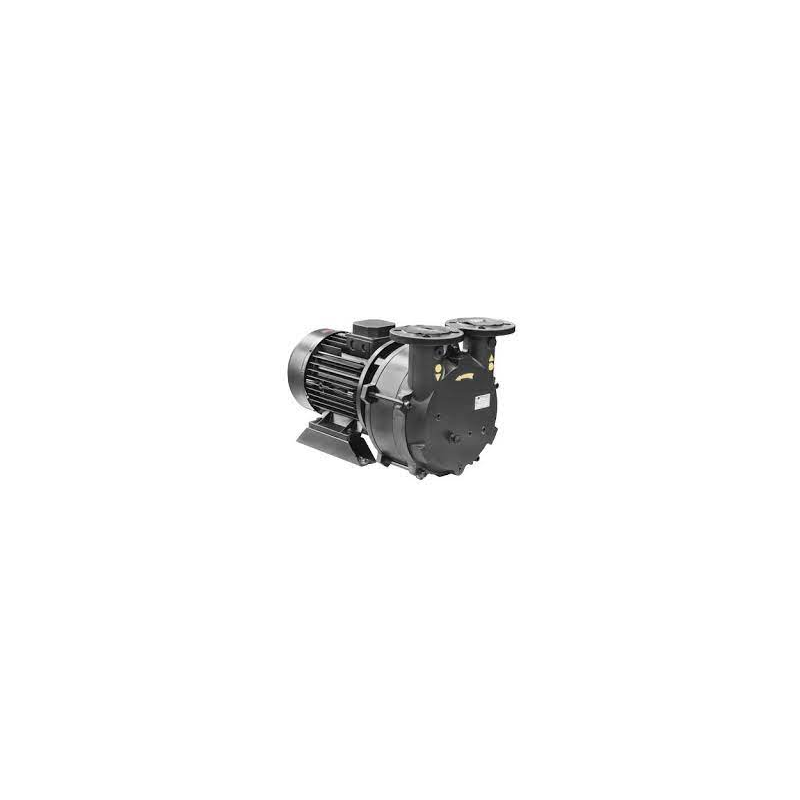

Vacuum ring pump 0,75 KW

The single-stage vacuum pumps are versatile, offering a wide range of applications when it comes to transporting liquids due to their simplicity, reliability, and robustness. The device operates with minimal vibrations, and its noise levels do not exceed the prescribed standards. Additionally, it ensures oil-free operation.

The pump features a monoblock construction, directly mounted on the motor flange in compliance with the B3/B5 standard. It is driven by a flexible coupling.

Shaft support is ensured by two ball bearings lubricated for life, while the shaft seal adopts a single-acting mechanical seal according to DIN 24960 (standard material selection C/SiC/Viton). The pump is made primarily out of cast iron, it includes stainless steel components such as the impeller and the connection to the plate.

