The mixer is designed for consistent, homogeneous dosing as well as continuous mixing of powders and granules.

Its performance varies from gentle mixing to high-intensity mixing. Intensive mixing occurs at the intersection between the mixing blades. The mixture is circulated from side to side and from one end of the mixer to the other. The mixer depends on the type of model, and can be operated in continuous or batch mode.

In addition to the range of flexibility, the continuous mode offers the potential to improve process control and increase production during operation compared to a batch module. The material is suitable for use in the food industry.

Optional equipment

- As an additional module, it is possible to include a system for dosing liquid mixtures as well as a cleaning system integrated into the cover of the device.

- With regards to flexibility, these mixers also allow for the ability to coat the material with a liquid addition, which is useful for making soups or cake mixes.

Mixing equipment specifications:

- Material: stainless steel

- Geometric volume approx., L: 500

- Recommended working volume approx., L: 300

- Maximum working volume, approx.: L: 400

- Connection: three-phase 400 V

- Material: Stainless steel

- Country of origin: Slovakia

- Voltage: 380-400V

- Geometric volume: 500 l

You might also like

The price depends on the selected modifications and specific options

The plow mixer is often used in the food, pharmaceutical, and chemical industries for mixing and saturating powder products with liquid media in order to obtain a high-quality mixture.

- High intensity and quality of mixing, stirring

- Short mixing time and a high productivity

- Guaranteed repeatability and reproducibility of the product batches

- Gentle handling of the product due to the mixing device's special plows

- A large number of options to choose from to fit a specific product type

- Air Purge Seals

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 700l/ 1200l/ 1800l

- Voltage: 380-400V

Barrel mixers are used to mix a wide range of loose and granular products in a shipping/barrel container. The available mixer models are suitable for the following volumes:

ConMix 20 - 20-30 liter standard drums with a diameter of 316 mm, adjustable frame structure height

ConMix 75 - 48-65 liter standard barrels with a diameter of 400 mm, adjustable frame structure height

- It is possible to use standard food containers ranging from 20-65 liters

- Easy control via a frequency converter as a stand-alone control panel

- Safe operation thanks to a roll bar with a position sensor

- Engine power, kW: 0,37/ 0,55/ 1,1

- Volume: 20l/ 75/ 100l

Suitable for mixing a small amount of dough or meat as well as other thick media.

- Material: Stainless steel

- Engine power, kW: 0,55

- Principle of operation: Batch mode

- Volume: 10l/ 20l

The price is indicated without the frequency converter

A twin-screw mixer for fast and intensive mixing, stirring of bulk solid products, such as granules, muesli with various powder additives.

- The mixing blades carefully move while thoroughly mixing the product

- The mixing mode allows you to move the product cyclically in a circle

- High mixing efficiency due to the counter-movement of the 2 shafts

- Compact design

- Possibility to install scrapers on each blade (optional)

- Reinforced drive, can be used for products saturated with moisture as well

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 500l

- Total power, kW: 3

The appropriate mixing equipment for drum processing depends upon the properties of the products and with the available drum opening.

- Type of the equipment: Individual machine

- Voltage: 230 V/ 380-400V

Meat tumblers are designed to remove air and draw moisture and marinade into the meat under vacuum conditions.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 300l/ 600l/ 900/ 1200l/ 2000 3000

The stirrer for mixing and stirring different types of honey comes with a stainless steel container of 50 and 100 liters. It can also be used for mixing honey during blooming, pasteurization, and controlled crystallization (creaming).

- Powerful electric drive and reinforced stirrer for thick products

- Temperature control to ensure that honey does not overheat above 40 degrees during processing

- The mixing device is also equipped with fluoroplastic scrapers

- All materials in contact with the product are made out of stainless steel

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Principle of operation: Continuous mode

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

Grinder is used for grinding both fresh meat and food products, such as cheese, fruits.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 380-400V

A vacuum cooker is used in the food processing industry to cook ingredients under reduced pressure, typically in a vacuum environment. This method allows for precise temperature control and faster cooking times while preserving the quality and flavor of the ingredients.

