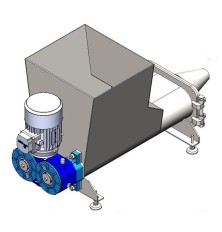

Volumetric professional filling machine for jars and small bottles

This filling machine can even fill high density products as well as products with particles in them. Our dispensing machines are designed with extreme care, and can operate without interruptions.

The machine doses from 200 up to 5000 ml per bottle. The volumetric filler works based on compressed air and does not need electricity or external pumps to aspire the product.

The quantity of the product to be dispensed is filled with constant precision. The dripless valves and dispensing spouts prevent dripping, even with viscous products such as honey, meat sauce, or glue.

The volumetric filler has two modes of operation:

Automatic: automatic product output at regular intervals

Manual: the product is dosed by pressing a pedal controlled by the operator.

You can adjust the pressure, delivery speed, and the suction speed. Easy to assemble, no need for extra tools, easy to clean, maximum precision.

Depending on the viscosity and type of product to be filled, Volumetric filling machine can be customized with a wide range of components:

- Valves for dosing liquid products (water, essential oils, alcoholic and liquid solutions in general)

- Valves for dosing dense products, even with suspended pieces (sauces, creams, jam)

- Shut-off valves for dosing hot-tacked products (honey, glue, and similar products

- Dispensing nozzles for liquid or dense products, with or without anti-drip system

- Product feeding hoppers, with or without integrated automatic mixing and heating systems

Furthermore, the machine is available in bench-top version or on the wheels in order to be easily connected to a storage tank. All parts that come into contact with the product are made of stainless steel AISI 316. For this reason Dosematic Plus can be used in any sector: may this be the food or chemical industry.

Maximum precision of a volumetric filler

The quantity of product is dosed with constant precision. The shut-off valves and dispensing spouts prevent dripping, even with very viscous products such as honey, meat sauce or glue.

Why is volumetric filler easy to use

Filling machine has two modes of operation:

- automatic: the product is emitted at regular intervals

- manual: the product is dosed after pressing a pedal controlled by the operator

What can be regulated

- pressure

- delivery speed

- suction speed

- manual or automatic operation

Filling machine made in EU out of high quality materials

All the parts that come into contact with the product are made of stainless steel AISI 316. For this reason TEPF filler can operate in any sector, be the food or the chemical-pharmaceutical industry.

Dispensable doses┬Ā ┬Ā200 to 5000 ml

- Material: Stainless steel

- Operation mode: Automatic Manual

- Type of the equipment: Individual machine

You might also like

The piston-operated pneumatic liquid dispenser is a semi-automatic filler used for dispensing various low viscosity liquids ranging from 10 to 100 ml in volume.

- Compact tabletop installation

- Simple control with two operating modes: manual and semi-automatic

- Suitable for liquid products with low viscosity (from water to oil)

- Optional compressed air compressor available

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Continuous mode

- Voltage: 220-230V

The piston filler is designed for dosing different types of liquid products in the food, chemical, pharmaceutical and cosmetic industries.

- Material: Stainless steel

- Operation mode: Manual

- Type of the equipment: Individual machine

The manual bottle filler is designed to fill liquids in glass bottles.┬Ā

- Productivity: 650 psc/h

- Material: Stainless steel

- Operation mode: Manual

A range of pneumatic vertical filling machines for dosing liquids with viscosity is similar to water.

- Type of the equipment: Individual machine

Filling and capping machine designed for the filling and capping of liquid or semi-liquid products into flexible doypack bags with a spout.

- Material: Stainless steel

- Voltage: 220-230V

The pneumatic piston filler for pastes and liquids is a semi-automatic dispenser designed for dosing various liquids with a low, medium or high viscosity.

- Tabletop compact model

- Includes a built-in 26 l conical storage tank

- A wide dosing range from 300-2500 ml

- Can also be used for products with a high degree of viscosity

- High dosing speed

- Possibility of working in manual or automatic mode

- Material: Stainless steel

- Principle of operation: Continuous mode

- Volume: 300-2500 ml

- Voltage: 220-230V

Filling and capping machine designed for the filling and capping of liquid or semi-liquid products into flexible doypack bags with a spout.

- Material: Stainless steel

- Voltage: 220-230V

Semi automatic packaging machine for filling and capping jars.

- Material: Stainless steel

This semi-automatic filling machine is used for filling honey as well as other products. We offer many different kinds of filling machines for different applications.

- Material: Stainless steel

- Operation mode: Semi-automatic

- Material: Stainless steel

- Engine power, kW: 0,18/

- Operation mode: Automatic

- Country of origin: EU

- Voltage: 220-230V

VBF is a fast, robust, and versatile vacuum bottle filler.┬ĀThis is the filling machine you are looking for if you desire to increase the production volume of your homemade products, and professionalize the bottling of wine, oil, beer, fruit juices, or other products.

- Operation mode: Semi-automatic

- Principle of operation: Continuous mode

A filler is a device designed for dosing and pumping honey. It guarantees comfortable and professional honey processing.

- Material: Stainless steel

- Engine power, kW: 0,18

- Voltage: 220-230V

Hydraulic sausage filling machine is the ideal equipment to fill sausage of various specifications and is suitable for filling in different kinds of casings.

We offer different meat processing machines.

- Material: Stainless steel

- Engine power, kW: 0,37

- Weight: 92 / 135

- Voltage: 380-400V

The honey dosing machine is a precise filling machine with a gear pump, it is easy to use and is suitable for filling honey as well as a large number of other different liquids - ranging from thinner ones such as drinking yogurt, to high-viscosity products such as mustard.

- Fast operation

- Easy to use

- Easy to clean

- Accuracy

- Compact design

- Productivity: 200 l

We sell many different filling machines for different products.

- Material: Stainless steel

- Country of origin: EU

The piston filler is designed for dosing different types of liquid products in the food, chemical, pharmaceutical and cosmetic industries.

- Material: Stainless steel

- Operation mode: Manual

- Type of the equipment: Individual machine

Hydraulic piston fillers for the food processing industry, filling machines for meat and sausages, ideal equipment for meat industry producers and butchers.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Volume: 20l/ 30l/ 50l

A filling machine for stuffing meat to make sausages. We offer many different dosing machines for different applications.

- Material: Stainless steel

- Operation mode: Manual

- Weight: 27/ 28/ 30

- Dimensions, mm: 710x280x390 / 790x280x390 / 820x280x390 /

A simple mobile filler is an economically advantageous solution for filling barrels. We also offer barrel top filler.

- Material: Stainless steel

The screw pump is used for transferring "un-pumpable" products. A great choice for those who work with hard to move liquids and need to move them as quickly as possible.

- Material: Stainless steel

- Voltage: 380-400V