The mixer is designed for consistent, homogeneous dosing as well as continuous mixing of powders and granules.

Its performance varies from gentle mixing to high-intensity mixing. Intensive mixing occurs at the intersection between the mixing blades. The mixture is circulated from side to side and from one end of the mixer to the other. The mixer depends on the type of model, and can be operated in continuous or batch mode.

In addition to the range of flexibility, the continuous mode offers the potential to improve process control and increase production during operation compared to a batch module. The material is suitable for use in the food industry.

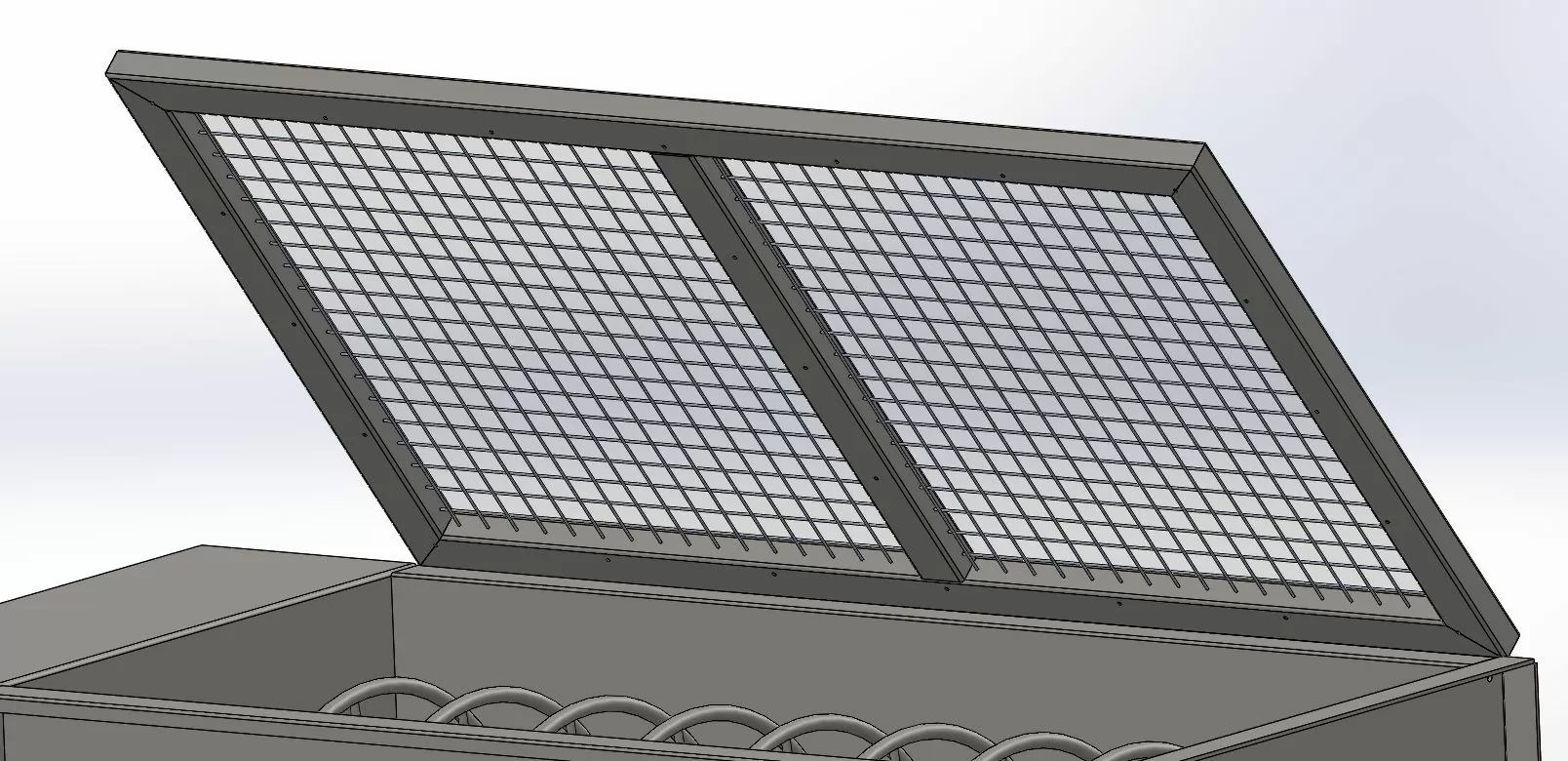

Optional equipment

- As an additional module, it is possible to include a system for dosing liquid mixtures as well as a cleaning system integrated into the cover of the device.