Application

- Bottle filling

- Evaporation/distillation

- Vacuum processing

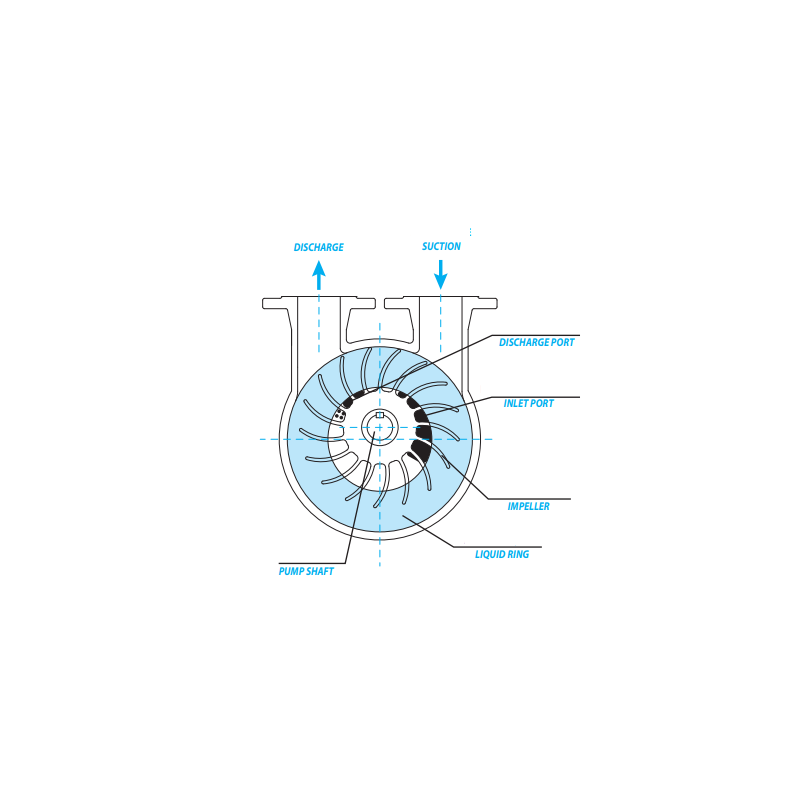

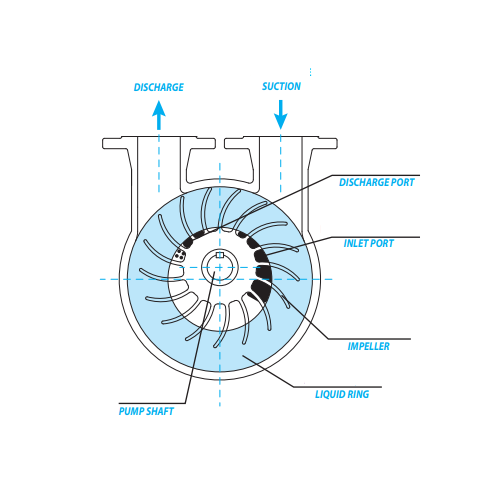

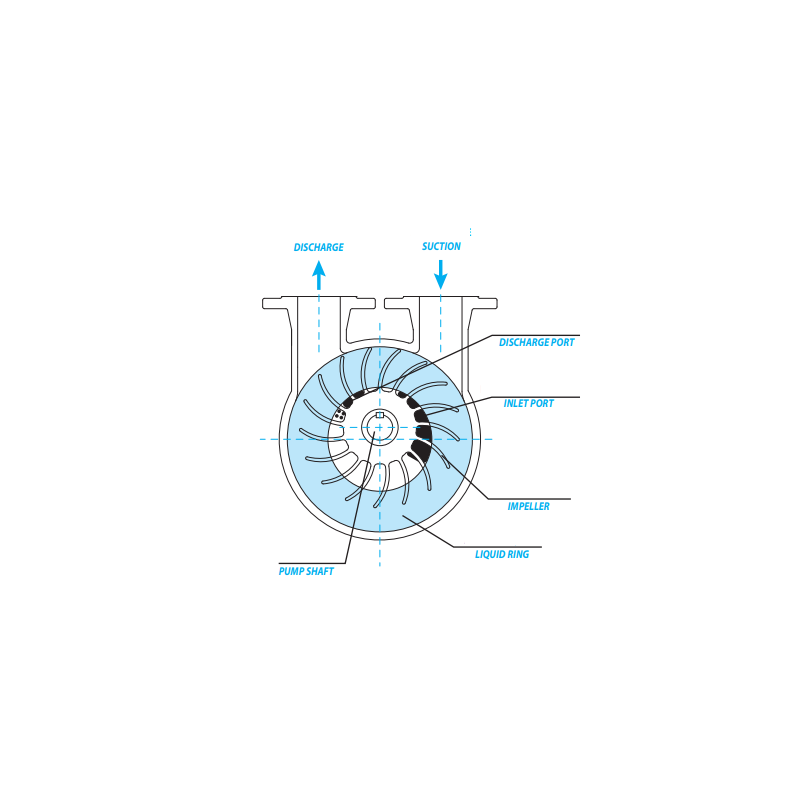

Operation

During operation, it is essential to feed the pump with a liquid, typically water. This is crucial to maintain the stable rotating piston effect and facilitate the removal of the heat load generated during the compression of the pumped gas mixture.

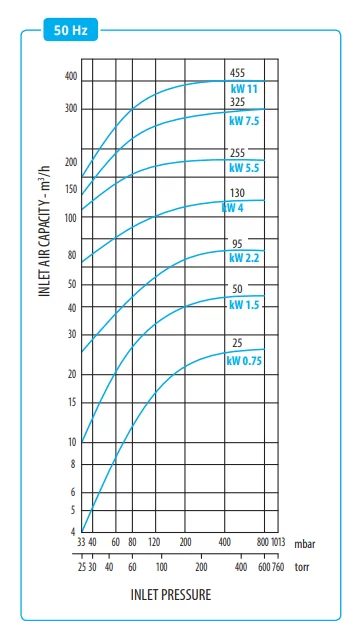

The following performance curves showcase the pump's efficiency under various conditions:

┬Ā

┬Ā

The curves' values are based on the use of 15┬░C water as the service liquid, drawing in ambient air composed of dry and rarefied air at an ambient temperature of 20┬░C. The atmospheric pressure is set at 1013 mbar. For enhanced vacuum performance, a gas ejector can be installed in front of the pump, utilizing the pressure difference created by the pump.