We offer different vacuum cookers.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 2500 l

The salt dissolving equipment is designed for preparing high-quality marinades, brines with crystal salt, as well as various syrups with the addition of flavor enhancers and essences in small quantities.

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 200l/ 250l/

The AA50 adjustable industrial mixer is designed for efficient, high-performance mixing of liquid, viscous and pasty products, as well as for dispersing dry ingredients (pigments, dyes and other materials) in a liquid medium to obtain highly dispersed suspensions, emulsions and pastes.

- Material: Stainless steel

Tilting atmospheric cooking kettle is designed for homogeneous cooking and mixing of sauces, smoothies, jams, spreads, soups, pasta, yoghurts, ice cream, curd desserts, mousse, air confectionery masses, pastry cream, fillings for sweets, waffles, rolls, chocolate, gingerbread, cookies, muffins, rolls, pastilla, marshmallows, meringues, marshmallows, brewed dough, sponge cake.

For a price quote, send us a request.

- Heating: Electricity Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

- Voltage: 380-400V

- Geometric volume: 330

- Dimensions, mm: 1700x1030x1500

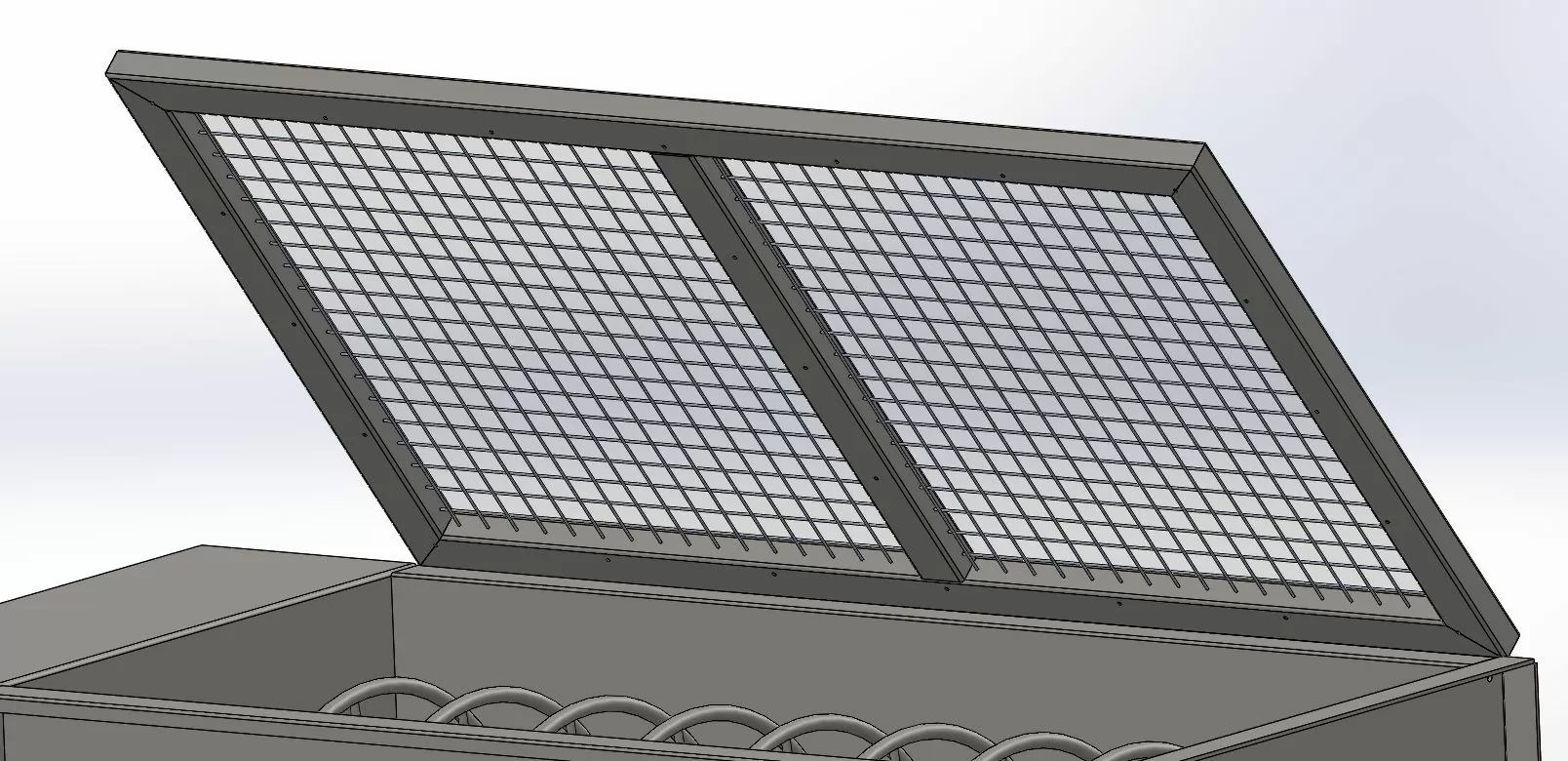

The Economy series of the cooking kettles comprise a thick-walled stainless steel container with an electric mixer mounted on the quick-release upper housing. The installation allows you to mix and stir products during processing. The thick bottom of the pot allows it to be installed on all types of heating surfaces (gas, induction or electric stove).

The Economy version is recommended for use with low-viscosity liquid products; If processing thick and viscous products is necessary, we offer the Premium version of the cooking kettle.

- Sandwich bottom (multilayer) for use on all types of hobs, including induction

- Quick release lid with an electric stirrer

- Safety grid under the upper hull hatch - safe handling when stirring

- Possibility of visual inspection through the safety grid during processing

- Safe loading of components even during mixing

- Material: Stainless steel

- Engine power, kW: 0,12

- Volume: 20l/ 50l/ 100l/ 150l

- Voltage: 220-230V

The price depends on the selected modifications and specific options

The plow mixer is often used in the food, pharmaceutical, and chemical industries for mixing and saturating powder products with liquid media in order to obtain a high-quality mixture.

- High intensity and quality of mixing, stirring

- Short mixing time and a high productivity