- With regards to flexibility, these mixers also allow for the ability to coat the material with a liquid addition, which is useful for making soups or cake mixes.

Mixing equipment specifications:

- Material: stainless steel

- Geometric volume approx., L: 500

- Recommended working volume approx., L: 300

- Maximum working volume, approx.: L: 400

- Connection: three-phase 400 V

- Material: Stainless steel

- Country of origin: Slovakia

- Voltage: 380-400V

- Geometric volume: 500 l

You might also like

Barrel mixers are used to mix a wide range of loose and granular products in a shipping/barrel container. The available mixer models are suitable for the following volumes:

ConMix 20 - 20-30 liter standard drums with a diameter of 316 mm, adjustable frame structure height

ConMix 75 - 48-65 liter standard barrels with a diameter of 400 mm, adjustable frame structure height

- It is possible to use standard food containers ranging from 20-65 liters

- Easy control via a frequency converter as a stand-alone control panel

- Safe operation thanks to a roll bar with a position sensor

- Engine power, kW: 0,37/ 0,55/ 1,1

- Volume: 20l/ 75/ 100l

Suitable for mixing a small amount of dough or meat as well as other thick mixtures.

- Material: Stainless steel

- Engine power, kW: 0,55

- Principle of operation: Batch mode

- Volume: 10l/ 20l

The price is indicated without the frequency converter

A twin-screw mixer for fast and intensive mixing, stirring of bulk solid products, such as granules, muesli with various powder additives.

- The mixing blades carefully move while thoroughly mixing the product

- The mixing mode allows you to move the product cyclically in a circle

- High mixing efficiency due to the counter-movement of the 2 shafts

- Compact design

- Possibility to install scrapers on each blade (optional)

- Reinforced drive, can be used for products saturated with moisture as well

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 500l

- Total power, kW: 3

The continuous rotary mixer is a professional solution for mixing, stirring powder and bulk materials.

- Allows precise dosing of components during continuous mixing

- Low energy consumption with high processing volumes

- Made entirely out of stainless steel

- Adjustable working drum tilt

- Special blades for mixing bulk and fragile materials

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The price is indicated with a semi-automatic control panel

The vacuum cooking kettle is designed for use in public catering establishments (restaurants, hotels, catering companies) and small manufacturing businesses. This equipment enables boiling, blanching, frying, evaporation, pasteurization, mixing or stirring.

- A unique multifunctional device

- Possibility to cook/fry under atmospheric or vacuum conditions

- Laboratory version of a Vacuum Fryer

- Built-in condensation and secondary steam removal system

- Intense electric heating

- Sectional basket with a lid

- Built-in system for separating and removing excess liquid from the product

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Volume: 20l

- Oil volume: 8l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Vacuum paddle mixers are designed for fast and precise mixing meat-mass in a vacuum. Used in meat production in meat processing factories.┬Ā

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 150l/ 200l/ 300l/ 400l/ 600l/ 850/ 3000

A cooking kettle and a vacuum mixer for periodic deaeration of products such as mayonnaise, ketchup, various sauces, creams, gels and pastes. It is one of the modifications of a vacuum reactor and a vacuum evaporator. The presence of a vacuum system allows you to create a vacuum after the cooking process and perform vacuuming (deaeration) to remove air bubbles with potential contaminants and obtain a product with a denser structure. Thanks to vacuuming, the product has an extended shelf life, since pathogens and microbes contained within are removed together with the air.

- Inclined design with gravity mixing, which is 30% more efficient than usual

- 100% emptying of the product after processing due to the bottom valve

- Easy to disassemble removable mixing device

- Possibility of connecting it to a CIP station for cleaning and washing

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l

- Total power, kW: 0,12

- Max vacuum: -0,8 Bar

The cooking boiler is equipped with a jacket for heating as well as a heating system, an electrically driven stirrer (with a geared motor) and Teflon scrapers, which allow for the processing of products with low to medium viscosity. The cooking device is also equipped with a vacuum system.

