- Capacity: 100 lt. / 120 lt.

- Speed: 600-3000 rpm

- Power: 15 kW/18.5 kW

- w x l x h: 100 x 70 x 135 cm

- Capacity/Batch: 75 kg

- Capacity/Hour: 120 kg

- Productivity: 120 kg/h

- Material: Stainless steel

- Engine power, kW: 15/ 18

- Principle of operation: Batch mode

- Volume: 100l/ 120l

You might also like

The vacuum cutter is intended for large processing enterprises dealing in the confectionery, fruit and vegetable processing industries. They are intended for processing food down to a homogenous mixture with minimal air content.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Voltage: 380-400V

The laboratory vacuum cutter mixer is designed for uniform grinding, emulsifying and mixing of food, cosmetic and pharmaceutical products, chemical mixtures with the addition of oil, dyes, concentrates or liquid flavors.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

Atmospheric cutter mixer with capacity of 150l for medium size production of confectionery, chocolate, ice cream, ready meals, cheese, cream smoothie, vegetable puree.

For more information, send us a request.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 150l

This cutter┬Ā as an essential instrument in kitchens, prepares hummus, dressings, herb oils, aromatic butter, thickenings, mayonnaise, sauces, soups, desserts, pure├®s, pates and etc.

- Material: Stainless steel

- Engine power, kW: 2,2/ 3/ 7,5/ 11

- Principle of operation: Batch mode

- Weight: 50 / 85 / 175 / 200

- Volume: 20l/ 30l/ 50l/

- Voltage: 230 V/ 380-400V

- Dimensions, mm: 700 x 480x 1070 / 740 x 480x 1070 / 850 x 580x 1140 / 850x580x1190

The vacuum cutter is intended for large processing enterprises dealing in the confectionery, fruit and vegetable processing industries. They are intended for processing food down to a homogenous mixture with minimal air content.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Voltage: 380-400V

The new design of the universal cutter with gravity mixing is used for the production of thick and pasty products. The cutter is designed to carry out production processes such as cutting, mixing, crushing and emulsifying of various types of products to a liquid state. Thanks to the built-in duplicator, it can also be used as a device for the production of cream honey or cream honey souffl├®.

- Cutting knives with a powerful 11 kW electric drive

- Frame mixing device with fluoroplastic scrapers

- Hatch opening sensor for safe maintenance

- Plexiglass hatch for visual inspection

- Duplicator for the thermal liquid around the bottom as well as the walls of the installation

- Inclined design for efficient grinding, homogenization and discharge of thick and viscous products

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

- Total power, kW: 12

- Voltage: 380-400V

The cutting machine is designed for slicing, shredding and grating fruits and vegetables.

- Productivity: 500 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

- Dimensions, mm: 602x488x1581

The cutter is designed for cutting into cubes, stripes or slices.

- Material: Stainless steel

- Engine power, kW: 2,2

- Principle of operation: Continuous mode

- Voltage: 380-400V

Multifunctional vacuum mixer/homogenizer for grinding, mixing, and homogenizing products to obtain homogeneous masses.

- Built-in jacket for the bottom and walls of the unit.

- Cutter knives with a powerful electric drive

- Slanted design for efficient mixing and chopping

- Forced circulation circuit (optional)

- Wide range of options

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 350l/ 650l

- Total power, kW: 13/ 17

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Atmospheric food processing and cutting machine with a stainless steel design and a 60 L bowl with a cutter (grinding knife)

- Material: Stainless steel

- Engine power, kW: 9,2

- Principle of operation: Batch mode

Atmospheric cutter mixer with capacity of 150l for medium size production of confectionery, chocolate, ice cream, ready meals, cheese, cream smoothie, vegetable puree.

For more information, send us a request.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 150l

Cutter for french fries with an automatic hopper. Approx. 25 kg of French fries 12mm per minute. Cutting blocks are ordered separately.

- Productivity: 1500 kg/h/

- Material: Stainless steel

- Engine power, kW: 0,37

- Dimensions, mm: 360x670x560

The laboratory vacuum cutter mixer is designed for uniform grinding, emulsifying and mixing of food, cosmetic and pharmaceutical products, chemical mixtures with the addition of oil, dyes, concentrates or liquid flavors.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

The high-performance slicing and dicing machine can function as a standalone unit or be integrated into a production line.

- Can process large products - sweet potato, lettuce, root vegetables

- Large selection of replaceable knives - different sizes of the final product

- Material: Stainless steel

The complex of equipment for the production of mayonnaise consists of several installations for automatic dosing, mixing, and obtaining a stable emulsion.

- Compact design, offering convenient and straightforward operation in a limited space.

- Cost-effective solution for automatic dosing without incurring high automation costs.

- A wide range of additional modular options.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Total power, kW: 13,5

- Voltage: 380-400V

Manual cutter for cutting potions of fresh cured meats with interchangeable eccentrics to obtain different sausage lengths up to a maximum of 280 mm. Works with any type of casing.

- Productivity: 100-400 psc/h

- Material: Stainless steel

- Principle of operation: Continuous mode

Chocolate flaking machine for automatically differentiating two blocks of couverture each time. The flakes are collected in plastic baking for food. The machine comes with two plastic bins.

- Productivity: 30 kg/h

- Material: Stainless steel

- Voltage: 220-230V

This 9L cutter is a robust and reliable device used for processing various foods.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 9

- Voltage: 220-230V

This cutter┬Ā as an essential instrument in kitchens, prepares hummus, dressings, herb oils, aromatic butter, thickenings, mayonnaise, sauces, soups, desserts, pure├®s, pates and etc.

- Material: Stainless steel

- Engine power, kW: 2,2/ 3/ 7,5/ 11

- Principle of operation: Batch mode

- Weight: 50 / 85 / 175 / 200

- Volume: 20l/ 30l/ 50l/

- Voltage: 230 V/ 380-400V

- Dimensions, mm: 700 x 480x 1070 / 740 x 480x 1070 / 850 x 580x 1140 / 850x580x1190