- Guaranteed repeatability and reproducibility of the product batches

- Gentle handling of the product due to the mixing device's special plows

- A large number of options to choose from to fit a specific product type

- Air Purge Seals

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 700l/ 1200l/ 1800l

- Voltage: 380-400V

The continuous rotary mixer is a professional solution for mixing, stirring powder and bulk materials.

- Allows precise dosing of components during continuous mixing

- Low energy consumption with high processing volumes

- Made entirely out of stainless steel

- Adjustable working drum tilt

- Special blades for mixing bulk and fragile materials

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

A vacuum diffuser is a device used in the food industry to remove oxygen from a product under vacuum conditions, primarily employed for enhancing the preservation of food by reducing oxidation and extending shelf life.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Volume: 200l/ 1000l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Industrial churning machine available in two capacities. Simple production of butter.

- Geometric volume: 30 l/ 70 l

Suitable for mixing a small amount of dough or meat as well as other thick media.

- Material: Stainless steel

- Engine power, kW: 0,55

- Principle of operation: Batch mode

- Volume: 10l/ 20l

The price is set for the basic version of the installation without additional equipment.

The vacuum homogenizer is designed for a wide range of processes such as for the production of mayonnaise, ketchup, various sauces, confectionery pastes and fillings, liquid or paste like products with a homogeneous structure. It is also suitable for the production of various creams, gels, shampoos and other products in the cosmetic industry.

- Built-in Ultra Shear bottom homogenizer

- Mixing device with movable scrapers

- Tilting version for easy unloading

- Wide range of applications

- Entirely made of food grade stainless steel AISI304/ AISI316 - option

- Compact design

- Lots of additional options to choose from

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 20l/ 50l

- Total power, kW: 2,3/ 2,4

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

A vacuum evaporator is a device used to evaporate liquids at lower temperatures by creating a vacuum environment, which reduces the boiling point of the liquid and enables efficient evaporation without thermal degradation of sensitive materials. Working volume up to, l: 1900 l.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: up to 1900 l