- Productivity: 100l

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

The twinscrew mixer with two horizontal shafts is designed for intensive mixing and kneading dough as well as chocolate, pralines and other similar products with medium or high viscosity.

- Material: Stainless steel

- Engine power, kW: 2,2

- Country of origin: Slovakia

- Weight: 281 kg

- Volume: 500l

Shaker mixer SMU6 is designed for mixing the contents of packaged products that are in foil or other protective packaging. The device is used in the food, pharmaceutical, chemical, construction and cosmetic industries, where it is necessary to thoroughly mix the contents without damaging the packaging.

- No need to remove the product from the packaging - mixing takes place in the original packaging

- Hygienic and safe mixing without contamination

- Robust and durable construction made of stainless steel AISI 304

- Material: Stainless steel

- Country of origin: Slovakia

Tilting atmospheric cooking kettle is designed for homogeneous cooking and mixing of sauces, smoothies, jams, spreads, soups, pasta, yoghurts, ice cream, curd desserts, mousse, air confectionery masses, pastry cream, fillings for sweets, waffles, rolls, chocolate, gingerbread, cookies, muffins, rolls, pastilla, marshmallows, meringues, marshmallows, brewed dough, sponge cake.

For a price quote, send us a request.

- Heating: Electricity Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

- Voltage: 380-400V

- Geometric volume: 330

- Dimensions, mm: 1700x1030x1500

Multifunctional vacuum mixer/homogenizer for grinding, mixing, and homogenizing products to obtain homogeneous masses.

- Built-in jacket for the bottom and walls of the unit.

- Cutter knives with a powerful electric drive

- Slanted design for efficient mixing and chopping

- Forced circulation circuit (optional)

- Wide range of options

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 350l/ 650l

- Total power, kW: 13/ 17

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Round cooking boiling pan combines together the advantages of cooking with automatic mixing. Designed for catering industry, school kitchens, restaurant kitchens or food industry. Capacity ranges from 100l to 500l. The available heating options are - steam boiling or indirect electric heating.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 150l/ 200l/ 300l/ 500l

These meat mixers are characterized by their modern design and strong AISI 304 stainless steel construction.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 50l/ 110 l/ 163 l/ 250l/

Universal cooking kettle with a built-in mixer, used for cooking and stirring a variety of food products, cosmetic emulsions, creams and much more.

- Easily removable self-adjusting scrapers

- Lid opening sensor for safe stirrer maintenance

- Hygienic temperature sensor for the product

- Large diameter outlet valve

- Safe steam outlet on top of the boiler lid

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

We offer wide range of catering equipment for restaurants, canteens and all kinds of food serving establishments. Price depends on the chosen option.

- Heating: Gas Steam

- Productivity: 300 l 600 l 1000 l

- Operation mode: Automatic

- Type of the equipment: Individual machine

Planetary mixers are primarily used in the confectionary industry. Offered in three different capacities.

- Material: Stainless steel

- Engine power, kW: 1,5 / 2,2

- Principle of operation: Batch mode

A honey homogenizer is a batch-type device designed to improve the product's structure and organoleptic properties. It ensures a uniform consistency and stable texture of honey.

Homogenization is a processing technology that makes honey flowable and uniform, as well as inhibits crystal growth, thus meeting the needs of producers and consumers. The design, size, and angle of the rotary auger achieve a high level of homogenization, which also reduces raw material processing time.

- High level of homogenization, aimed at increasing stability and improving the honey's structure without altering the product's flavor.

- No dead spots or corners due to the inclined bottom of both the working tank and the auger mixer.

- The working tank is equipped with a jacket and a built-in water heating system.

- Large-diameter outlet valve installed at the lowest hydraulic point.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Total power, kW: 4/ 7

- Loading, kg: 500/ 1100

Butter churner with a volume of 50 L and a usable volume of 25 L for the traditional production of butter from cream.

- Material: Stainless steel

- Engine power, kW: 0,55

- Geometric volume: 50 l