The ejector's operational range should ideally stay below 40 mbar, with a minimum achievable suction pressure of 10 mbar.

Technical parameters

|

┬ĀRPM ┬Ā |

Suction pressure┬Ā(abs. mbar) 40┬Ā ┬Ā ┬Ā ┬Ā ┬Ā 200┬Ā ┬Ā ┬Ā ┬Ā 600┬Ā ┬Ā |

Compressor ┬Ā |

Max. permitted amount of liquid through the suction nozzle (m3/h) continuous┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā discontinuous |

| 2850 | 0,4┬Ā ┬Ā ┬Ā ┬Ā ┬Ā0,4┬Ā ┬Ā ┬Ā ┬Ā 0,33 | 0,28 | 0,5┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā0,6 |

| 3500 | 0,4┬Ā ┬Ā ┬Ā ┬Ā ┬Ā0,4┬Ā ┬Ā ┬Ā ┬Ā 0,33 | 0,28 | 0,5┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā0,6 |

┬Ā

Dimensions:

The high-performance screw pump is used for pumping both thick and viscous food products, as well as various masses containing pieces or solid inclusions such as in the cosmetics, cosmetology, and other industries.

- High performance

- All parts in contact with the product are made out of AISI304

- Does not damage products containing solid pieces

- Additional options: by-pass

- Material: Stainless steel

- Engine power, kW: 1,1/ 1,5 / 3

- Principle of operation: Continuous mode

Twin-screw extruder is designed for effective extruding, homogenization, pumping over of plastic masses (butter, margarine, honey, curd products, confectionery mixtures), and forming it into bars and rolls.

- Productivity: 400 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Weight: 115 kg

Electric continuous flow heaters in different designs and performance parameters.

- Heating: Electricity

- Material: Stainless steel

- Country of origin: Slovakia

- Type of pump: sealless pump

This pump is a monoblock single-stage liquid ring vacuum pump suitable for low, medium, and high vacuum applications. It is an economical pump with exceptional performance and reliability.

- Productivity: 52 m3/h

- Principle of operation: Continuous mode

The fruit mash pump is designed for efficiently transporting mashed fruits from a crusher to a press for extracting juice.

- Productivity: 6000 kg/h

- Material: Stainless steel

- Engine power, kW: 1,85

- Voltage: 380-400V

We offer different types of pumps for different processes.

- Engine power, kW: 0,37

- Dimensions, mm: 230x190x120

Progressive cavity pumps are used to transfer low and high viscosity products as well as products containing soft particles. They are available in three sizes.

- Material: Stainless steel

- Engine power, kW: 3/ 4

This system is specifically designed for facilitating the direct transfer of pulp to a press.

- Productivity: 2000 kg/h

- Engine power, kW: 0,37

- Weight: 28

- Type of pump: Volumetric, self-priming

The lobe rotary pumps are designed for pumping both liquid and thick products. We offer┬Ālobe pumps in 2 versions with┬Ā1.5 kW is a standard for milk, cream and similar products,┬Āand 3 kW is for dense low-flow products such as honey, pastes, cottage cheese etc.┬Ā

- Engine power, kW: 1,5 / 3

Vane pumps are used for pumping high viscosity products such as syrups, honey, mayonnaise, sauces, cream and many other products.

- Material: Stainless steel

- Engine power, kW: 2,2

- Type of pump: rotary vane

Stainless steel low-speed rotary pumps with flexible impeller; particularly suitable for transfer of delicate, fragile and viscous fluids, also with solid parts in suspension.

- Principle of operation: Continuous mode

Stainless steel low-speed rotary pumps with a flexible impeller; We offer two versions. On base or trolley.

- Principle of operation: Continuous mode

We offer different types of pumps for different applications.

- Principle of operation: Continuous mode

We sell many types of pumps for many applications and processes. For a free consultation, contact us by sending a request and we will try to recommend the right type of pump for your production.

- Material: Stainless steel

- Type of pump: Centrifugal Stainless Steel Pump

Designed for pumping hot thermal oil in frying circulation and filtration systems, for oil loading and unloading, in "hot" continuous oil filtration systems with a maximum temperature of up to 200 degrees.

- Material: Stainless steel

- Engine power, kW: 0,55

- Country of origin: Slovakia

The screw pump is used for transferring "un-pumpable" products. A great choice for those who work with hard to move liquids and need to move them as quickly as possible.

- Material: Stainless steel

- Voltage: 380-400V